Grinding device for machining

A mechanical processing, No. 1 technology, applied in the direction of grinding drive devices, metal processing equipment, grinding machines, etc., can solve the problems of different grinding precision requirements, reduce yield, loss, etc., to improve processing efficiency and yield, reduce The effect of changing the position of the workpiece and reducing the probability of damage to the surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

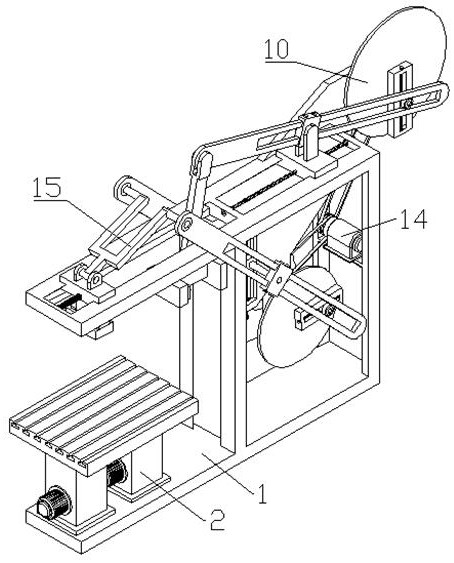

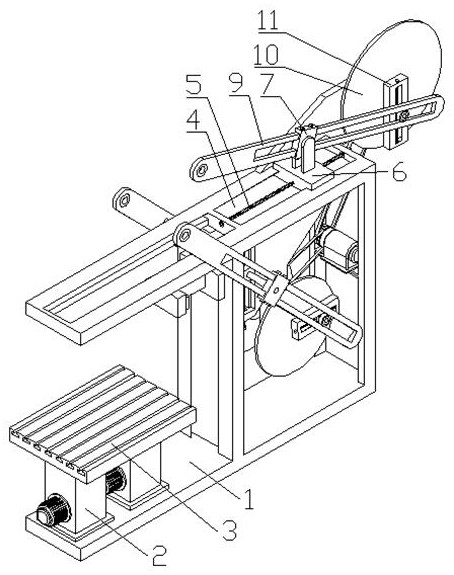

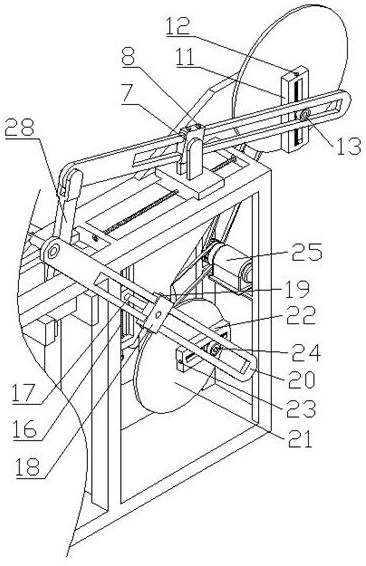

[0016] Such as Figure 1-4 As shown, a grinding device for mechanical processing includes a main body 1, a push rod motor 2, a workbench 3, a No. 1 dovetail groove 4, a No. 1 adjusting screw 5, a No. 1 support slider 6, and a No. 1 fastening slider 7 , No. 1 fastening bolt 8, No. 1 transmission frame 9, upper adjustment disc 10, upper adjustment seat 11, upper adjustment screw rod 12, upper adjustment sliding seat 13, transmission part 14, grinding part 15, the front part of the main body 1 is fixed There are two vertical push rod motors 2, and a horizontal workbench 3 is fixed on the top of the push rods of the two push rod motors 2, and a horizontal No. 1 dovetail groove 4 is opened on the rear upper part of the main body 1. The rear upper part is rotatably connected with a horizontal No. 1 adjusting screw 5 through a bearing, and the rear ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap