Automatic road embossing machine

An automatic and engraving technology, which is applied in the direction of engine components, engine lubrication, roads, etc., can solve the problems of unsatisfactory work efficiency, increase the difficulty of workers' operation, and hard work in the process of use, so as to prevent smoke and dust from spreading, improve cutting efficiency, Easy to control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the specific embodiments in the accompanying drawings.

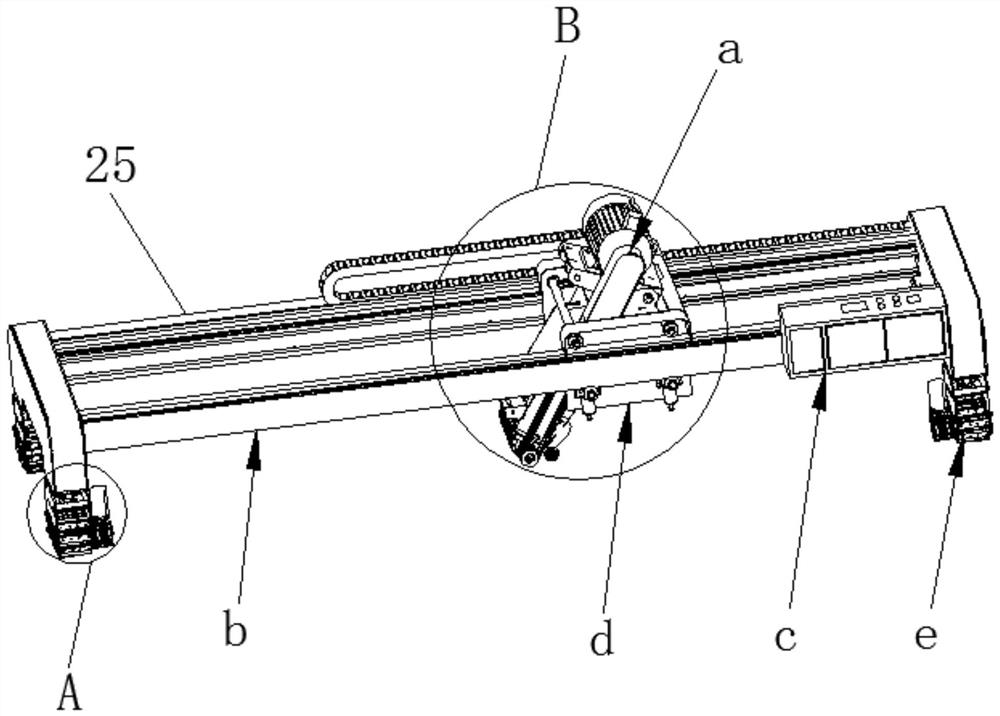

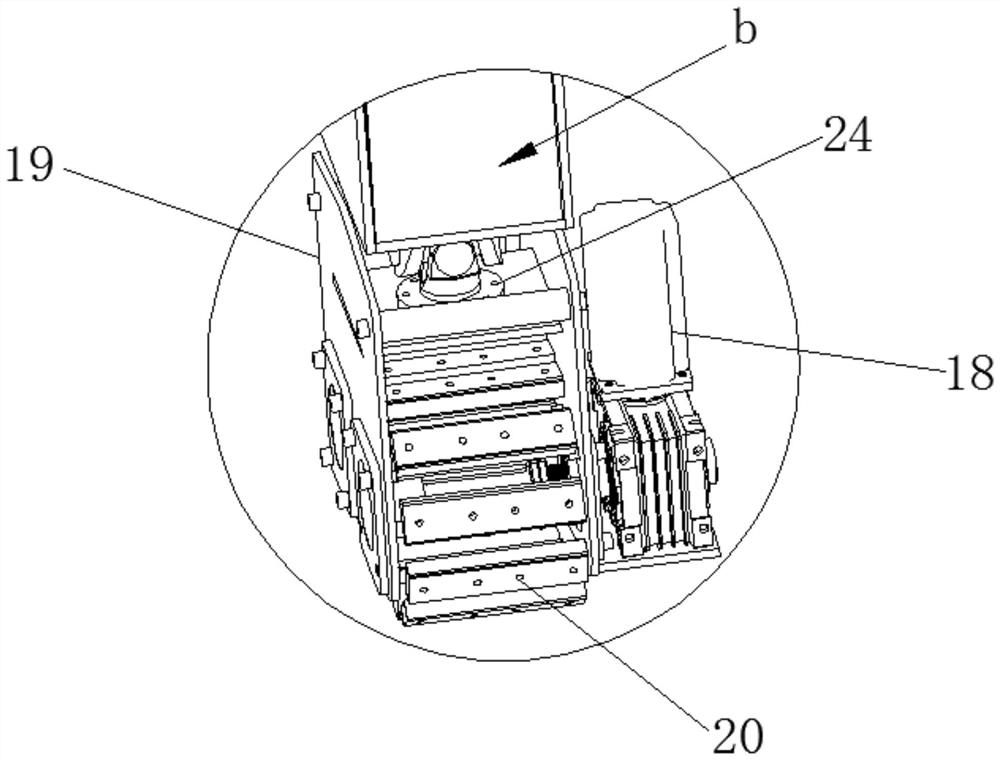

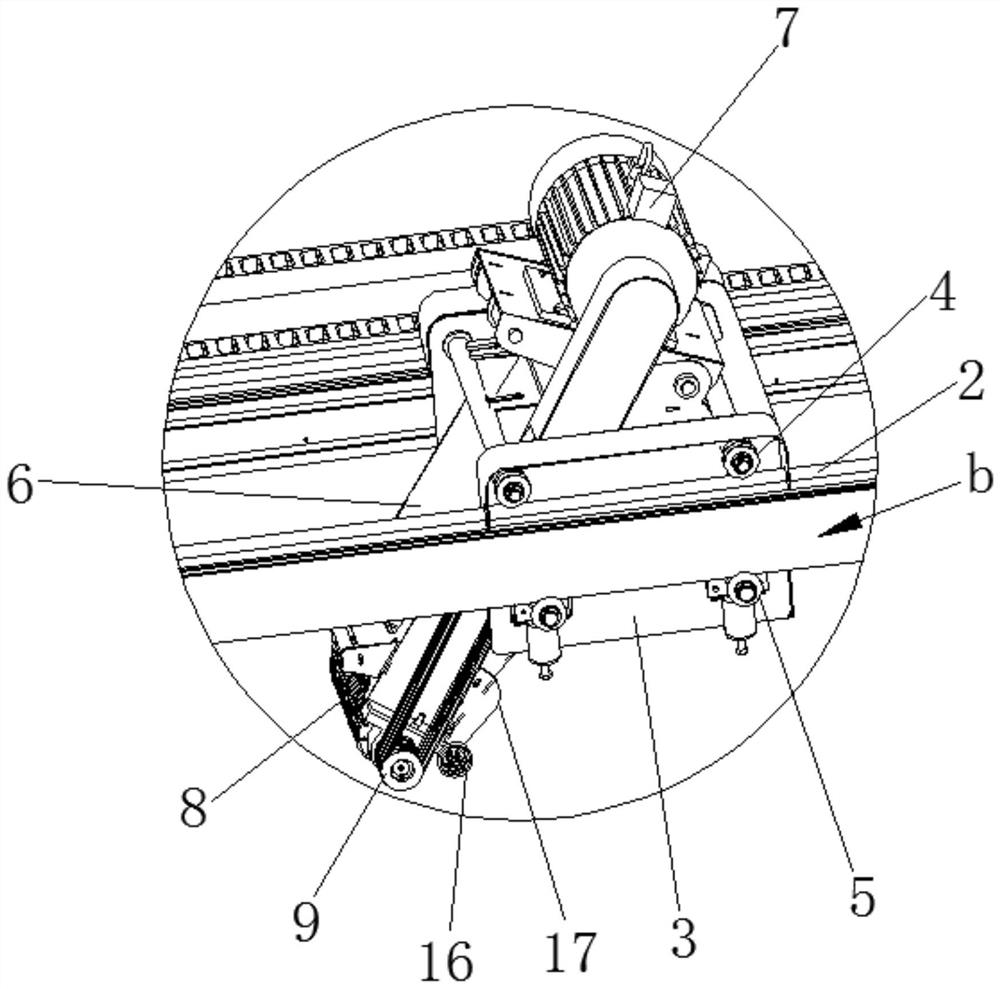

[0027] refer to Figure 1-6 , a road automatic engraving machine of the present invention, including a cutting machine a, also includes an outer frame support b and a controller c, the outer frame support b is a U-shaped frame, a sliding seat d is slidably installed on the outer frame support b, and the sliding The seat d can slide linearly along the outer frame support b, and the first drive assembly that drives the sliding seat d to move horizontally is provided on the outer frame support b. The cutting machine a is rotatably installed on the sliding seat d, and the cutting machine a and the sliding seat d There is a second driving assembly that drives the cutting machine a to rotate, and a plurality of moving seats e are provided at the bottom of the outer frame support b to drive the outer frame support b to move, wherein the cutting mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com