Automatic hemostasis pressing device

A technology of tourniquet and pressing part, which is applied in the field of automatic hemostatic press, can solve problems such as difficulties, achieve the effects of reducing operation actions, realizing automatic supply, and avoiding the disinfection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

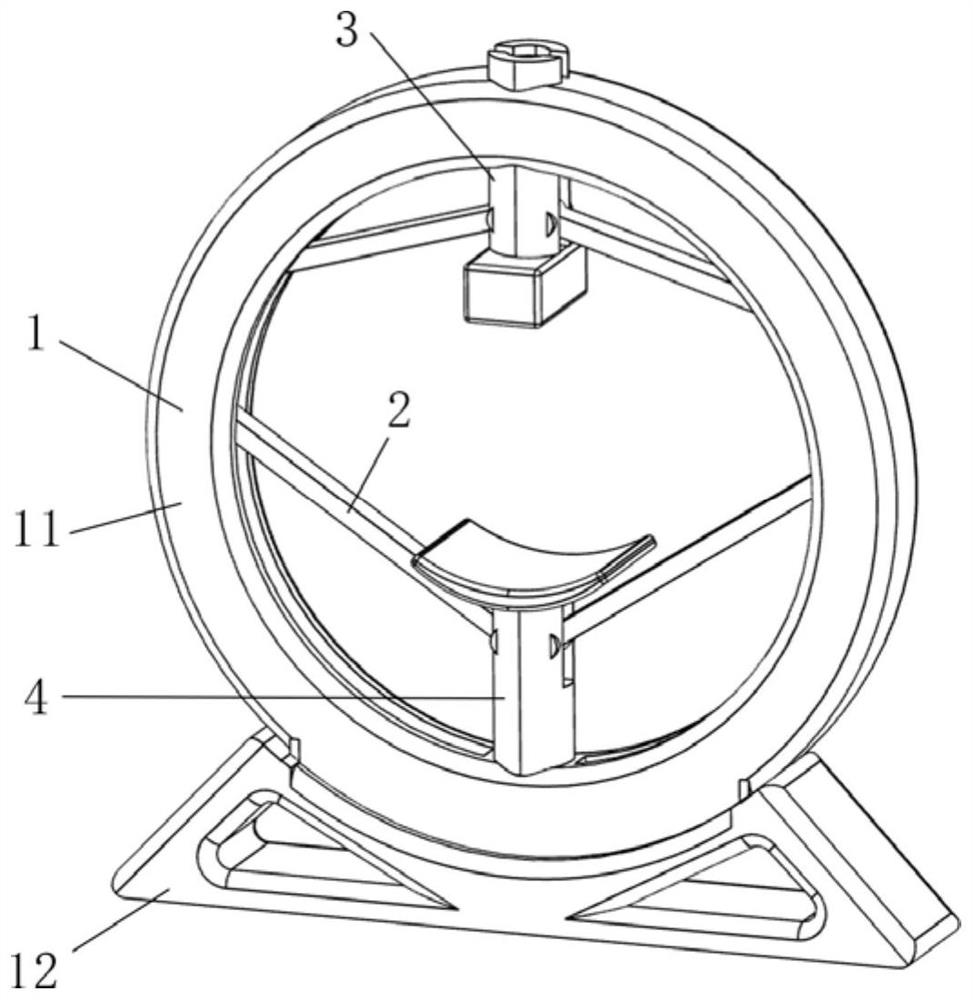

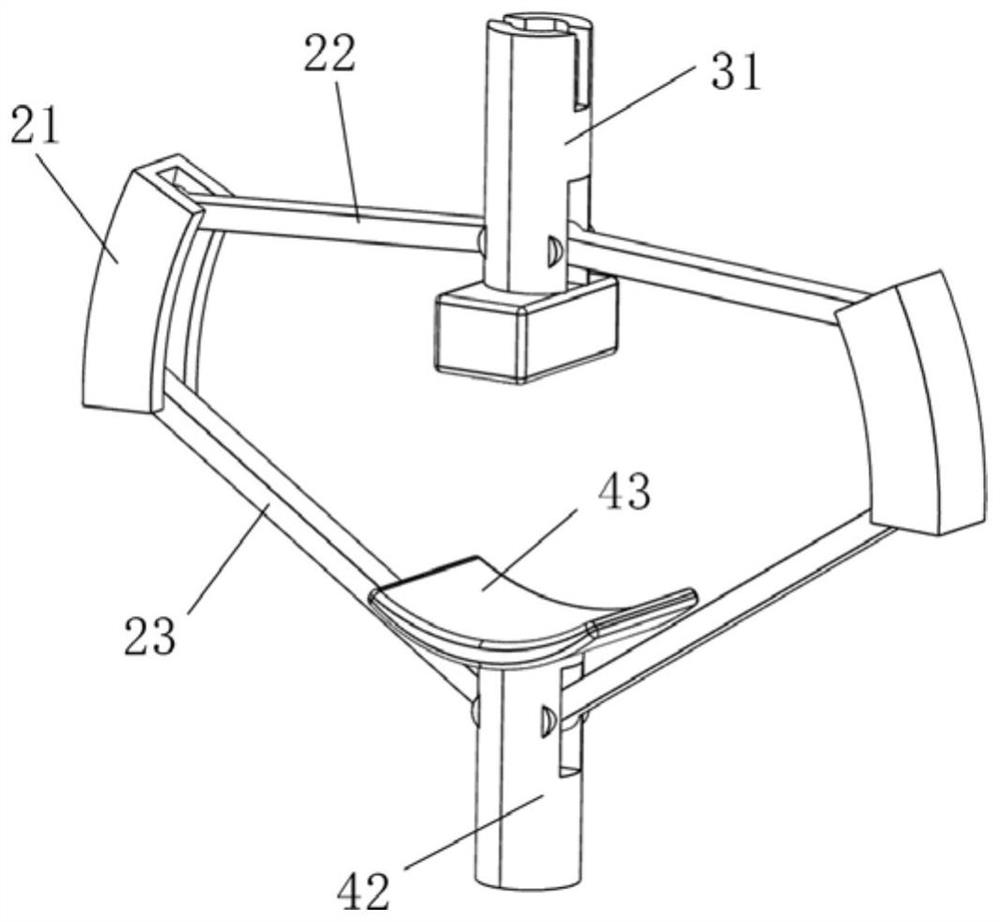

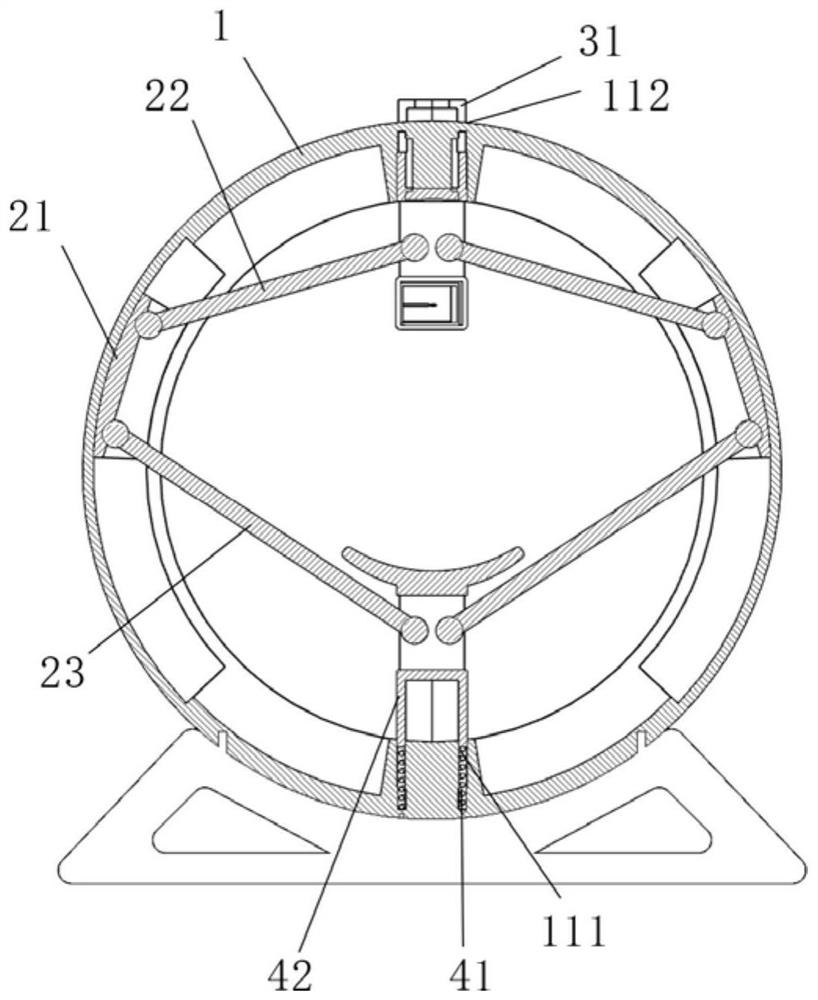

[0029] like Figure 1 ~ 3 As shown, this embodiment provides an automated hemostatic pressor, including a bracket module 1, a transmission module 2, an arm pressing module 3, and an arm support module 4.

[0030] The bracket module 1 includes a base 12 and an annular rail frame 11, and the annular rail frame 11 is disposed vertically on the base 12, and the interior of the annular track frame 11 is a cavity, forming a track; the base 12 is in a hollow triangle shape, the interior is divided into two Part, while reducing material cost, the load-bearing structure is optimized, and the integration of the device is also improved.

[0031] The arm pressing module 3 and the arm support module 4 are respectively disposed at the top and bottom of the annular rail frame 11, and can be extended up and down within the annular rail frame 11. Specifically, the arm support module 4 includes a hand plate 43, a reset spring 41, and an arm support frame 42. A mounting groove 111 is provided with a ...

Embodiment 2

[0035]The basic configuration and examples of the present embodiment are the same, and the distinction point is that the arm pressing module 3 includes a pressing mechanism 32, which is mounted at the bottom of the arm pressing module 3, such as Figure 5 Sum Figure 6 Indicated. The pressing mechanism 32 includes a pressing push rod 321, a first motor 322, and an ultrasonic sensor. The first motor 322 drives the push rod 321 up and down by a gear structure, and the bottom end of the push rod 321 is a suction cup 321a, and an existing vacuum suction cup is employed. The ultrasonic sensor is mounted on the edge of the pressing push rod 321 to detect whether the lower arm is within the set distance.

[0036] The work procedure and principle of the present embodiment are: first draw a stop bose under the suction cup 321a during use. When the arm pressing module 3 drops, the ultrasonic sensor responds and starts monitoring. When the ultrasonic sensor detects that the first motor 322 sta...

Embodiment 3

[0038] This embodiment is an improved type of the second embodiment, and the arm pressing module 3 also includes a hemostatic belt replacement unit 33, such as Figure 7 Indicated. The hemostatic belt replacement unit 33 includes a pulley 332 and a second motor 331. The second motor 331 is connected to the rotation shaft of the pulley 332, and the hemostasis 5 is wound around the pulley 332, and the hemostasis replacement unit 33 is provided with an outlet groove 333 toward the pressing push rod 321 such that the one end of the hemostasis 5 passes through the outlet tank. 333. The hemostasis 5 is connected to a hemostasis having a protective film, and adjacent hemostasis is a virtual electrical connection. The knife can be provided in the lower side of the outlet 333. When the pressing work is over, the second motor 331 can drive the pulley 332 to extend the hemostatic belt 5 outlet groove 333. The suction cup 321a of the pressing push rod 321 activates the hemostatic belt 5, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com