Passenger car roof interior trim assembly structure and assembly process thereof

A technology for assembly structure and interior decoration, applied in the direction of upper structure, upper structure sub-assembly, motor vehicles, etc., can solve problems such as shedding, non-stick leather, complicated installation process, etc. less demanding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

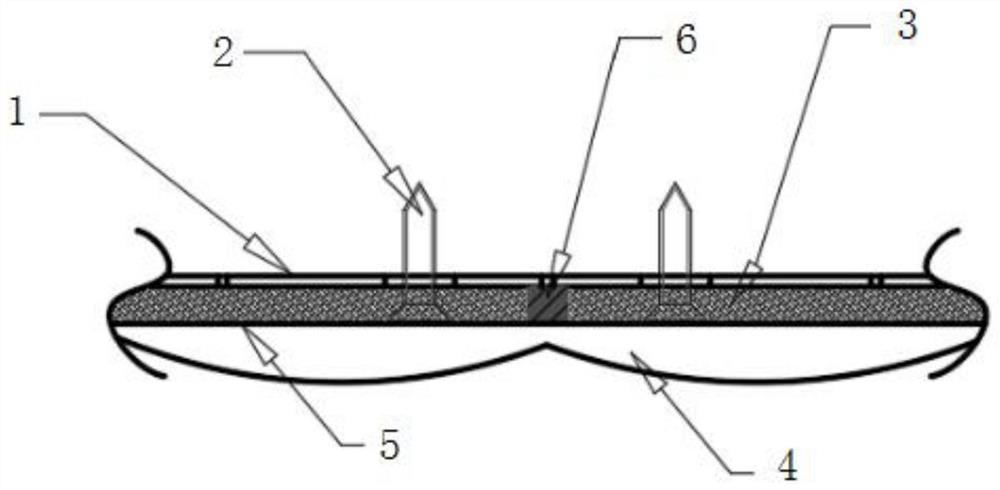

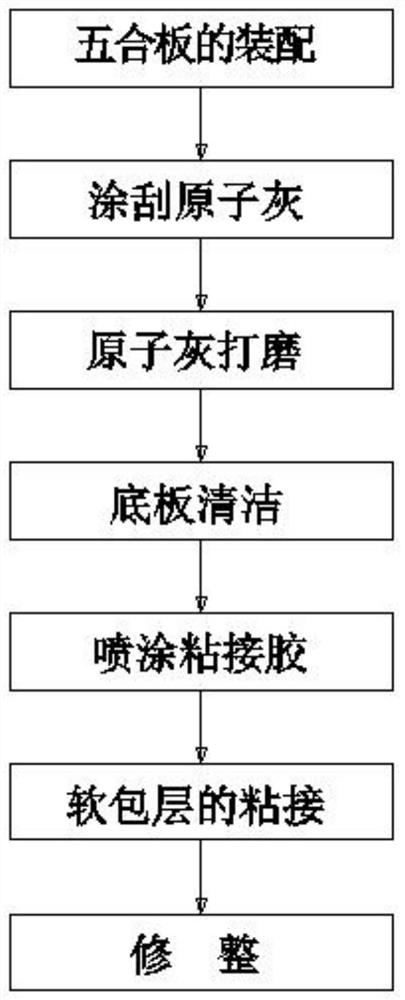

[0028] Such as figure 1 As shown, a passenger car roof interior assembly structure includes a roof frame 1 for support and a soft cladding 4 for decoration on the exposed surface of the roof, and the roof frame 1 is connected by a plurality of self-tapping screws 2 There is one layer of five-plywood 3, and the soft cladding 4 is connected to the outer surface of the five-plywood 3 by adhesive glue 5.

[0029] Putty putty 6 is filled in the gap between two adjacent five-plyboards 3 , and the height of the exposed surface of the putty putty 6 is flush with the outer surface of the five-plywood board 3 . The self-tapping screw 2 adopts a cross countersunk head self-tapping screw. After the self-tapping screw 2 is connected in place, the countersunk hole on the five-ply plate 3 and the head of the self-tapping screw 2 are filled and smoothed by putty 6 to ensure adhesion. Flatness of the interface.

[0030] The adhesive glue 5 adopts SX-001 adhesive, and the SX-001 adhesive is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com