Crane operation monitoring system with intelligent video function

A technology of operation monitoring and safety monitoring system, applied in the directions of transportation and packaging, load hanging components, safety devices, etc., can solve the hidden dangers of equipment and buildings, and the drivers cannot pay attention and judge at the same time, which brings many problems, etc. problem, to achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0091] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0092] The invention provides a crane operation monitoring system.

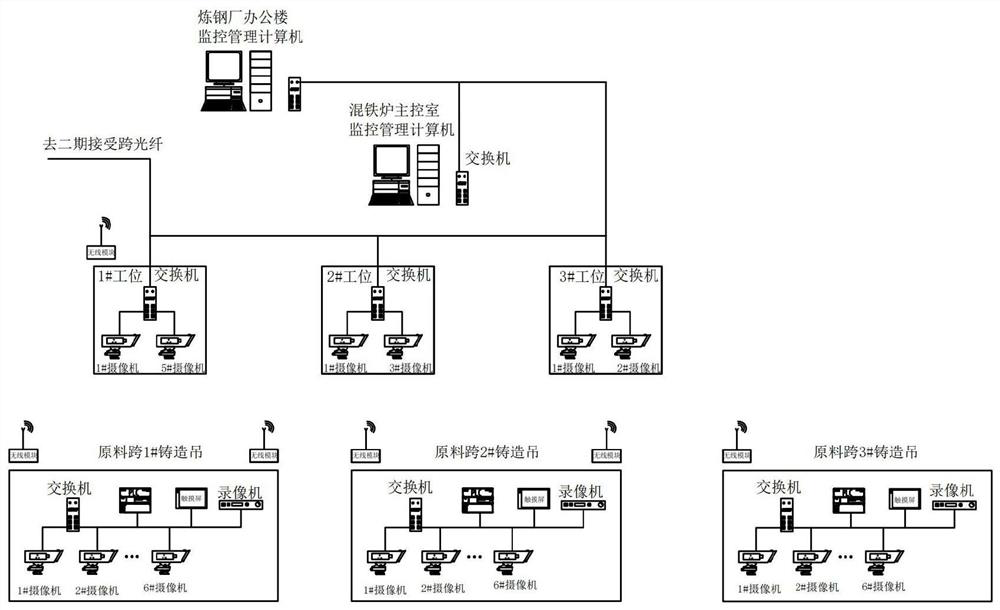

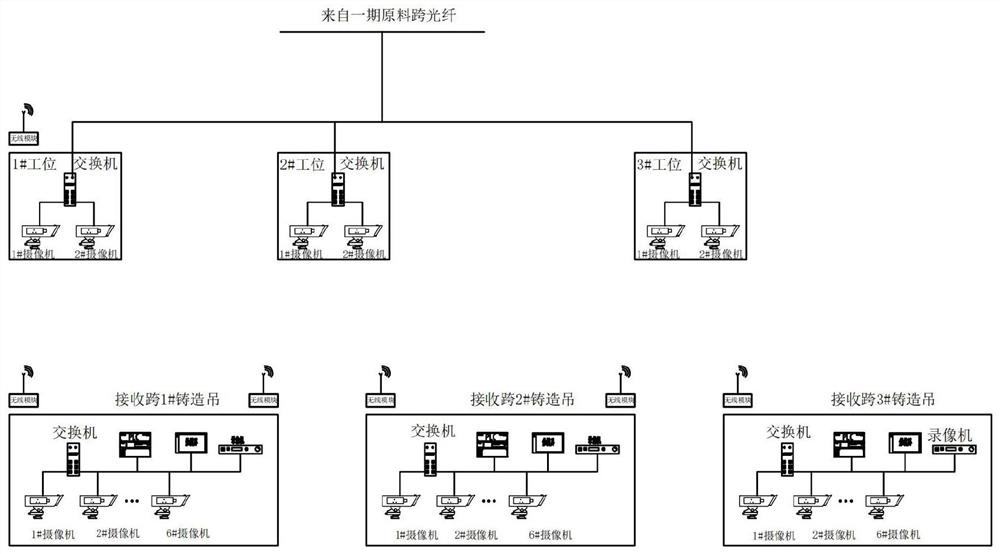

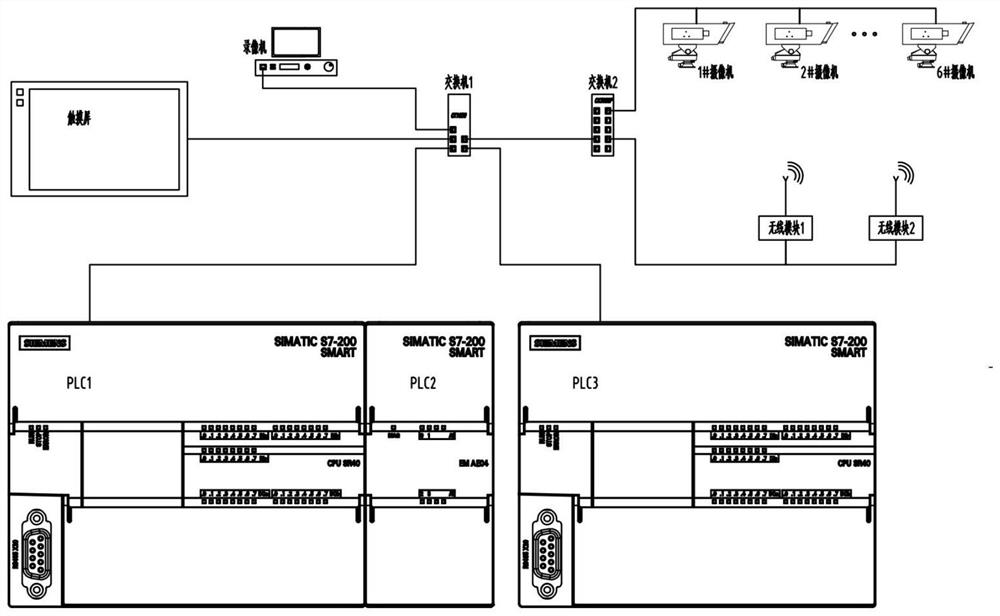

[0093] Please refer to Figure 1 to Figure 56, in the crane operation monitoring system of the present invention, the crane operation monitoring system includes: crane equipment 1, ground floor, multiple cameras 9, hard disk video recorder, wireless communication module, display, HD-CMS safety monitoring equipment, safety monitoring system Host and ground video service host, multiple cameras 9 are all set on the crane equipment 1;

[0094] A plurality of cameras 9 are respectively arranged on the ground floor and the crane equipment 1, the camera configuration on the ground floor: each lifting station is equipped with two cameras, twelve stations, a total of twenty-four cameras, and the camera 9 on the crane 1 is arranged : In order to monitor the left and right directions of the car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com