Carton turnover mechanism

A technology of overturning mechanism and cardboard box, which is applied in the direction of conveyors, typewriters, conveyor objects, etc., which can solve the problems of waste, inability to spray codes, and inability to print required information, etc., and achieves convenient installation and maintenance and simple overall structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

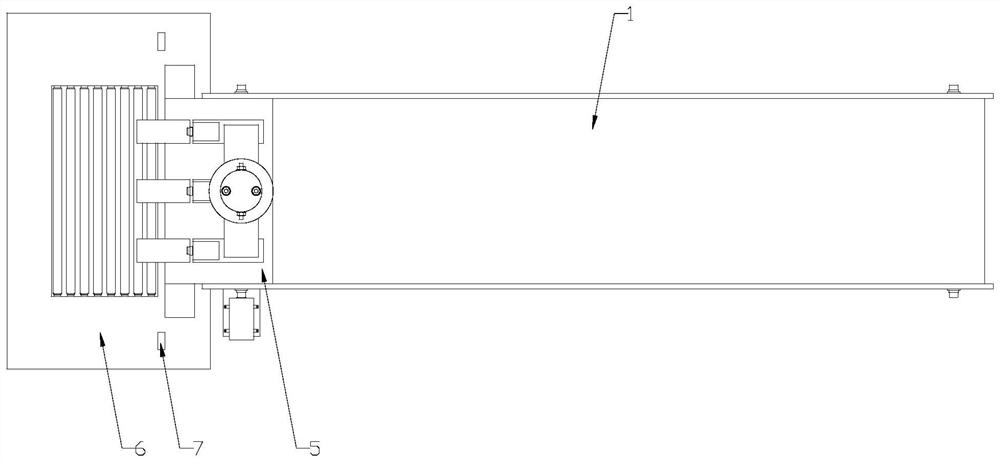

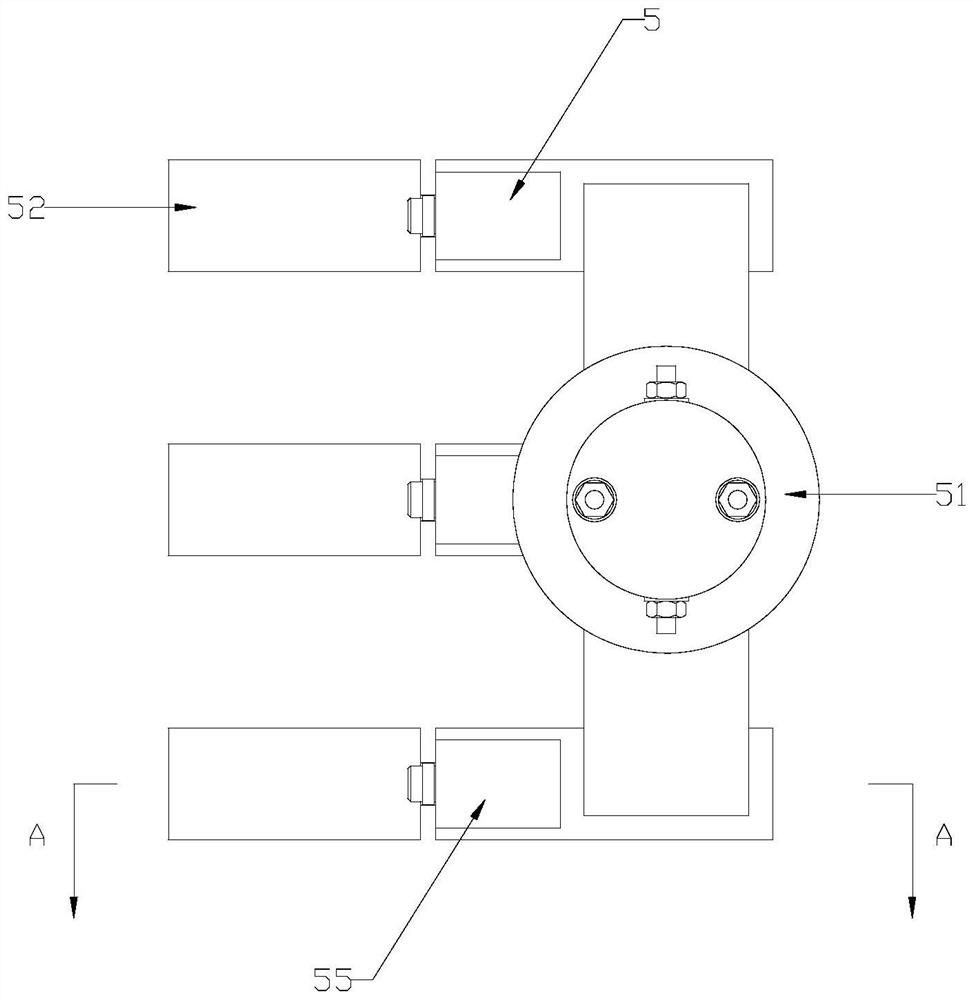

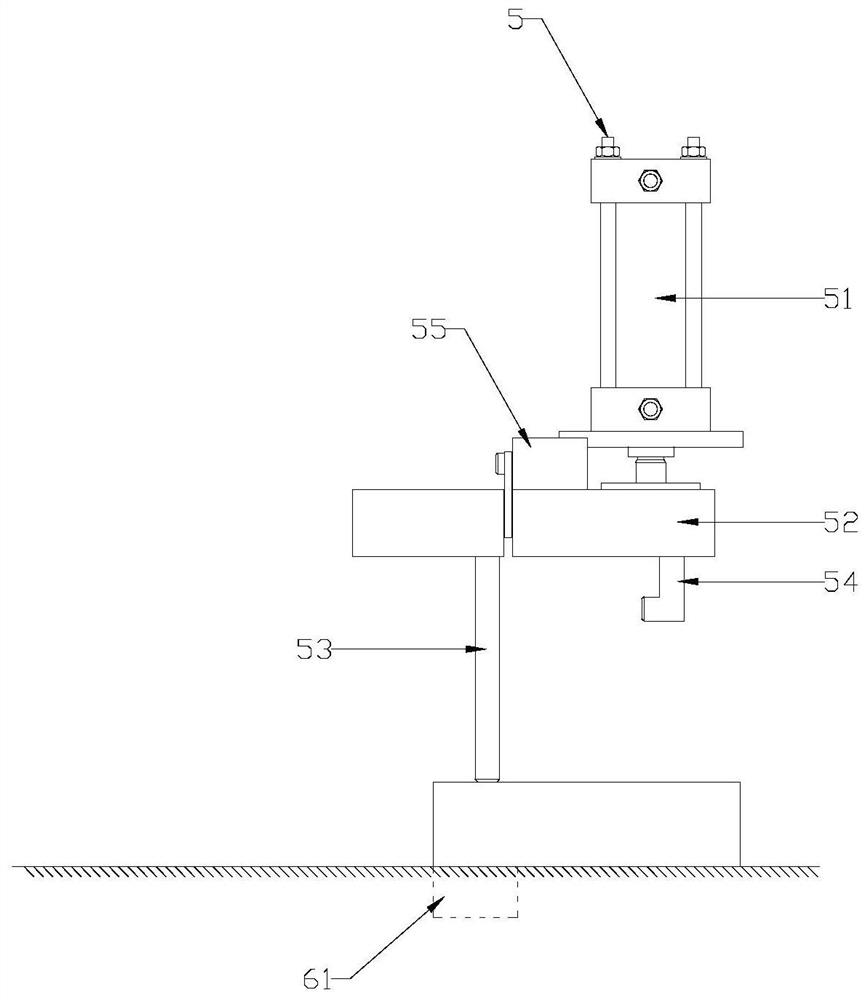

[0019] refer to Figure 1 to Figure 7 , a cardboard box turnover mechanism of the present invention, comprising a conveyor belt 1, a flipper 5, a table body 6, a position sensor 7 and an electric control cabinet, the table body 6 is installed at the exit of the conveyor belt 1 and the top surface of the table plate is set There is a card box groove 61, and the flipper 5 includes a flipping cylinder 51, a flipping seat 52, a pressing assembly 53 and a feeding assembly 54, and the flipping cylinder 51 is located above the outlet of the conveyor belt 1 and the end of the telescopic rod Set downwards and be connected with several turning seats 52, the material pressing assembly 53 and the material dumping assembly 54 are respectively installed in the bottom surface of the turning seat 52, the pressing material rods of the pressing material assembly 53 and the material dumping assembly 54 531 and the dump rod 541 can be driven by the pressing driver and the dump driver respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com