External thread rolling equipment and thread rolling method using same

An external thread and equipment technology, applied in the field of external thread rolling equipment, can solve the problems of increasing device cost, wasting processing time, reducing processing efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

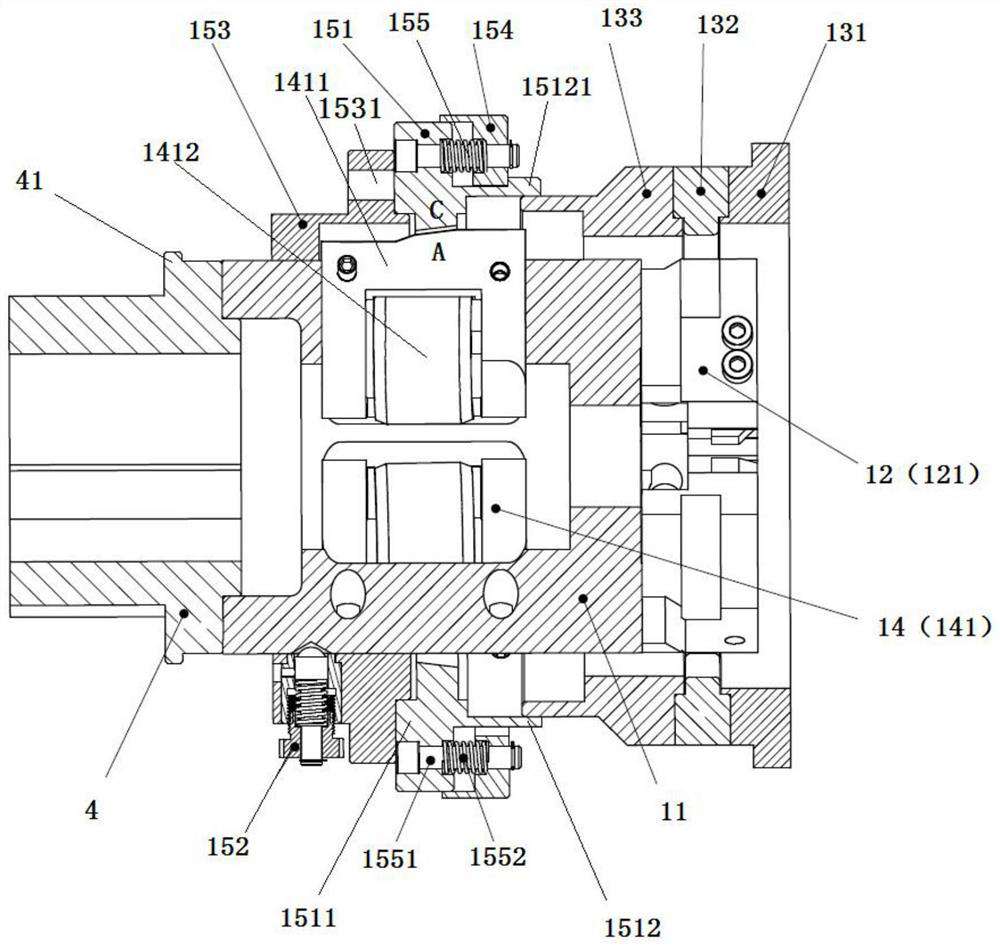

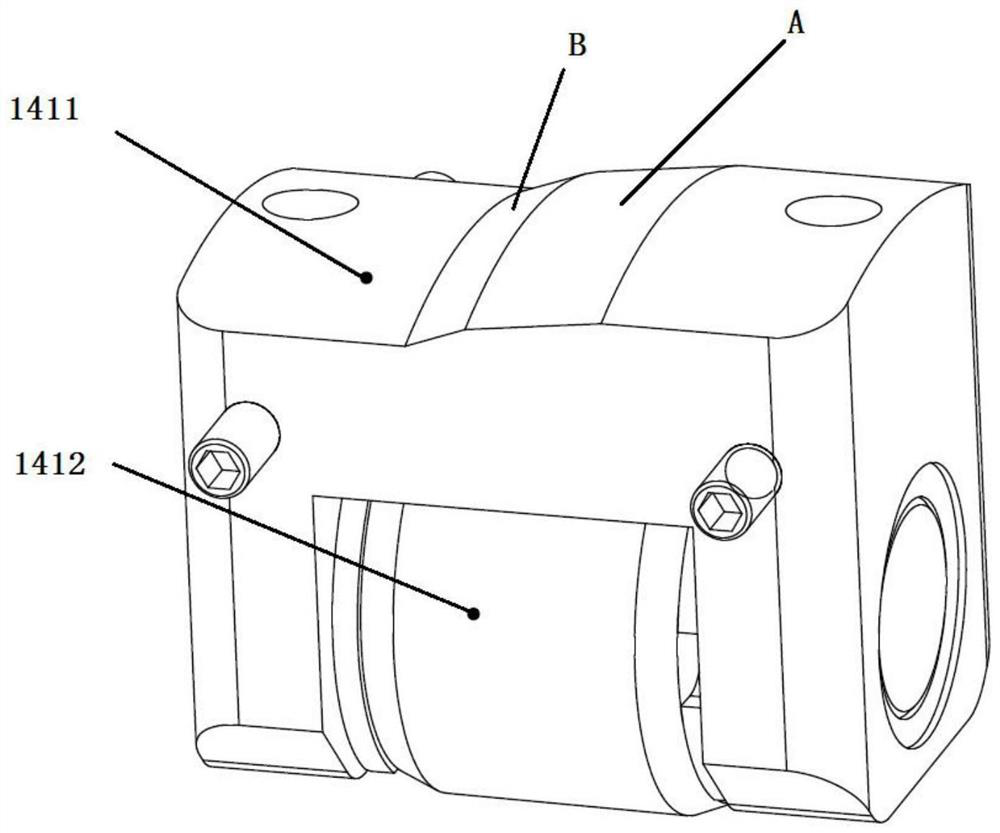

[0069] Different from the above-mentioned embodiments, such as Figure 5 As shown, the inner surface of the expansion wheel ring 151 is rotationally symmetrical with three smooth inclined surfaces C, and the number of the smooth inclined surfaces C is the same as the number of the thread rolling wheel assembly 141 or the number of the smooth inclined surfaces C is an integer multiple of the number of thread rolling wheel assemblies 141 . In the axial direction of the expansion ring 151, the smooth inclined surface C is in any cross-section of the expansion ring 151 except that the taper slope corresponds to the taper slope of the first tapered surface A. (The plane perpendicular to the axis of the expansion ring 151, that is, the radial section of the expansion ring 151), the distance from the smooth inclined surface C to the axis of the expansion ring 151 gradually decreases. By rotating the expanding wheel ring 151, the smooth inclined surface C forces the first tapered sur...

Embodiment 3

[0075] Different from the above-mentioned embodiments, three elastic limit threaded holes are provided on the side wall of the expanding wheel sliding sleeve 153 in a rotational symmetry, and the axes of the elastic limiting threaded holes are arranged along the radial direction of the expanding wheel sliding sleeve 153 , the adjusting nut 1522 of the elastic limit assembly 152 is screwed into the threaded hole of the elastic limit. Correspondingly, three conical pre-compression grooves 111 are provided on the outer surface of the frame body 11 to form a group of conical pre-compression grooves.

[0076] As a preference, along the axial direction of the frame body 11, a plurality of the conical precompression groove groups may be provided, and all the conical precompression grooves 111 cannot overlap when they are mapped to the same radial section. In an optimal state, it is preferable that no superimposition site exists. Furthermore, the position of the thread rolling housin...

Embodiment 4

[0078] Different from the above-mentioned embodiments, the knife expanding device 13 of the external thread rolling equipment is sleeved on the outside of the rib stripping device 12 , and includes a knife expanding end cover 131 , a knife expanding ring 132 and a knife expanding sliding sleeve 133 . The rib stripping device 12 includes a plurality of rib stripping knives 121 arranged on the frame body, a fourth compression spring radially compressed along the frame body 11 is arranged between the rib stripping knives 121 and the frame body 11, Corresponding to the rib stripping knife 121, the inner surface of the expansion knife ring 132 is rotationally symmetrical with a plurality of smooth curved surfaces. The distance from the axis of the expanding wheel ring decreases gradually, so that when the expanding knife ring 132 rotates relative to the expanding knife sliding sleeve 133, the distance from the rib stripping knife 121 to the axis of the frame body 11 gradually decrea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com