Manufacturing method of laser printing aluminum-plated foil

A production method and a technology of aluminum foil, applied in printing, printing devices, inks, etc., can solve the problems of low registration accuracy, low production efficiency, low input-output rate, and large shear force, and achieve flexible processing methods, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

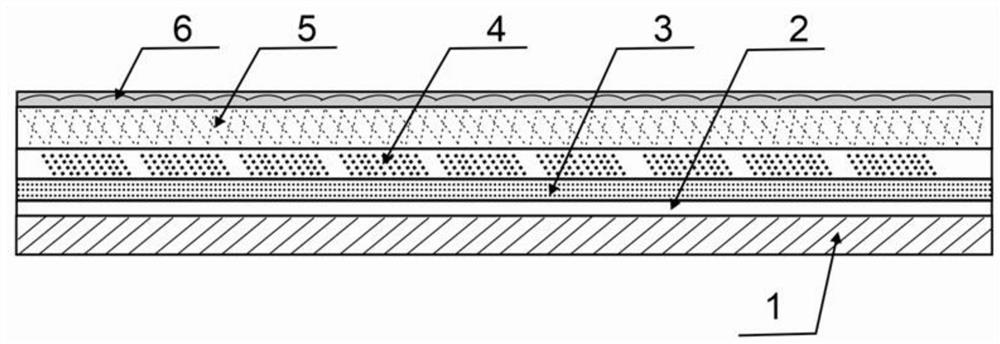

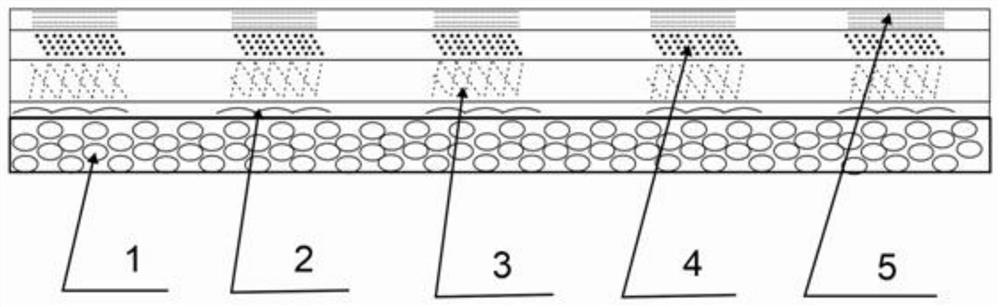

[0049] Example 1: as Figure 1-2 As shown in the figure, a color aluminum foil structure and a hot stamping method thereof are as follows: according to the customer's needs, the customer's design pattern is printed on the base film layer with temperature-resistant ink, and then in-line laser embossing is carried out to obtain a laser effect, and then sent into the The vacuum aluminum plating equipment performs aluminum plating processing to obtain laser anodized aluminum foil with color graphics, and then transfers it to the printed product through the cursor positioning and hot stamping to obtain the final product. The method includes the following steps:

[0050] Step 1. Color graphic design and processing: According to the customer's customized needs, design the pictures or LOGO that the customer needs to focus on on the outer packaging as a single-print graphic and typesetting according to the production and machine specifications;

[0051] Color pictures are mainly CMYK ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com