Assembling equipment for LED lamp strip

A technology for LED light strips and assembling equipment, applied in mechanical equipment, metal processing equipment, metal processing and other directions, can solve the problems of slow efficiency, crooked light strips, falling off and separation of light strips and lamp sockets, etc. Efficient implementation, avoiding inefficiency effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

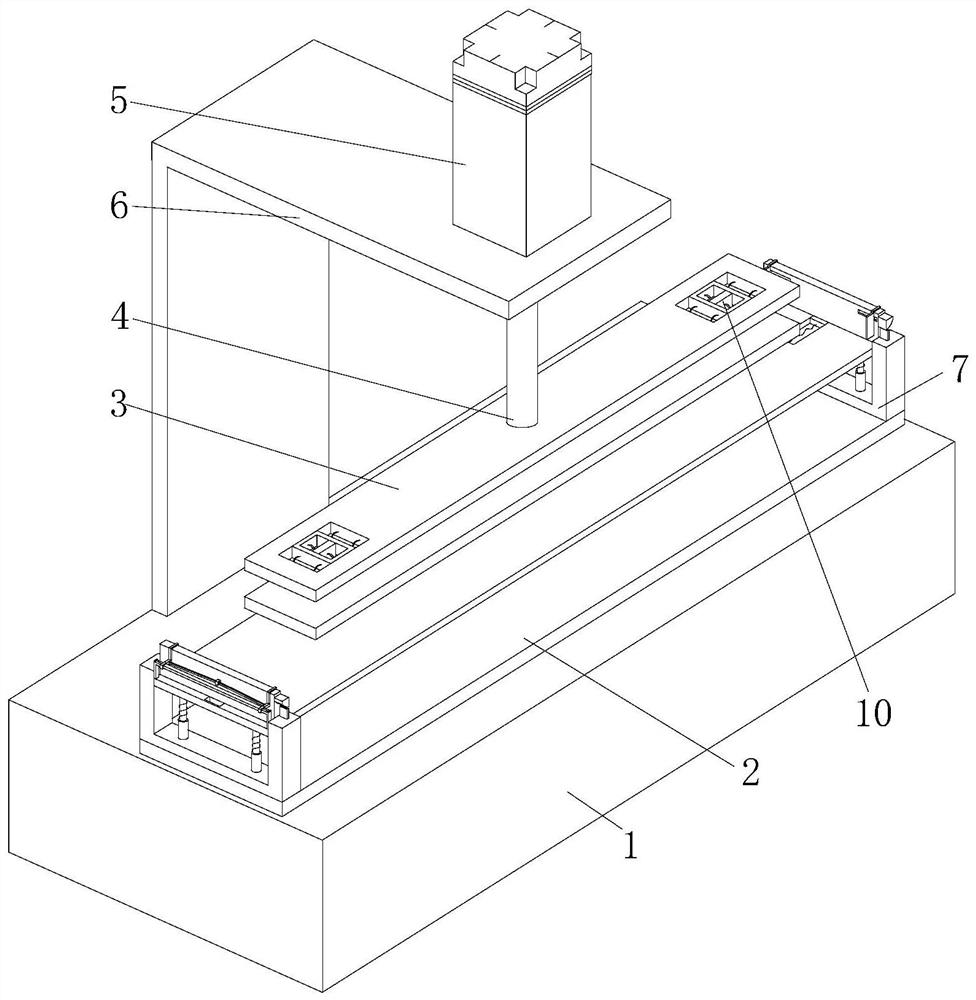

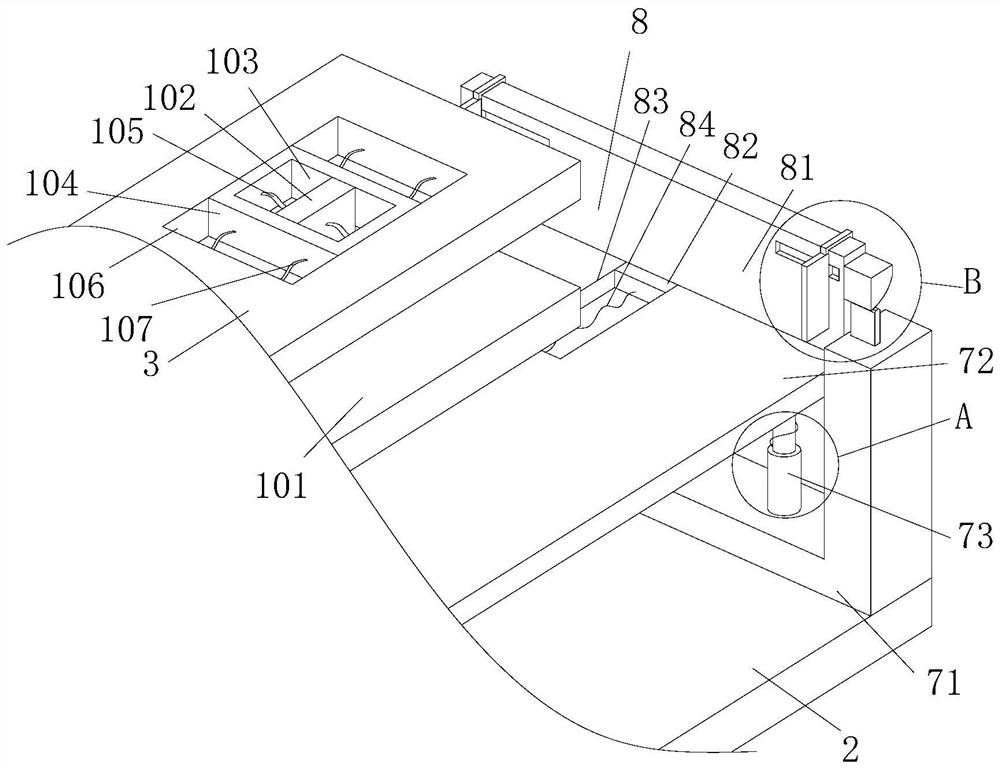

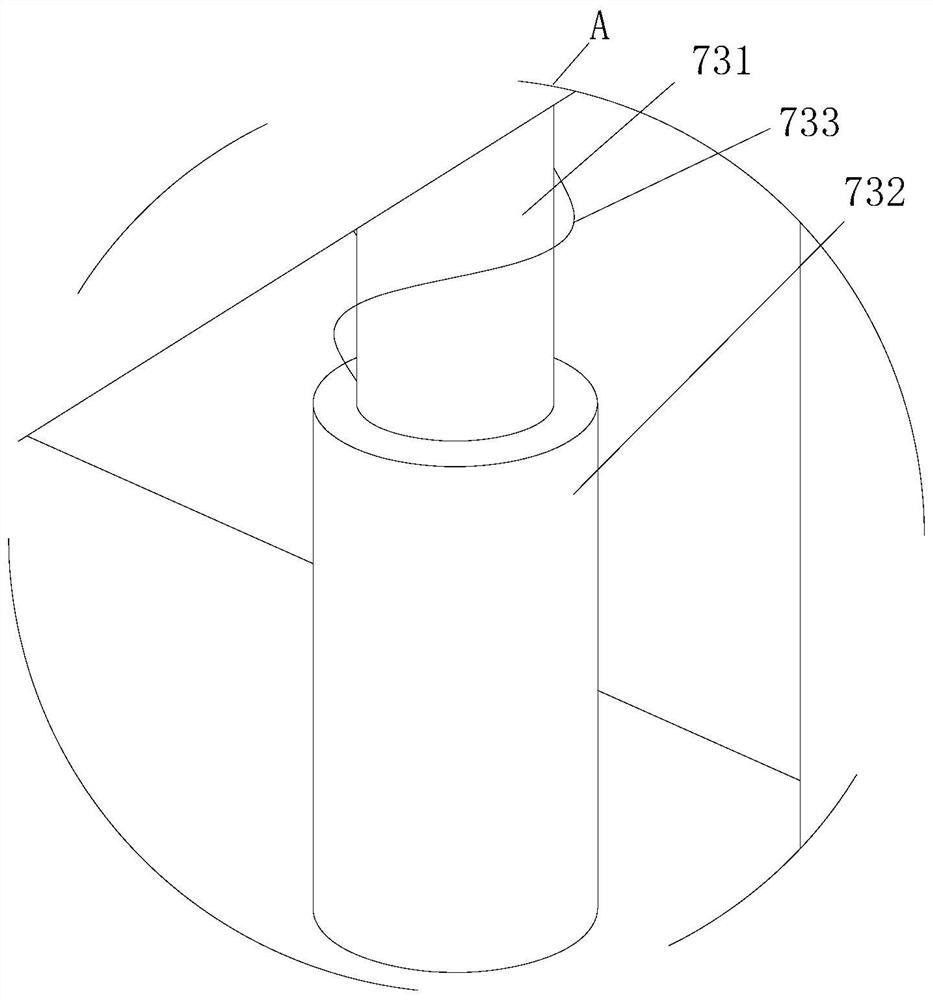

[0032] Attached below Figure 1-5 The present invention is further described with embodiment:

[0033]An assembly device for LED light bars, comprising a workbench 1 and a support plate 2, the support plate 2 is fixedly connected to the upper end surface of the workbench 1, and the support plate 2 is provided with an assembled LED light bar and The lamp holder, and the LED light bar and the lamp holder are adhered by glue, and the pressing plate 3 is arranged directly above the supporting plate 2, and the upper end surface of the pressing plate 3 is fixedly connected with the driving cylinder arm 4, and the driving cylinder The upper end of arm 4 is connected with the driving end of drive cylinder 5, and drive cylinder 5 is fixedly arranged on the support frame 6, and support frame 6 is fixedly arranged on the upper end face of workbench 1, has set up supporting plate 2 among the present invention, bearing The supporting plate 2 is used to support the assembly structure of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com