Large-opening blind hinge

A concealed hinge and large opening technology, applied in the field of concealed hinges, can solve the problems that the door leaf 1 cannot meet the design requirements, processing or assembly errors, etc., and achieve the effects of good user experience, reduced defective rate, and improved scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

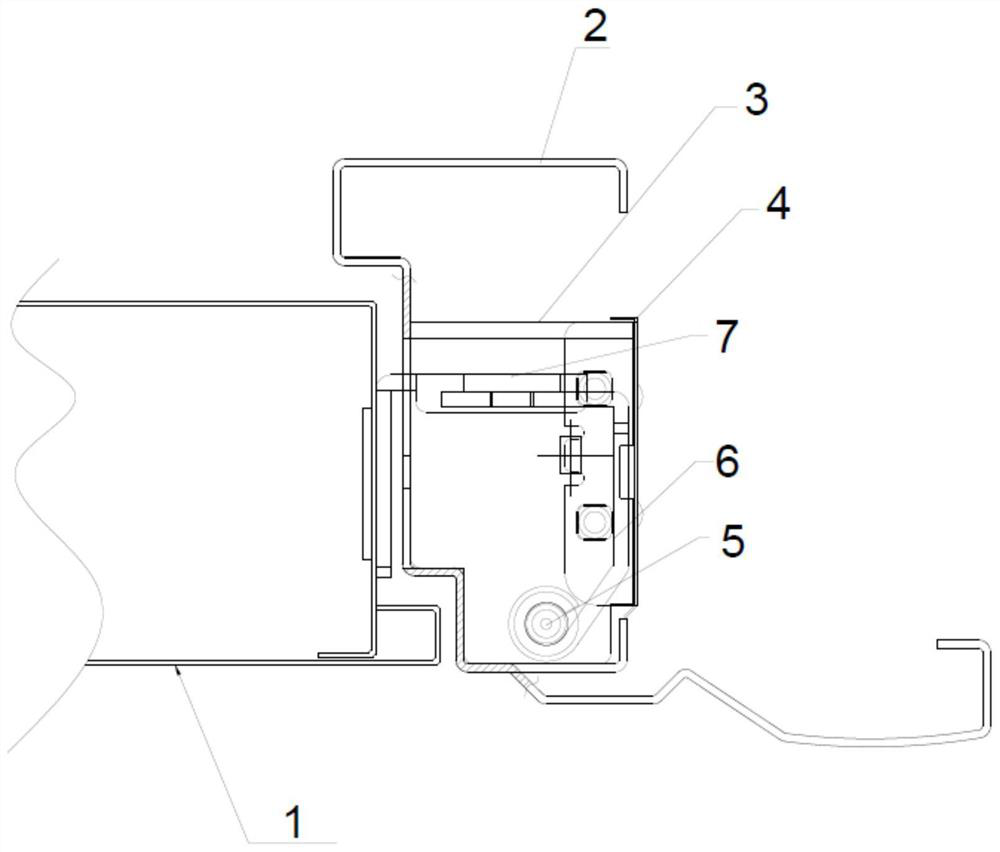

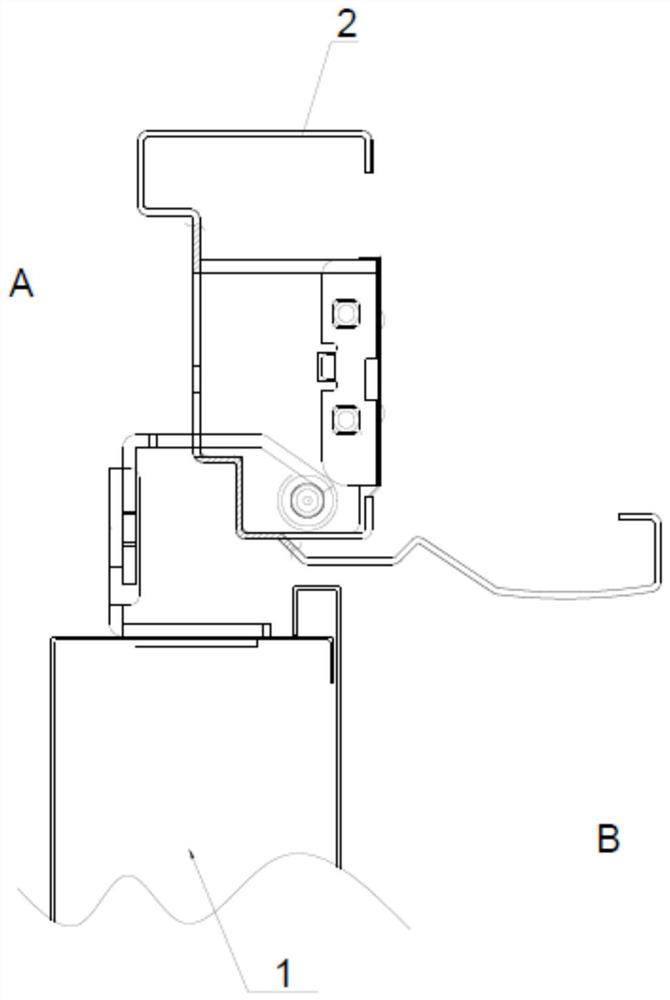

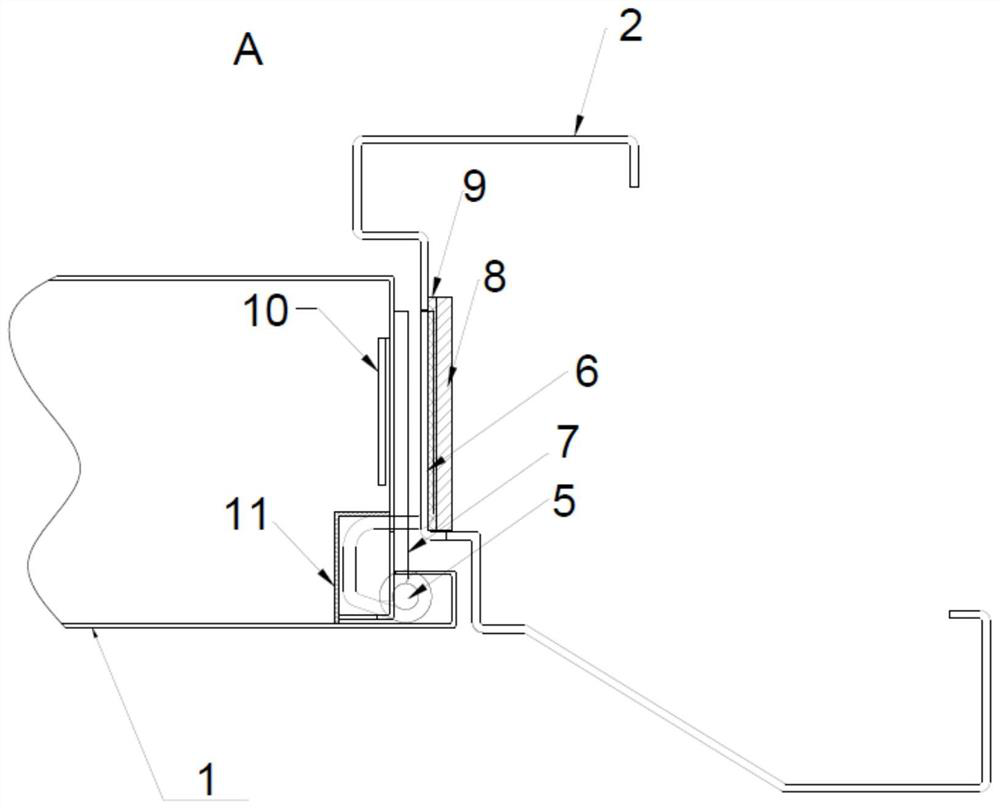

[0033] see Figure 3 ~ Figure 7 In Embodiment 1 of the present invention, a concealed hinge with a large opening is provided, which is suitable for the hinge connection between the door leaf 1 and the door frame 2. The concealed hinge with a large opening includes a concealed hinge frame 6, a concealed hinge leaf 7 and a concealed hinge pin 5. The hinge frame 6 is rotatably connected with the concealed hinge fan 7 through the concealed hinge pin 5 .

[0034] The concealed hinge frame 6 includes an installation section and a bending section that allows the turning space for the seam edge of the door leaf 1 during the rotation of the door leaf 1 relative to the door frame 2, and the bending section is an L-shaped bending section.

[0035] refer to image 3 , when the door leaf 1 is closed, the bending section is located inside the door leaf 1, and the concealed hinge leaf 7 is provided with a through hole that allows the bending section to pass through, and the door leaf 1 is p...

Embodiment 2

[0041] The difference from Embodiment 1 is that the outer surface of the door leaf 2 is rolled with a first threaded hole, the concealed hinge leaf 7 is connected with the first threaded hole through a first bolt, the outer surface of the door frame 2 is rolled with a second threaded hole, and the installation section Connect with the second threaded hole through the second bolt.

[0042] Compared with the first embodiment, the installation method of the second embodiment reduces the door frame hinge connecting plate 8 , the hinge gasket 9 and the door leaf hinge connecting plate 10 , which further reduces the production cost and improves the assembly efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com