Method for moulding sheet into component of complex shape having areas with different mechanical properties

A technology of complex shapes and sheets, which is applied in the field of molding sheets into complex shapes of parts with different properties and regions, can solve problems such as ineffectiveness and heavy furnace lines, and achieve light weight and economical production of finished parts. light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

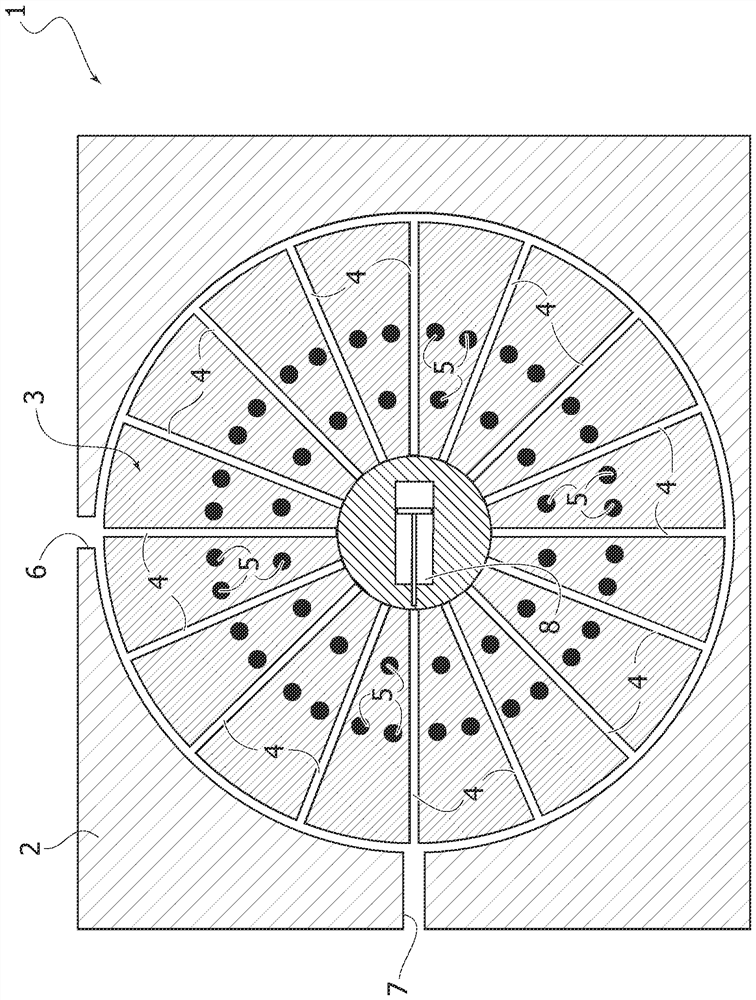

[0031] In the following description, various specific details are illustrated in order to provide a thorough understanding of examples of one or more embodiments. Embodiments can be practiced without one or more of the specific details, or with other methods, components, materials, etc. In other instances, known structures, materials, or operations are not shown or described in detail to avoid obscuring aspects of the embodiments. In the context of the present description, reference to "an embodiment" indicates that a particular configuration, structure, or characteristic described with respect to the embodiment is included in at least one embodiment. Thus, phrases such as "in an embodiment," which may appear in different places in this description, are not necessarily referring to the same embodiment. Furthermore, particular configurations, structures, or characteristics may be combined in suitable manners in one or more embodiments and / or may be associated with the embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com