Device and method for adjusting distance between rear guide and guard rollers of a rolling guide and guard

A technology of guide rollers and wheel spacing, which is used in guiding/positioning/aligning devices, rolling mill control devices, metal rolling, etc., can solve the problems of large space occupied by protective covers, high installation accuracy requirements, and high worm gear prices. Achieve the effect of less difficulty in installation and adjustment, low cost of spare parts and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

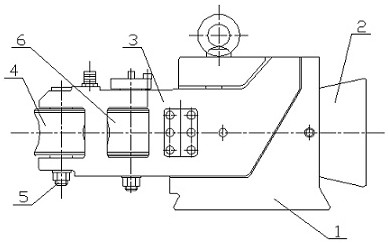

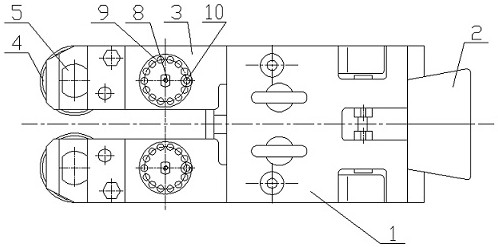

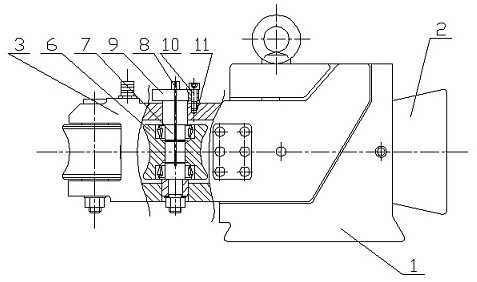

[0025] Below in conjunction with accompanying drawing, the present invention will be further described by examples.

[0026] Refer to attached Figure 1-6 , a device for adjusting the distance between guide rollers after a rolling guide, comprising a guide box body 1, a guide inlet insert 2, a guide roller support arm 3, two front guide rollers 4 and two rear guides The roller 6 and the guide and guard inlet insert 2 are bell-mouthed structures with large openings in the incoming steel direction and small openings in the steel tapping direction. Two rear guide rollers 6 and two leading guide rollers 6 and two leading guide rollers 6 are arranged in sequence in the steel tapping direction of the guide and guard entrance insert 2 . The guard roller 4, the two front guide guard rollers 4 are respectively installed and fixed on the front end of the guide guard roller support arm 3 through the fixed shaft 5, the guide guard roller support arm 3 is fixed on the guide guard box body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com