An automatic press-fitting process for a draft tube

A diversion tube and automatic technology, which is applied in the field of the automatic press-fitting process of the diversion tube, can solve the problems of low degree of automation, slow press-fitting speed, inconvenient operation, etc., and achieves a high degree of automation, fast press-fitting speed and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The following description and drawings sufficiently illustrate specific embodiments of the invention to enable those skilled in the art to practice them. Other embodiments may include structural, logical, electrical, process, and other changes. The examples represent only possible variations. Unless expressly required, individual components and functions are optional and the order of operations may vary. Portions and features of some embodiments may be included in or substituted for those of other embodiments. The scope of embodiments of the invention includes the full scope of the claims, along with all available equivalents of the claims.

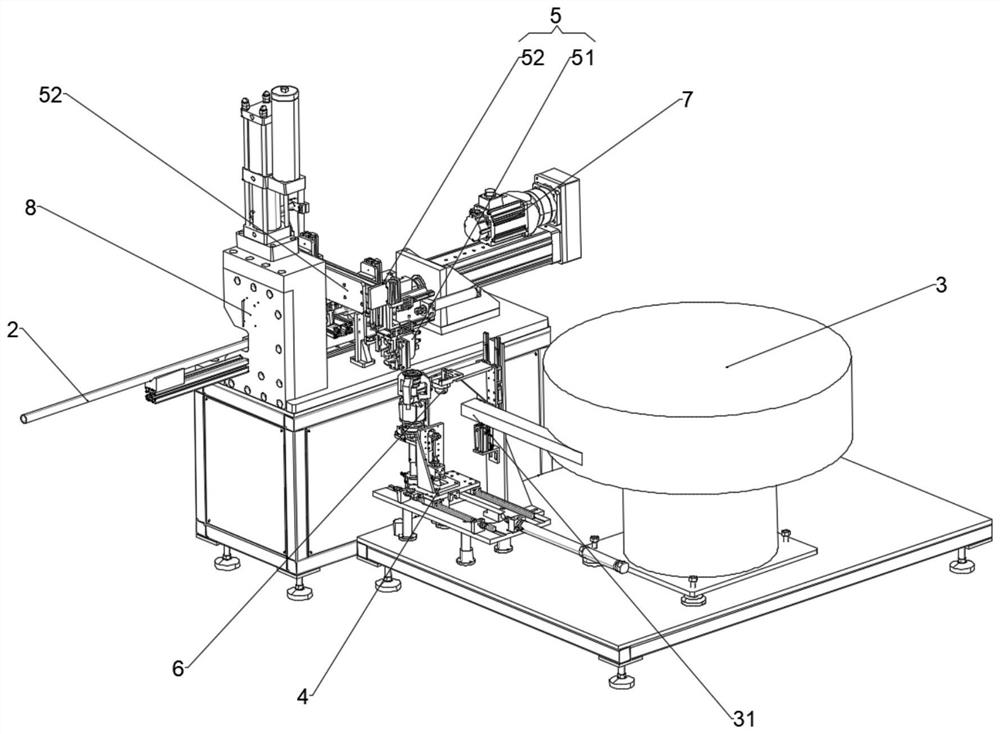

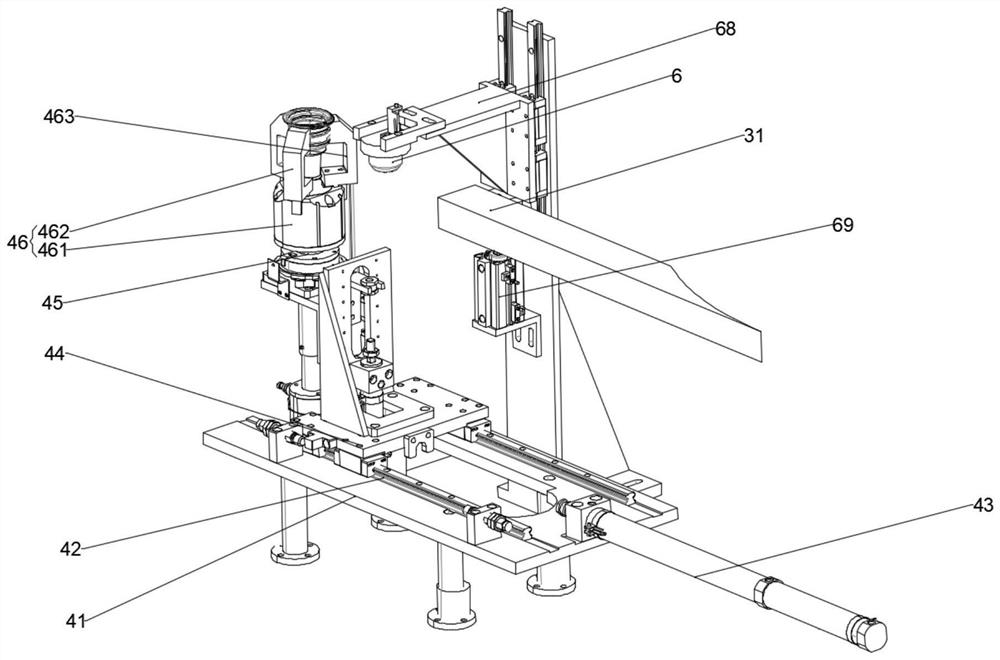

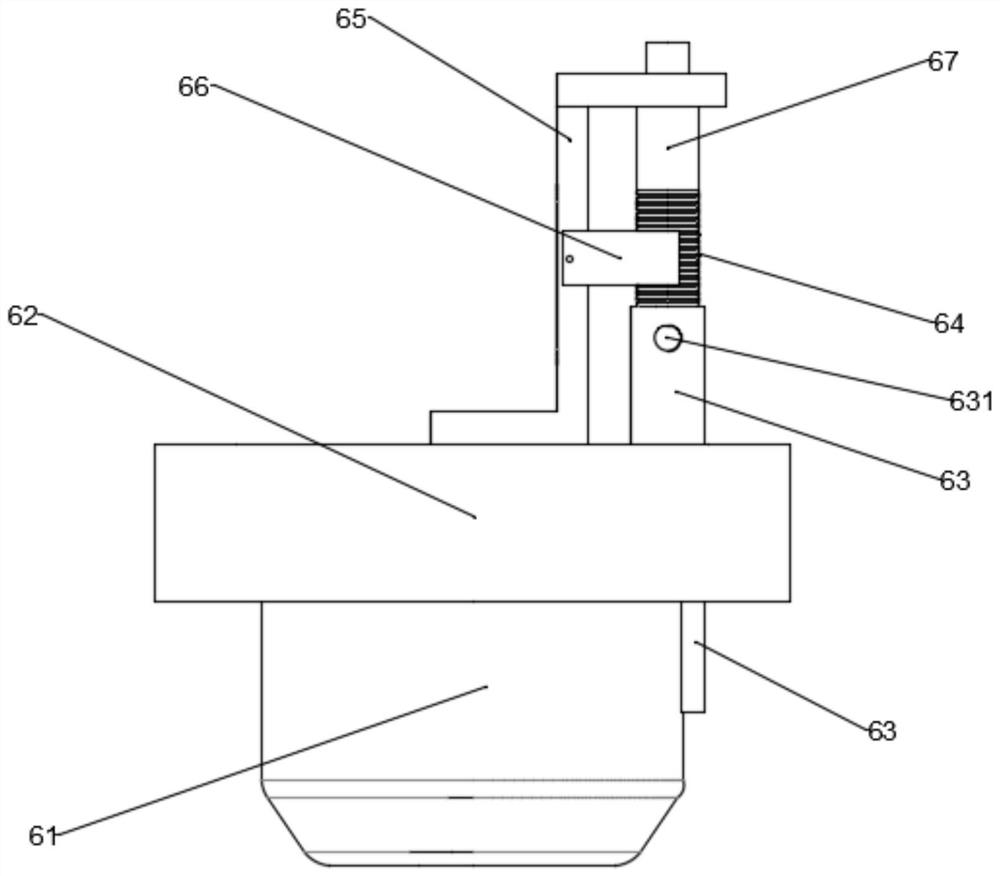

[0043] like Figure 1-8 As shown, an automatic press-fitting process for a guide tube,

[0044] It includes: a diversion joint 1 and a pipe body 2, the diversion joint 1 is provided with a thread 11, and the pipe body 2 is provided with a positioning air hole 21, which is characterized in that it sequentially includes the follo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com