Orthorhombic manganese ore material and preparation method thereof, negative electrode and lithium battery

A technology of orthorhombic manganese and ore, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of negative electrode materials with low lithium content, rising material synthesis costs, and lack of lithium resources, etc., and achieve good electrical conductivity, low cost, The effect of saving lithium resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] This embodiment is used to illustrate the LiVTiO provided by the invention 4 Materials and their method of preparation (solid-phase method).

[0056] In a dry atmosphere, weigh V at a molar ratio of 1:1:1 2 o 3 、TiO 2 , Li 2 CO 3 Each 0.615g, 0.655g, 0.303g. Mix evenly in a mortar, and then mix in a mixer with a rotating speed of 2000rpm-2800rpm for 10-20 minutes to obtain a mixture of the two. The mixture was then compressed into a tablet precursor on a tablet press with a pressure of 60 Mp. In a tube furnace, in a nitrogen atmosphere, the above precursor was heated from room temperature to 950 °C at a rate of 5 °C / min, kept at 950 °C for 10 hours, and then naturally cooled to room temperature to obtain a black solid. Its scanning electron microscope pictures are as Figure 7 , it can be seen that the particle size of the prepared material is between 1 and 20 μm. LiVTiO prepared from Fig. 4 The X-ray diffraction results of the material ( Figure 8 ) and refi...

Embodiment 2

[0059] This embodiment is used to illustrate the LiVTiO provided by the invention 4 Electrochemical properties of materials.

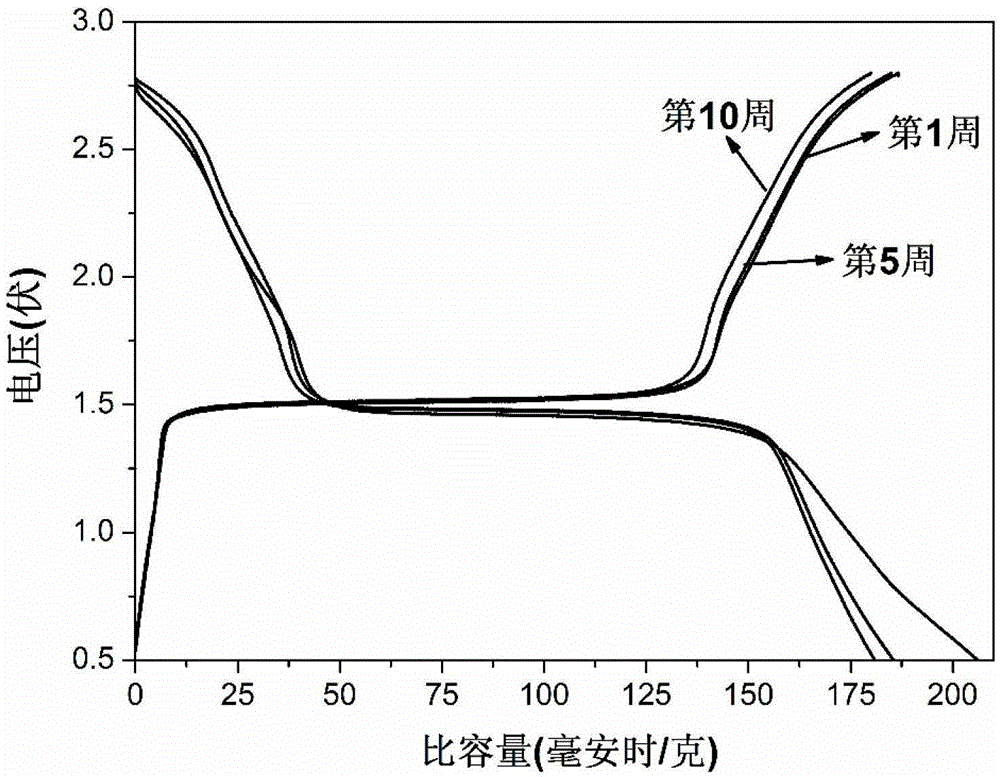

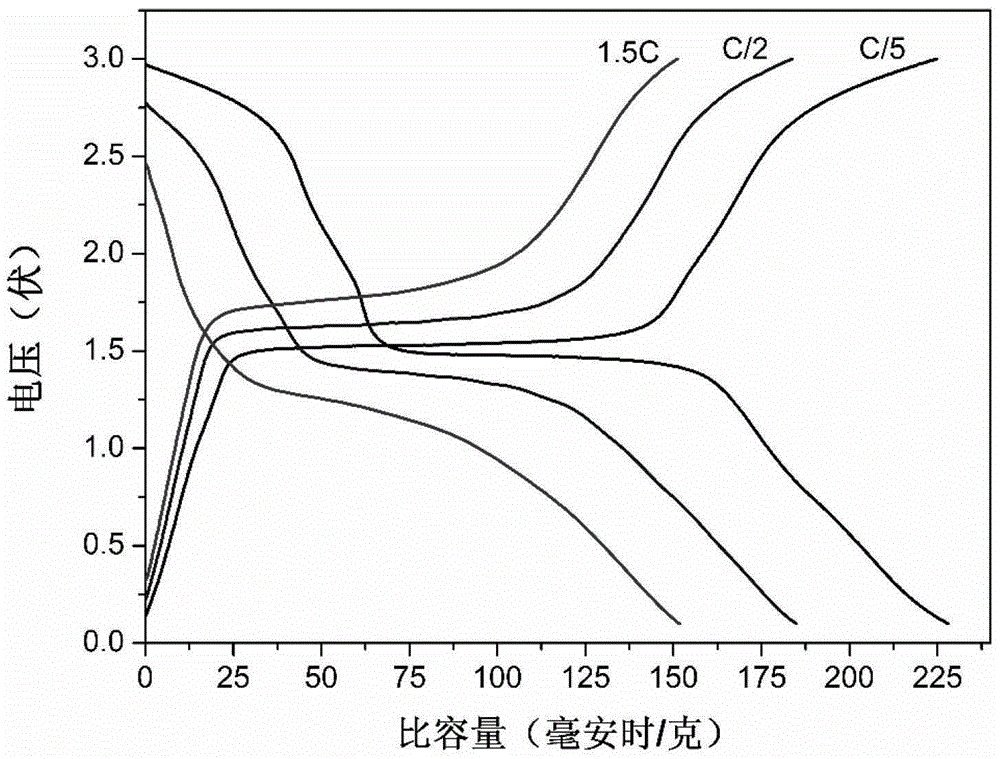

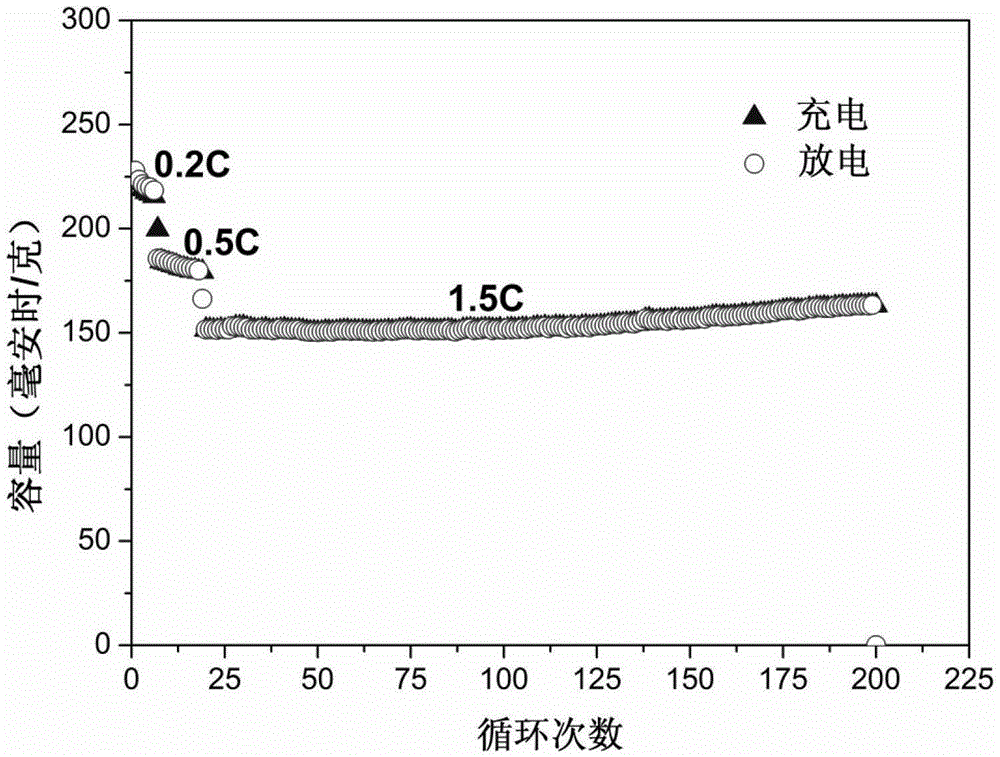

[0060] The above-mentioned negative electrode active material is prepared into a lithium ion battery. The specific steps are: the prepared negative electrode active material LiVTiO 4 Mix the powder with acetylene black and binder PVDF in a weight ratio of 80:10:10, add an appropriate amount of NMP solvent, grind in a dry environment at room temperature to form a slurry, and then evenly coat the slurry on the current collector copper foil , cut into 8×8mm pole pieces after drying, dried at 100°C for 10 hours under vacuum conditions, and then transferred into a glove box for later use. The assembly of the simulated battery was carried out in an Ar atmosphere glove box, with metal lithium sheet as the counter electrode, 1M LiPF 6 / EC+DEC (ethylene carbonate + diethyl carbonate) solution is used as the electrolyte and assembled into a CR2032 button batt...

Embodiment 3

[0063] This embodiment is used to illustrate the LiV provided by the invention 0.99 Cr 0.01 TiO 4 Materials and their method of preparation (solid-phase method).

[0064] In a dry atmosphere, weigh V 2 o 3 、TiO 2 , Li 2 CO 3 、Cr 2 o 3 Each 0.615g, 0.655g, 0.300g, 0.003g. Mix well in a mortar, and then mix in a mixer with a rotation speed of 2000rpm-2800rpm for 10-20 minutes. The mixture was then compressed into a tablet precursor on a tablet press with a pressure of 60 Mp. In a tube furnace, in a nitrogen atmosphere, the above precursor was heated from room temperature to 950 °C at a rate of 5 °C / min, kept at 950 °C for 8 hours, and then naturally cooled to room temperature to obtain a black solid.

[0065] The assembly of the positive electrode, negative electrode, electrolyte and battery of the simulated battery prepared by the method of Example 1 is the same as in Example 1, and its first week charge-discharge curve is listed in Figure 12 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com