Adhesive for LED lamp tube plate

A technology of LED lamp tubes and adhesives, applied in the direction of adhesive types, conjugated diene adhesives, adhesives, etc., can solve the problems of moisture absorption of polyimide film and epoxy glue, curling of copper clad laminates, and the impact of Sticking lamp bead technology and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

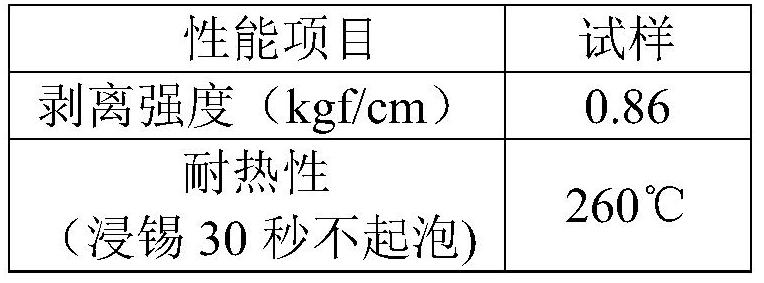

Examples

no. 1 example

[0043] The adhesive provided by the present invention for LED lamp tube board, by weight, the adhesive includes,

[0044] 15-45 parts of halogen-free epoxy resin, the halogen-free epoxy resin is low hygroscopic epoxy resin, and the halogen-free epoxy resin is dicyclopentadiene phenolic resin;

[0045] 15-45 parts of nitrile rubber;

[0046] 0.1-8 parts of curing agent;

[0047] Phosphorus-containing composite flame retardant 5-60 parts;

[0048] 0.1-5 parts of additives.

[0049] The curing agent includes imidazole curing agent and dicyandiamide curing agent.

[0050] In this embodiment, by weight, there are 15 parts of halogen-free epoxy resin, 45 parts of nitrile rubber, 5.95 parts of curing agent, 32 parts of phosphorus-containing composite flame retardant, 2 parts of auxiliary agent, and 0.05 parts of accelerator. share.

[0051] The adhesive provided by the present invention can be obtained by mixing and fully stirring the above materials. The stirring device can be ...

no. 2 example

[0058] The halogen-free epoxy resin is low moisture absorption epoxy resin, and the halogen-free epoxy resin is dicyclopentadiene phenolic resin.

[0059] The curing agent includes imidazole curing agent and dicyandiamide curing agent.

[0060] In this embodiment, by weight, there are 30 parts of halogen-free epoxy resin, 30 parts of nitrile rubber, 5.95 parts of curing agent, 32 parts of phosphorus-containing composite flame retardant, 2 parts of auxiliary agent, and 0.05 parts of accelerator. share.

[0061] The adhesive provided by the present invention can be obtained by mixing and fully stirring the above materials. The stirring device can be a known stirring device. The adhesive provided by the present invention uses a halogen-free epoxy resin with low hygroscopicity. Chain resin to avoid moisture absorption. On the one hand, the copper clad laminate does not need to be curled due to moisture absorption, which ensures the production efficiency of the subsequent lamp bea...

no. 3 example

[0068] The halogen-free epoxy resin is low moisture absorption epoxy resin, and the halogen-free epoxy resin is dicyclopentadiene phenolic resin.

[0069] The curing agent includes imidazole curing agent and dicyandiamide curing agent.

[0070] In this embodiment, by weight, there are 35 parts of halogen-free epoxy resin, 30 parts of nitrile rubber, 5.95 parts of curing agent, 27 parts of phosphorus-containing composite flame retardant, 2 parts of auxiliary agent, and 0.05 parts of accelerator. share.

[0071] The adhesive provided by the present invention can be obtained by mixing and fully stirring the above materials. The stirring device can be a known stirring device. The adhesive provided by the present invention uses a halogen-free epoxy resin with low hygroscopicity. Chain resin to avoid moisture absorption. On the one hand, the copper clad laminate does not need to be curled due to moisture absorption, which ensures the production efficiency of the subsequent lamp bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com