Production device of peanut crisps

A production device and a technology for peanut crisps, which are applied in the field of food or food materials, can solve the problems of not crispy peanut crisps, low efficiency, bad taste, etc., and achieve the effects of high production efficiency and good taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below by means of specific embodiments:

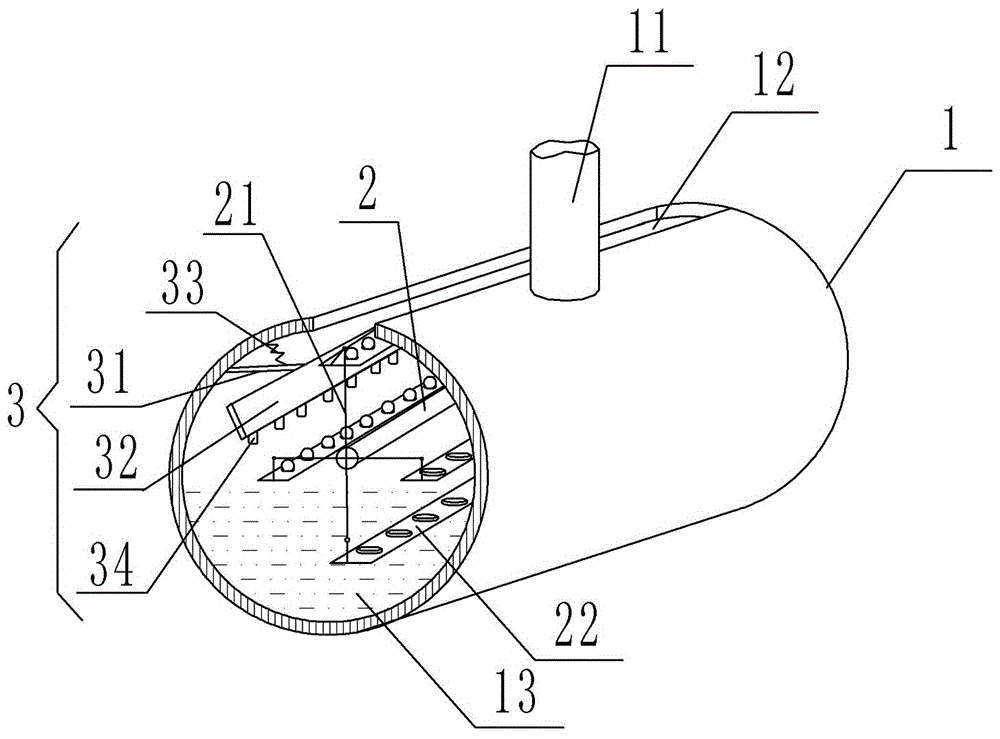

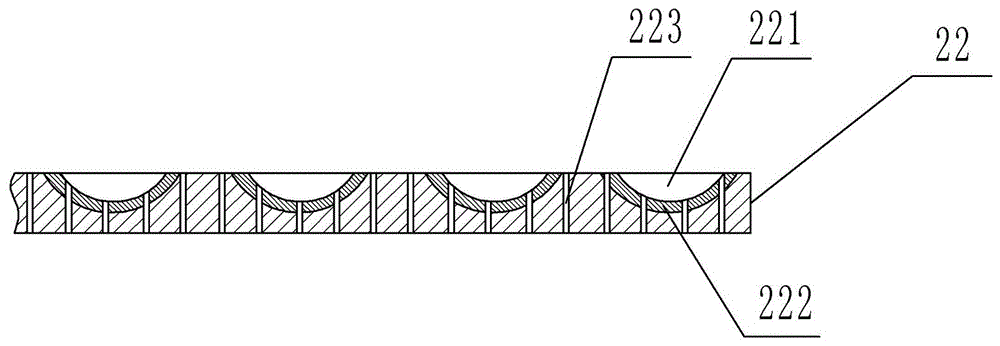

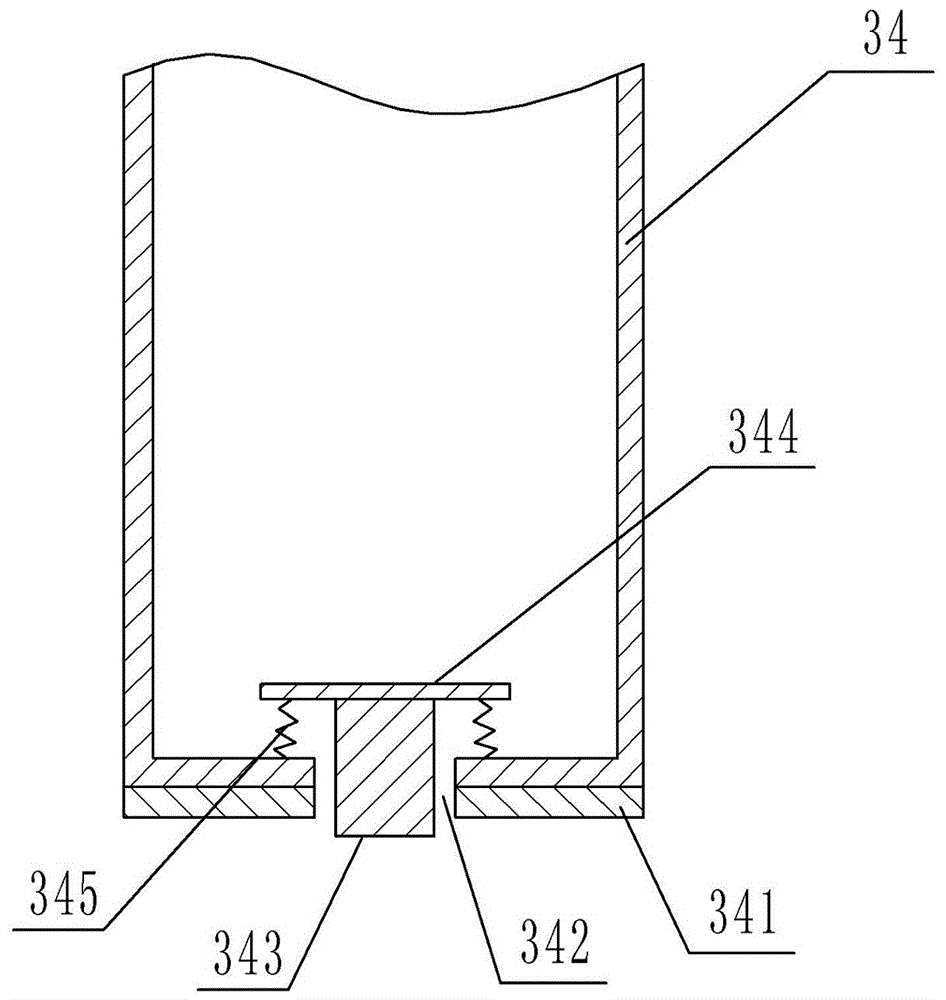

[0031]The reference signs in the drawings of the description include: production box 1, oil fume duct 11, access opening 12, oil chamber 13, rotating shaft 2, rotating shaft support 21, storage board 22, concave cavity 221, magnet 222, mesh 223, press Press 3, support rod 31, pressing plate 32, spring 33, pressing protrusion 34, electromagnet 341, sesame hole 342, push rod 343, baffle plate 344, extension spring 345.

[0032] see figure 1 As shown, a device for making peanut crisps includes a making box 1 and an oil fume duct 11 arranged on the upper part of the making box 1, and the making box 1 is cylindrical, and the inside of the making box 1 is a hollow structure. The production box 1 is provided with a pick-and-place opening 12 for picking and placing peanut crisps. The bottom of the production box 1 is an oil chamber 13, and the outer wall of the oil chamber 13 (t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com