An arc-shaped spillway waterproof material coating device

A technology of waterproof material and coating device, applied in the field of flood discharge, can solve the problems of insufficient and uniform waterproof material coating, unable to automatically move the coating equipment, etc., and achieve the effect of preventing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

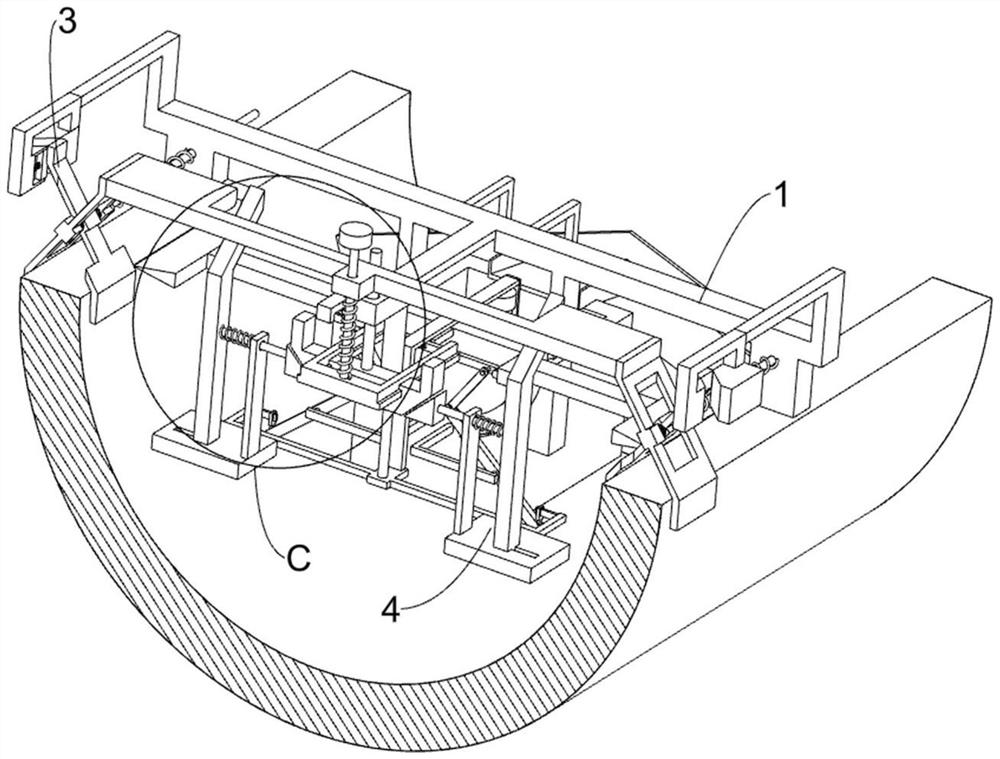

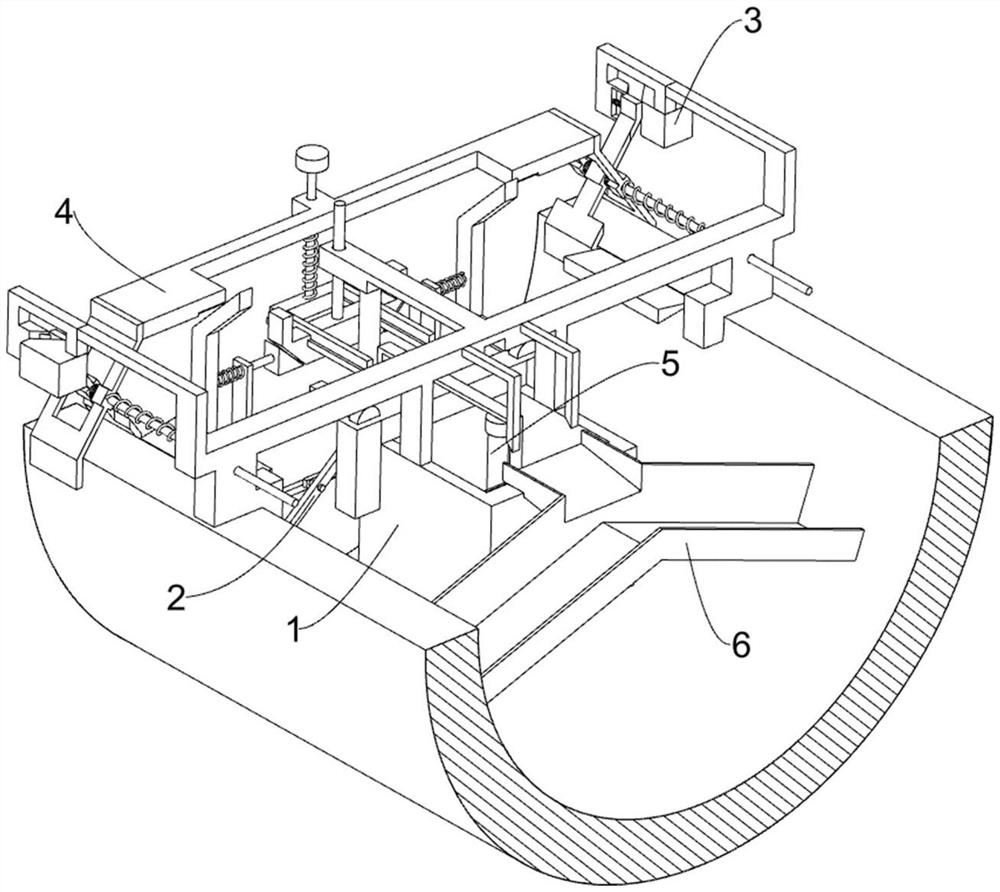

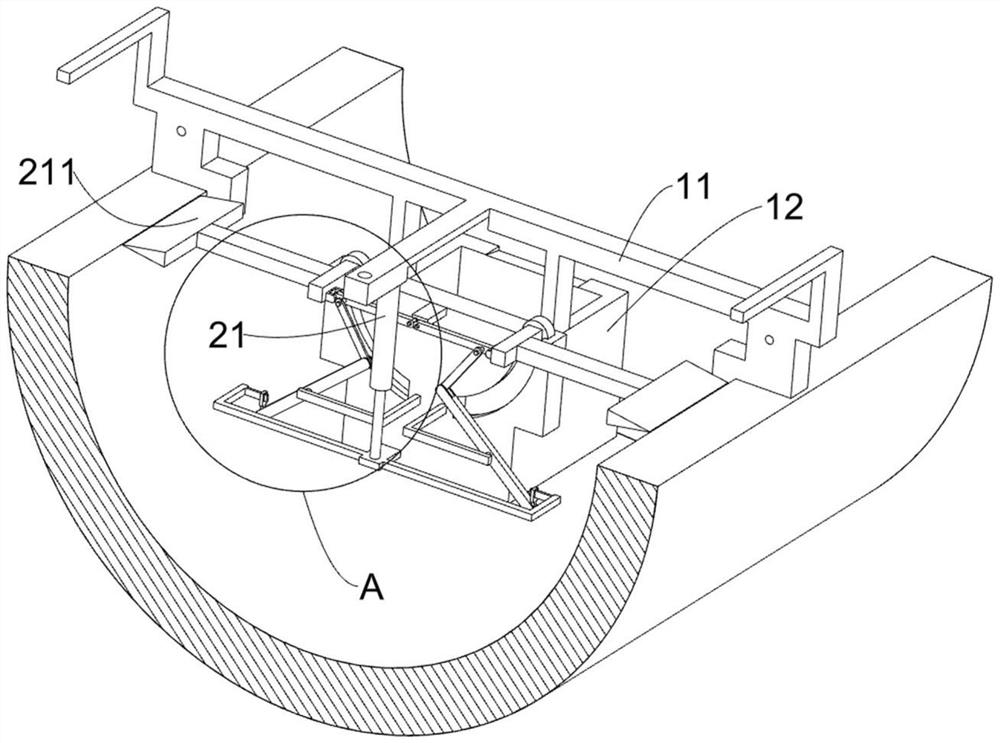

[0028] An arc-shaped spillway waterproof material coating device, such as Figure 1-10 As shown in the figure, it includes a sliding mechanism 1, a scraping mechanism 2, a clamping mechanism 3 and a pushing mechanism 4. The sliding mechanism 1 is set on the arc-shaped spillway, the scraping mechanism 2 is set on the sliding mechanism 1, and the scraping mechanism 2 is used for Scrape the waterproof material smeared on the inner wall of the arc-shaped spillway. The clamping mechanism 3 is provided on the sliding mechanism 1. The clamping mechanism 3 is used to fix the equipment for subsequent operations. The pushing mechanism 4 is provided on the clamping mechanism 3.

[0029] The sliding mechanism 1 includes a first sliding frame 11 and a first fixing frame 12. The first sliding frame 11 is slidably connected to the arc-shaped flood discharge top, and the first fixing frame 12 is connected to the first sliding frame 11. The first fixing frame 12 For installing waterproof mater...

Embodiment 2

[0038] On the basis of Example 1, as Figure 8 As shown, a stirring mechanism 5 is also included. The stirring mechanism 5 is arranged on the scraping mechanism 2. The stirring mechanism 5 is used for stirring the waterproof material in the first fixing frame 12. The stirring mechanism 5 includes a seventh fixing frame 51 and a screw 52. , stirring frame 53 and nut 54, the top of the first fixing frame 22 is connected with a seventh fixing frame 51, the seventh fixing frame 51 is in contact with the first fixing frame 12, the bottom of the seventh fixing frame 51 is connected with a screw 52, and the first fixing frame 12. The bottom is rotatably connected with a stirring frame 53. The stirring frame 53 is used to stir the waterproof material in the first fixing frame 12. The screw 52 is threaded with a nut 54. Through the cooperation between the screw 52 and the nut 54, the nut 54 and its upper The device will rotate, and the nut 54 is fixed to the stirring frame 53 .

[0...

Embodiment 3

[0041] On the basis of Example 2, as Figure 9-10 As shown, also includes a feeding mechanism 6, the feeding mechanism 6 is arranged on the stirring mechanism 5, and the feeding mechanism 6 is used to make the waterproof material spread on the inner wall of the arc-shaped spillway, and the feeding mechanism 6 includes a second fixed The frame 61, the rotating plate 62, the second torsion spring 63, the second wedge frame 64 and the guide frame 65, the seventh fixing frame 51 is connected with the second fixing frame 61, and the second fixing frame 61 is rotatably connected with the rotating plate 62 , a pair of second torsion springs 63 are connected between the rotating plate 62 and the second fixed frame 61. The second torsion springs 63 are used to drive the rotating plate 62 to reset. The first sliding frame 11 is connected with a pair of second wedge-shaped frames 64. The two wedge-shaped frames 64 are used to push the rotating plate 62 to rotate, and a guide frame 65 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com