Spray freeze dryer capable of controlling particle size of nano powder

A technology of spray freeze-drying and nano-powder, which is applied in the direction of nanotechnology, nanotechnology, liquid separation into beads and granulation, etc. It can solve the problems of uneven material quality and uncontrollable freezing rate, and achieve improved heat transfer uniformity, improved Uniformity, the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

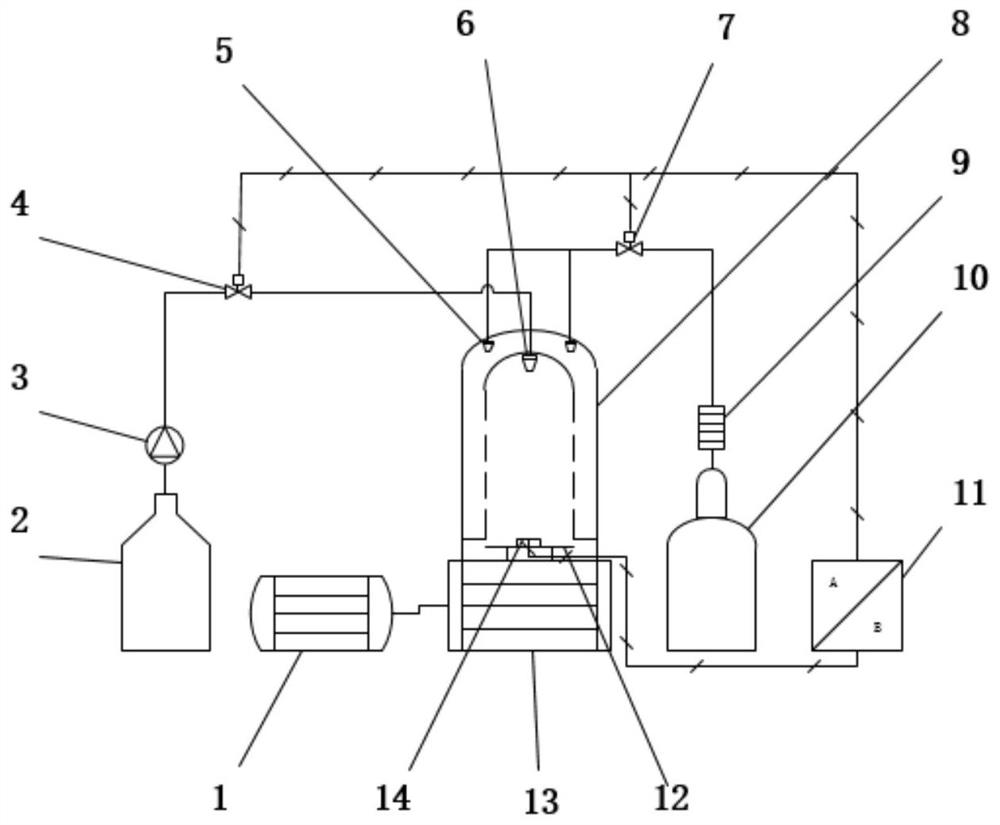

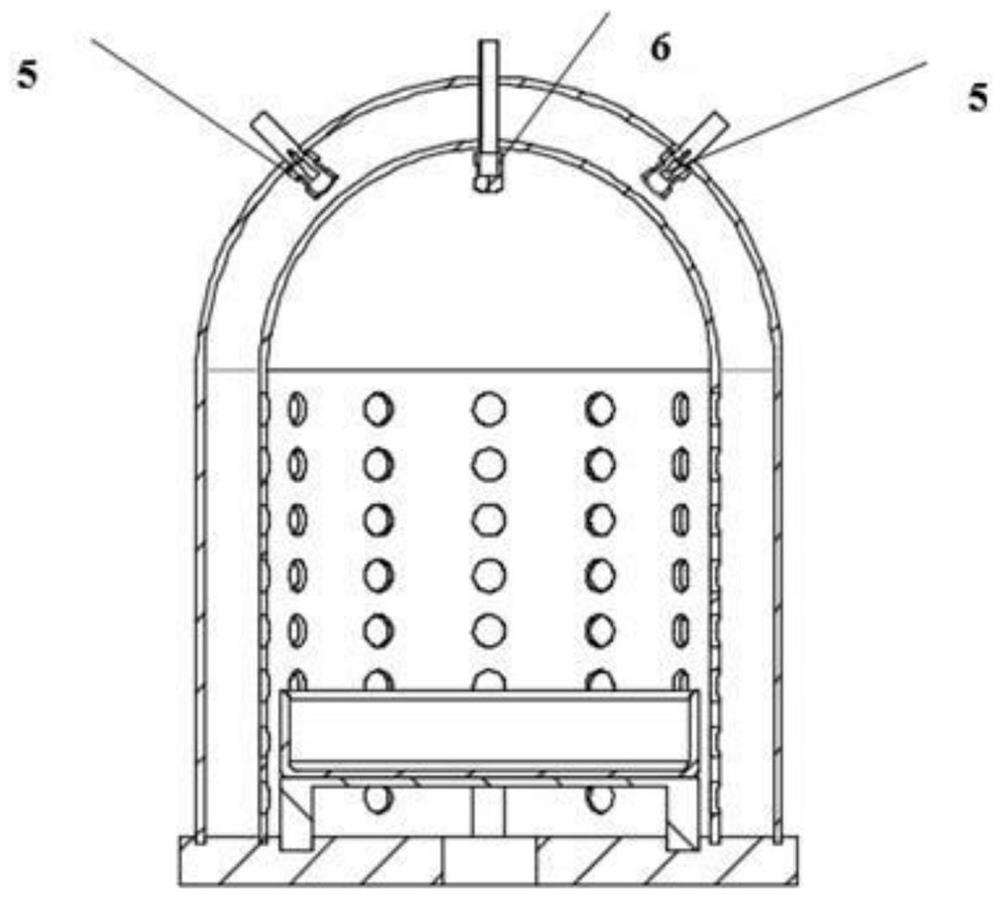

Method used

Image

Examples

Embodiment 1

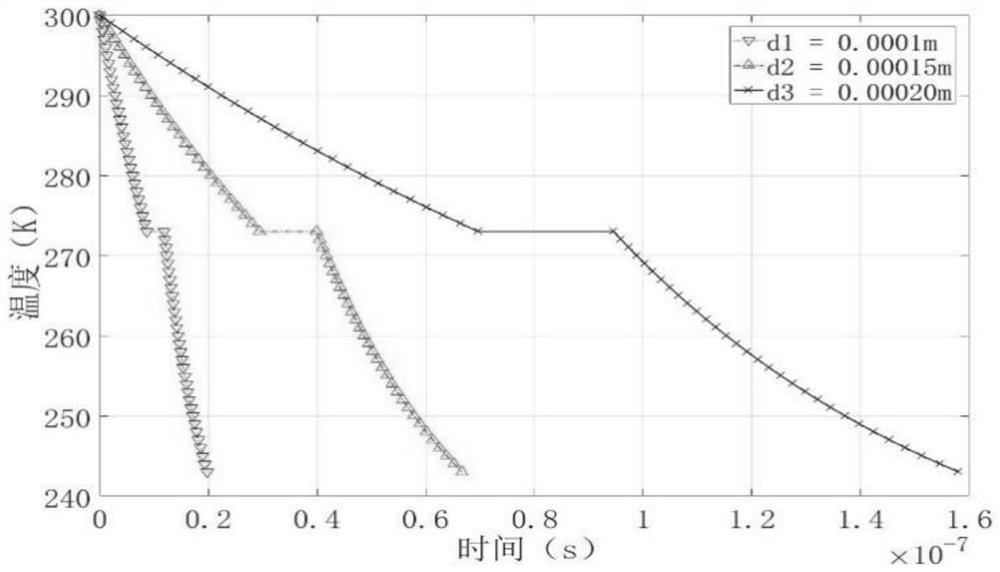

[0032] The precursor solution of copper is carried out freeze-drying, when described equipment is used, comprises the following steps:

[0033] Step 1: Import all the obtained solution into the material tank, first set the equipment temperature parameters on the control end instrument, set the freezing temperature to -90°C, the drying temperature (the drying standard is: the room temperature of the equipment's environment), and the diameter is 0.5mm atomizing nozzle, and then start the system equipment;

[0034] Step 2: Turn on the controller 11, and the system first opens the nitrogen valve 7. At this time, the nitrogen gas will be atomized and enter the freeze-drying chamber 8. After the temperature in the freezing chamber drops to the set value, the system will automatically open the material valve 4; After the atomization enters the freezing chamber, it will condense under low temperature, and the system will adjust the material valve 4 and nitrogen valve 7 accordingly acc...

Embodiment 2

[0037] The precursor solution of copper is carried out freeze-drying, when described equipment is used, comprises the following steps:

[0038] Step 1: Import all the obtained solution into the material tank, first set the equipment temperature parameters on the control end instrument, set the freezing temperature to -120°C, the drying temperature (the drying standard is: the room temperature of the equipment's environment), and the diameter is 0.4mm atomizing nozzle, and then start the system equipment;

[0039] Step 2: Turn on the controller 11, and the system first opens the nitrogen valve 7. At this time, the nitrogen gas will be atomized and enter the freeze-drying chamber 8. After the temperature in the freezing chamber drops to the set value, the system will automatically open the material valve 4; After the atomization enters the freezing chamber, it will condense under low temperature, and the system will adjust the material valve 4 and nitrogen valve 7 accordingly ac...

Embodiment 3

[0042] The precursor solution of copper is carried out freeze-drying, when described equipment is used, comprises the following steps:

[0043] Step 1: Import all the obtained solution into the material tank, first set the equipment temperature parameters on the control end instrument, set the freezing temperature to -150°C, and the drying temperature (the drying standard is: the room temperature of the environment where the equipment is located), and the diameter is 0.3mm atomizing nozzle, and then start the system equipment;

[0044]Step 2: Turn on the controller 11, and the system first opens the nitrogen valve 7. At this time, the nitrogen gas will be atomized and enter the freeze-drying chamber 8. After the temperature of the freezing chamber drops to the set value, the system will automatically open the material valve 8; After the atomization enters the freezing chamber, it will condense under low temperature, and the system will adjust the material valve 4 and nitrogen ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap