Automatic silicon rod bonding production line

An automatic production line and production line technology, applied in the direction of manufacturing tools, stone processing equipment, fine working devices, etc., can solve the problems of time-consuming and laborious, low processing and production efficiency, and achieve the effect of improving processing and production efficiency, convenient and fast production and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

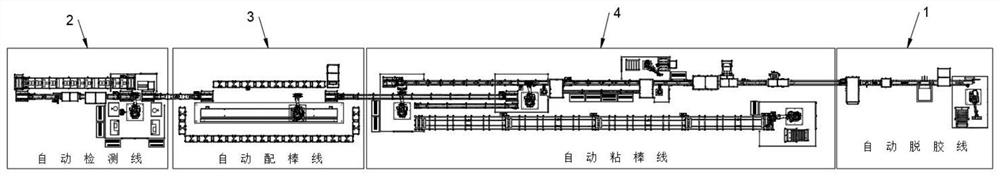

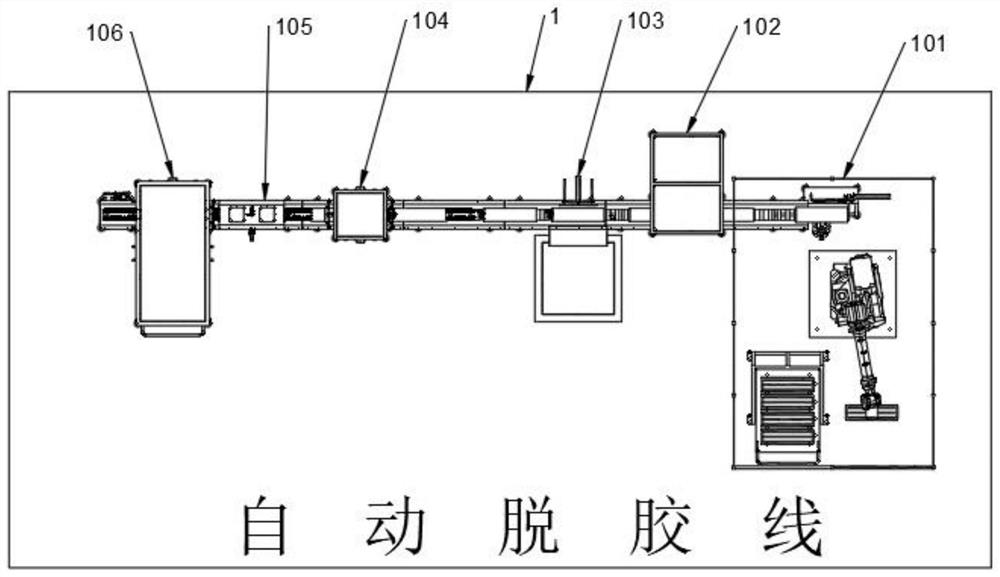

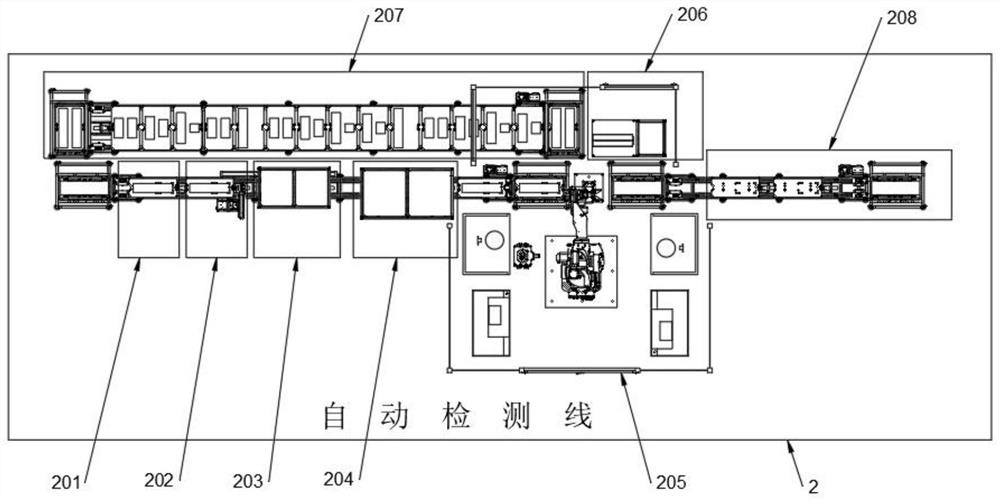

[0023] Such as Figure 1-5 As shown, a silicon rod bonding automatic production line proposed by an embodiment of the present invention includes an automatic degumming production line 1, an automatic detection production line 2, an automatic rod distribution production line 3 and an automatic sticking rod production line 4, and the automatic degumming production line 1 successively includes crystal Tray loading and turning unit 101, high-frequency degumming unit 102, plastic plate removing unit 103, crystal tray grinding unit 104, crystal tray washing unit 105 and crystal tray unloading unit 106, the automatic detection production line 2 includes the silicon rod loading station in sequence Unit 201, silicon rod coding station unit 202, silicon rod detection station unit 203, silicon rod length detection station unit 204, silicon rod minority carrier flaw detection station unit 205, one of silicon rod minority carrier flaw detection station unit 205 A silicon rod end face detec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com