Soil pollution treatment device

A soil pollution and soil remediation technology, which is applied in the field of soil pollution control, can solve problems such as difficulty in spraying, easy to be evaporated gradually, and uneven mixing of soil remediation fluid, so as to improve the mixing effect, improve the mixing efficiency, and improve the efficiency of soil remediation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

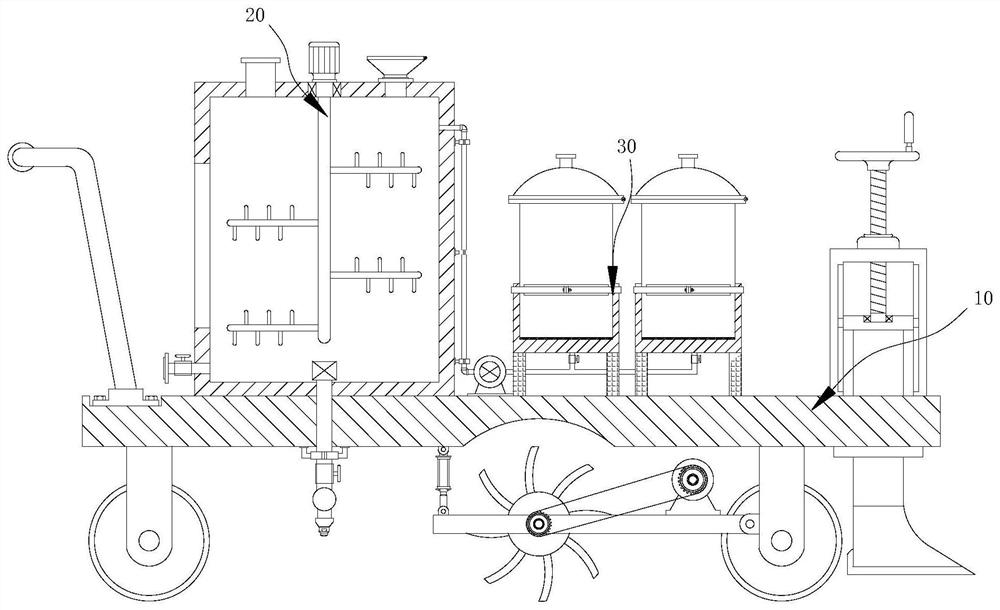

[0033] see Figure 1-5 , the present invention provides a technical solution: a soil pollution control device, including a soil turning mechanism 10 and a mixing and spraying mechanism 20 .

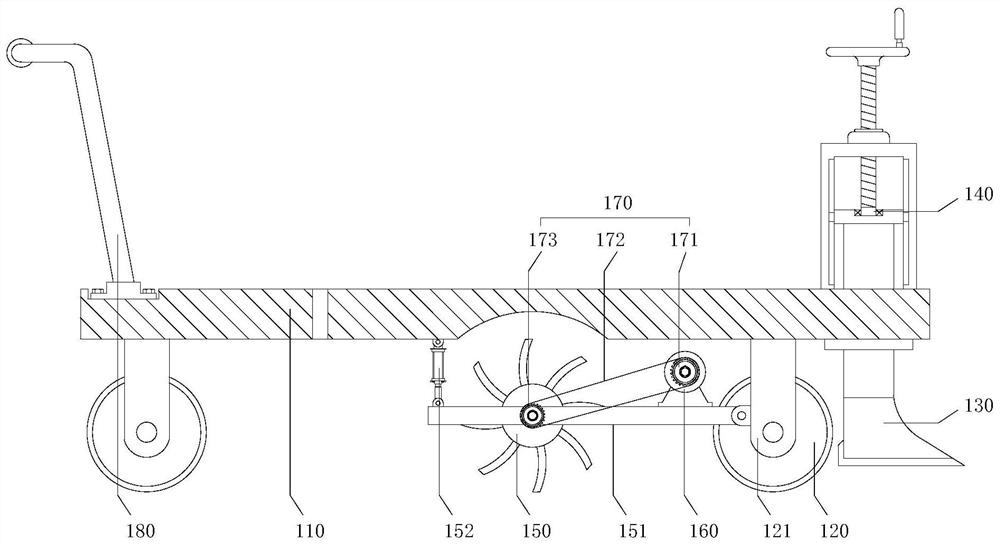

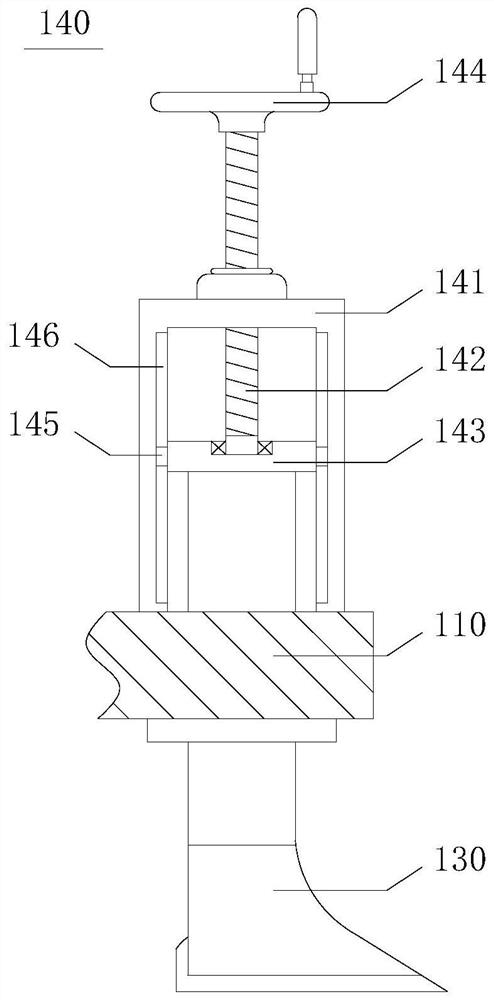

[0034] see figure 2 The soil-turning mechanism 10 includes a base 110, a height adjustment member 140, a crushing roller 150, and a first motor 160. The four corners of the bottom of the base 110 are equipped with rollers 120 through support legs 121, and the convenient movement of the soil-turning mechanism 10 is realized by using the rollers 120. The height adjustment member 140 is fixedly connected to one end of the top of the base 110, and several sets of plowshares 130 are uniformly arranged on the bottom of the height adjustment member 140, and the height of the plowshares 130 is synchronously adjusted through the height adjustment member 140 to control the turning depth of the soil, crush the soil The roller 150 is rotatably connected to the support leg 121 through the swing arm ...

Embodiment 2

[0040] see Figure 1-6 , the present invention provides a technical solution: a soil pollution control device, including a soil turning mechanism 10 and a mixing and spraying mechanism 20 .

[0041] see figure 2 The soil-turning mechanism 10 includes a base 110, a height adjustment member 140, a crushing roller 150, and a first motor 160. The four corners of the bottom of the base 110 are equipped with rollers 120 through support legs 121, and the convenient movement of the soil-turning mechanism 10 is realized by using the rollers 120. The height adjustment member 140 is fixedly connected to one end of the top of the base 110, and several sets of plowshares 130 are uniformly arranged on the bottom of the height adjustment member 140, and the height of the plowshares 130 is synchronously adjusted through the height adjustment member 140 to control the turning depth of the soil, crush the soil The roller 150 is rotatably connected to the support leg 121 through the swing arm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com