Sealing lock plate assembly and plate installation structure thereof

A technology for installing structures and locking plates, which is applied in the field of building decoration materials, can solve problems such as increased labor costs and material costs, damage, and plate damage, and achieves the goal of avoiding mutual extrusion damage, avoiding mutual excessive extrusion, and reasonable structural design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

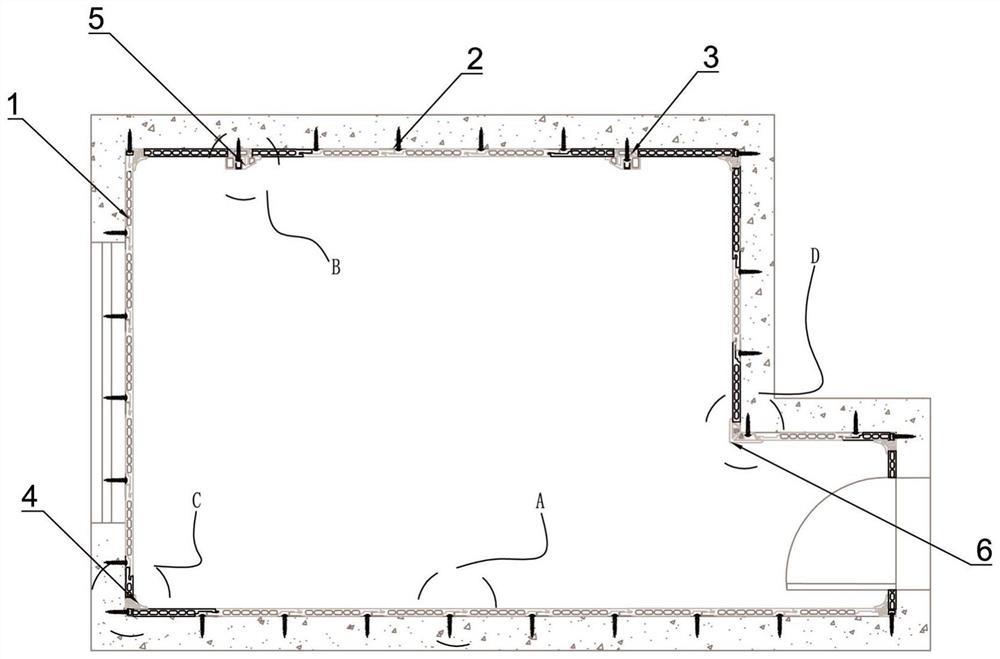

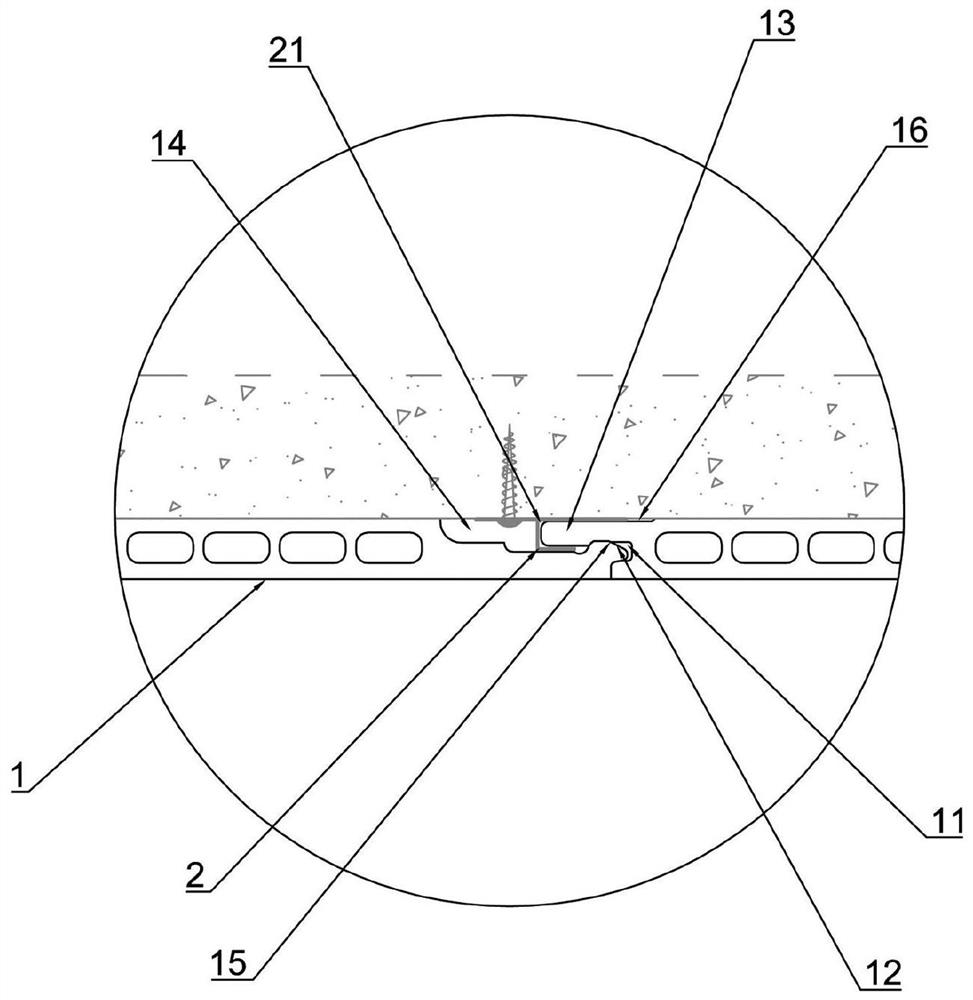

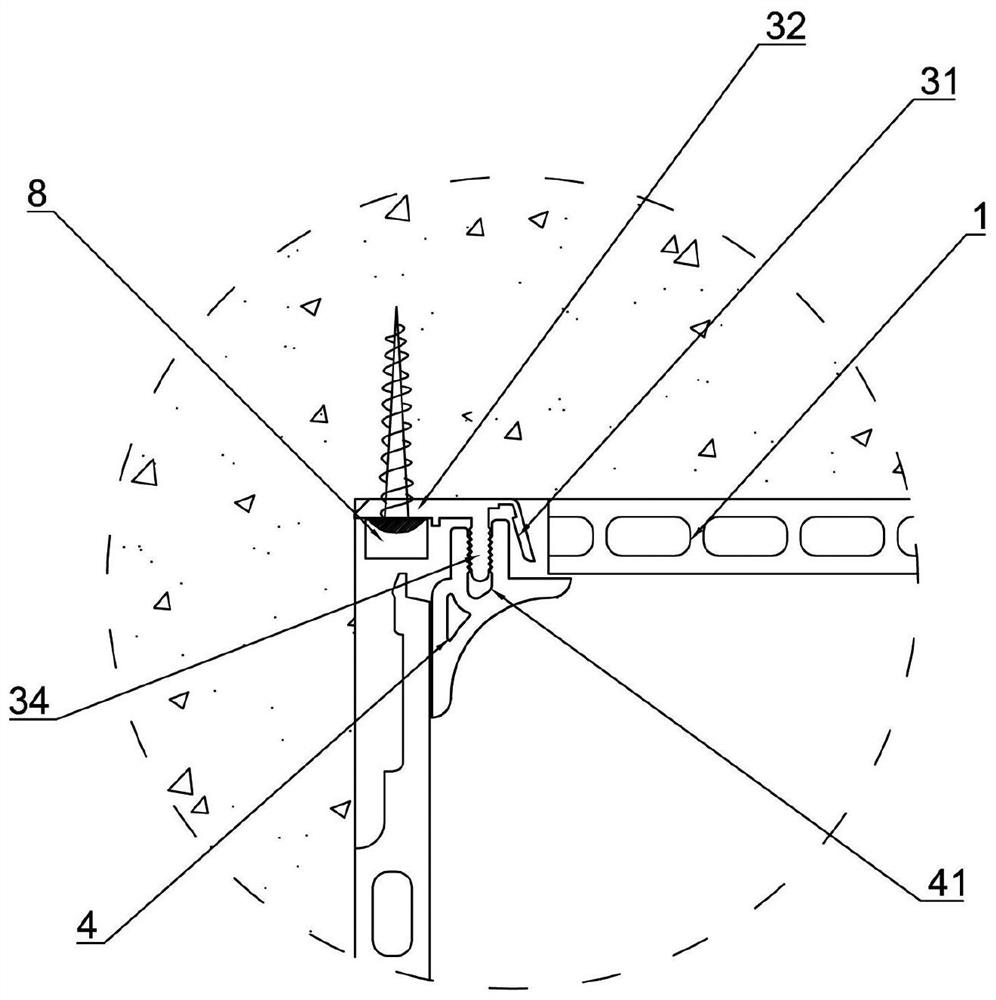

[0028] In the above scheme, the male corner line is L-shaped, and the inner surface of the male corner line is provided with a male corner wire installation piece in the middle of the inner surface of the male corner line. Both the surface and the external corner line are provided with zigzag stripes according to the inner surface of the slot.

[0029] When installing at the corner of the wall, the telescopic piece can be installed in the corner in advance, and fixed on the corner through the fast-tooth self-tapping screw through the installation part. The male corner line installer is inserted in the male corner line press slot of the telescopic part. Its installation is extremely convenient and quick, and it is high-grade and beautiful. At the same time, it also prevents the corners from being too sharp, which may cause children to be accidentally bumped and injured.

Embodiment 2

[0031] In the above scheme, the inner corner line is L-shaped strip, the inner corner line is provided with a corner line pressing slot in the middle of the inner surface of the inner corner line, and the inner corner line installation piece is inserted in the inner corner line pressing slot, and the inner corner line installation piece The outer surface and the internal angle line are provided with zigzag stripes according to the inner surface of the slot.

[0032] When installing in the corner, the telescopic piece can be installed in the corner in advance, and fixed on the corner through the fast-tooth self-tapping screw through the installation part. The slot is inserted on the internal angle line installation piece of the telescopic element to complete the installation of the internal angle line.

Embodiment 3

[0034] In the above scheme, the outer surface of the decorative wire part is provided with an inwardly recessed decorative groove, and the self-tapping screw located in the decorative groove penetrates the installation part of the telescopic part and fixes the decorative wire part and the telescopic part on the wall , the decorative strip is inserted into the decorative groove.

[0035] The decorative wire parts are installed on the wall through the quick-tooth self-tapping screws through the telescopic parts. The decorative strips can be selected according to customer needs. The decorative strips can be placed in the decorative grooves, which is extremely convenient and fast, and can block the self-tapping screws to avoid exposed. There are elastic pressing pieces on both sides of the telescopic parts used to install the decorative line parts. The elastic pressing pieces can ensure that the mutual force between the locking plates will not be too large, and at the same time, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com