A multi-angle automatic test tool for product vacuum

An automatic testing, multi-angle technology, applied in the direction of vehicle testing, machine/structural component testing, measuring devices, etc., can solve problems such as difficult operation, efficiency impact of workpiece detection, inability to hold different workpieces, etc., to achieve structural Scientific and reasonable, improve detection efficiency and simplify operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

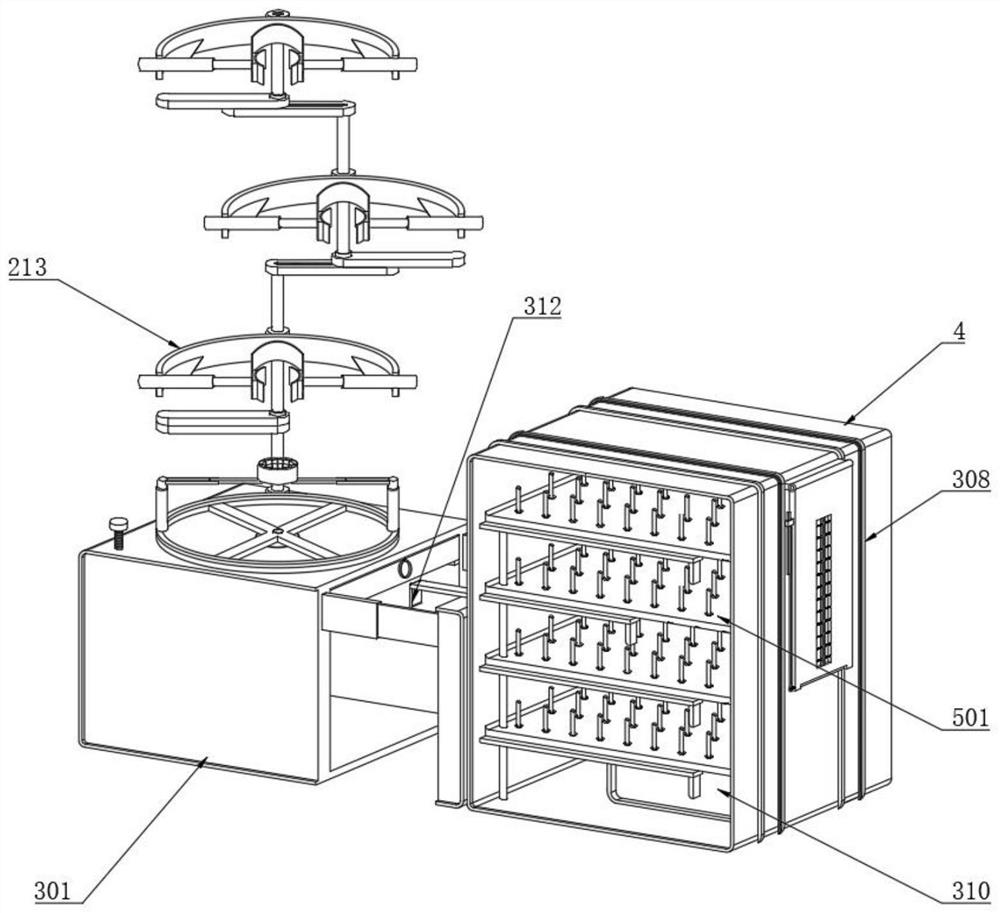

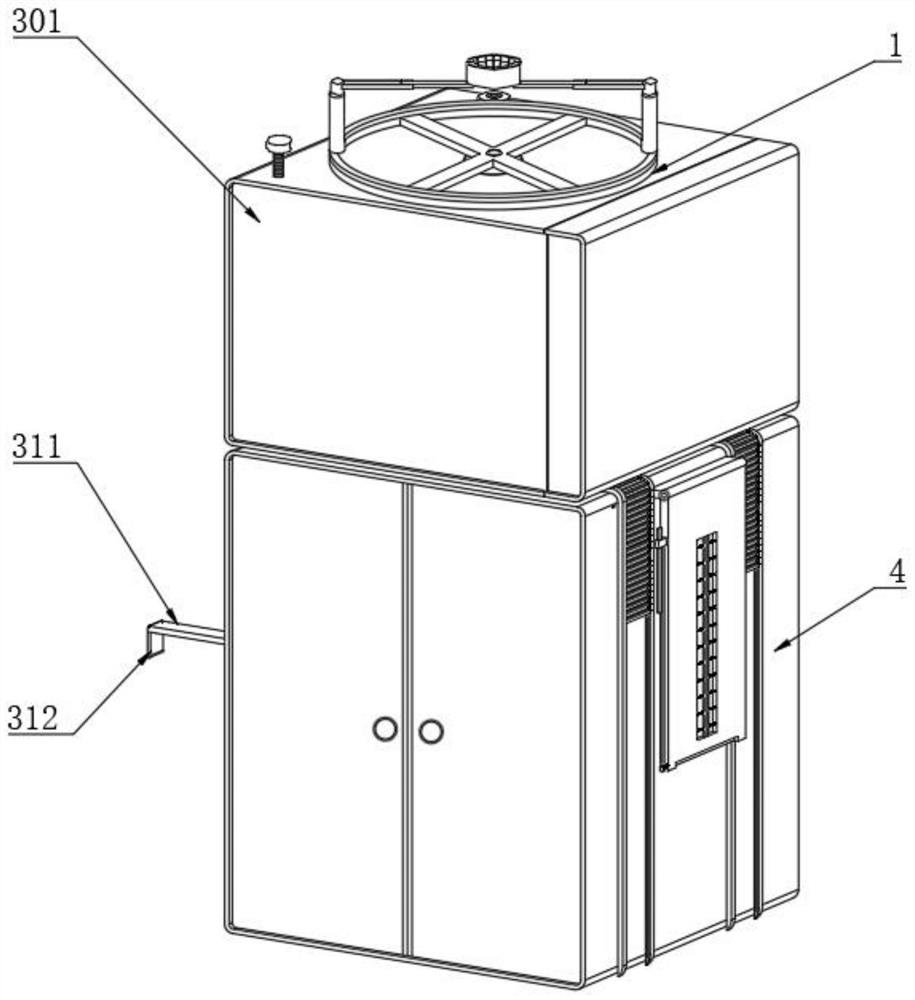

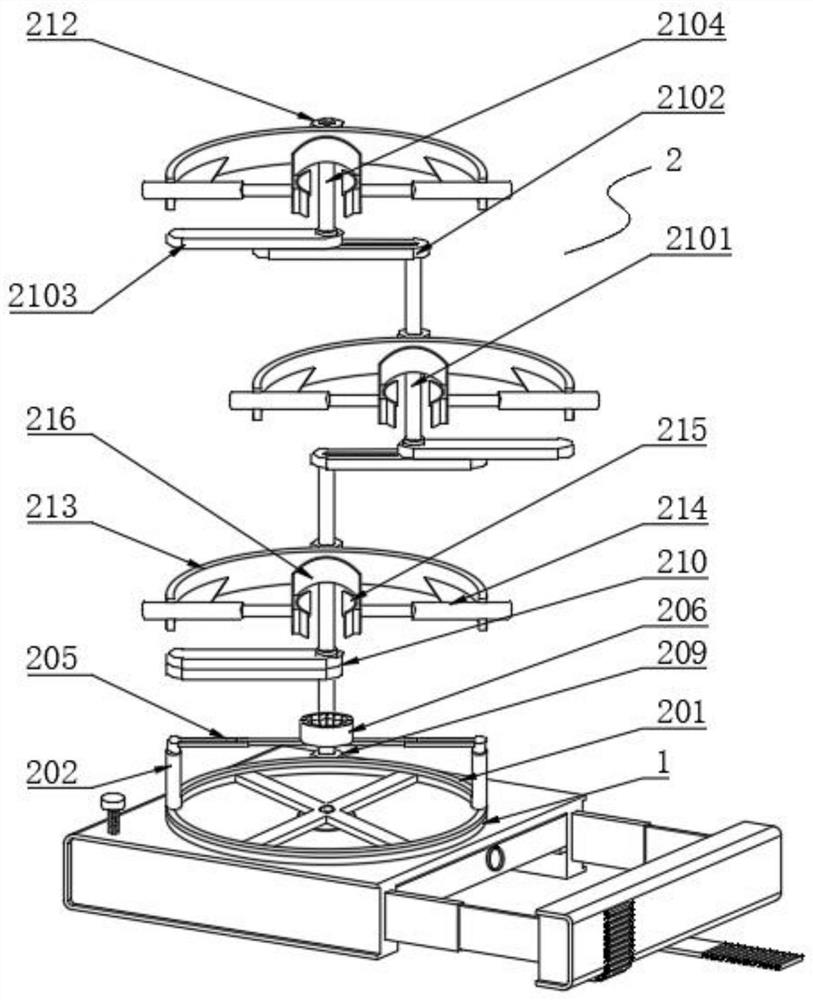

[0050] Example: such as Figure 1-12 As shown, the present invention provides a multi-angle automatic test tooling technical solution for product vacuum, including a rotating disk 1, a test clamping assembly 2 is installed on the top of the rotating disk 1, and the testing clamping assembly 2 includes a rotating ring 201, a positioning tube 202, Support spring 203, sliding block 204, horizontal pull rod 205, support cup 206, slant plate 207, extrusion spring 208, first inner coil 209, adjustment frame 210, folding ring 211, second inner coil 212, arc Plate 213, fixed electric push rod 214, special-shaped clamping block 215 and connecting belt 216;

[0051] The rotating ring 201 is rotatably mounted on the top surface of the rotating disk 1, and both ends of the rotating ring 201 are welded with a positioning tube 202, and the inside of the positioning tube 202 is slidably connected to a sliding block 204 through a supporting spring 203, and the top of the sliding block 204 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com