Wavelength tunable laser generation method based on perovskite thin film

A production method and perovskite technology, applied in the field of lasers, can solve the problems of increased system cost, inability to achieve continuous adjustment of wavelength, laser system damage and pollution, etc., and achieve low cost, stable light output, good repeatability and The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

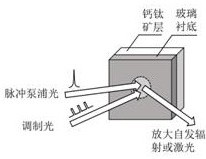

[0022] The present embodiment provides a method of generating a wavelength tunable laser generating method based on a perovskite film, mainly including the following steps:

[0023] 1, method of preparation of perovskite film.

[0024] The main component of the perovskite film is CH 3 NH 3 PB (i 0.5 BR 0.5 ) 3 It is prepared by spin coating. Specific steps are as follows:

[0025] 1 cleaning the glass substrate. Square glass having a side length of 15 mm was first put into glass cleaning agent, ethanol, acetone, and deionized water, for 15 minutes, respectively, after washing, was purged with flowing nitrogen.

[0026] 2 Preparation of precursor solution precursor solution in perovskite ore. Methyl iodide (CH) 3 NH 3 I), lead (PBI) 2 ), Methyl bromide (CH 3 NH 3 BR) and lead in bromide (PBBR 2 After blending with a molar ratio of 0.5: 0.5: 0.5: 0.5, the blend of N, N-dimethylformamide (DMF) and dimethyl sulfoxide (DMSO) was added. Solvent, stirred at room temperature for 12 hours,...

Embodiment approach 2

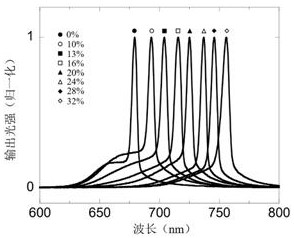

[0038] The present embodiment provides a method of generating a wavelength tunable laser generating method based on a perovskite film, mainly including the following steps:

[0039] 1, method of preparation of perovskite film.

[0040] The main component of the perovskite film is CH 3 NH 3 PB (i 0.78 BR 0.22 ) 3 It is prepared by spin coating.

[0041] 1 cleaning the glass substrate. Square glass having a side length of 15 mm was first put into glass cleaning agent, ethanol, acetone, and deionized water, for 15 minutes, respectively, after washing, was purged with flowing nitrogen.

[0042] 2 Preparation of precursor solution precursor solution inlate, methyl iodide (CH) 3 NH 3 I), lead (PBI) 2 ), Methyl bromide (CH 3 NH 3 BR) and lead in bromide (PBBR 2 After blending with a molar ratio of 0.78: 0.78: 0.22: 0.22, the blend of N, N-dimethylformamide (DMF) and dimethyl sulfoxide (DMSO) was added. Solvent, stirred at room temperature for 12 hours, prepared 1 mol / L of CH 3 NH 3 PB ...

Embodiment approach 3

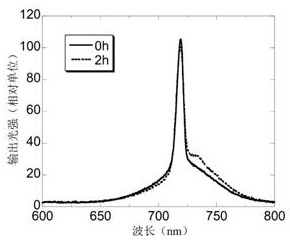

[0052] Selecting a quartz grating as a substrate, selecting any of the two embodiments described above, that is, a laser radiation output can be realized. The output laser peak half wave width is more narrow than amplifying the radiation, therefore has better monochrome.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap