Adjusting method for turbine gasket of vaneless turbine and turbine

An adjustment method and turbine technology, applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve problems such as non-adjustment methods, difficult disk body processing, unfavorable maximum performance, etc., to achieve high output power, improve the operating efficiency of the body, good uniform effect

Inactive Publication Date: 2021-08-27

深圳朴坂科技有限公司

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] However, although the smooth disk of the turbine can reduce the difficulty of production, it is not the optimal deployment method. The disk body is improved, and the output power of the radial bladeless turbine through the pressure difference is higher than that of the traditional bladeless turbine. Great improvement, but the improvement of the disc body will lead to greater difficulties in the processing of the disc body, which increases the production cost

At the same time, due to different working media, the requirements for diversion are also different. If the diversion channel involved is fixed on the disk body, it is not conducive to obtaining the maximum performance.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

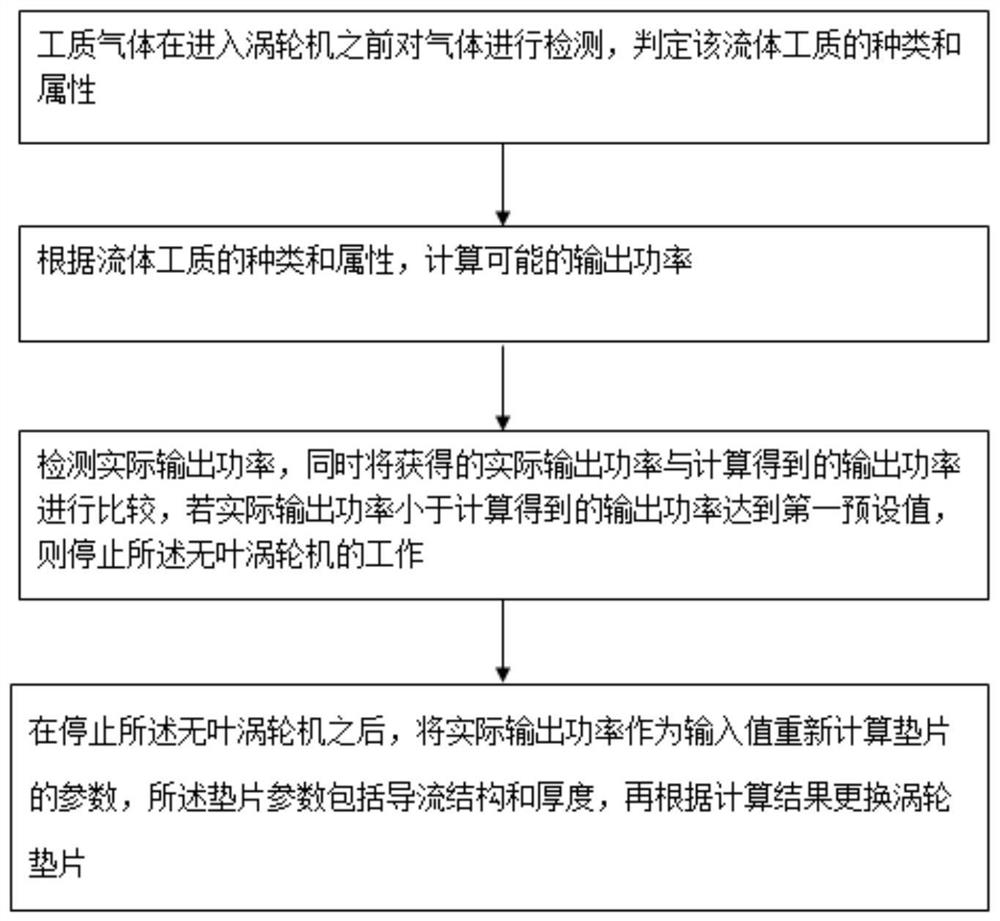

[0025] like figure 1 As shown, this embodiment discloses a method for adjusting the turbine gasket of a vaneless turbine. The disk body of the bladeless turbine with pressure difference is a smooth disk body, and there is a turbine gasket between any two disk bodies. The entry or exit trajectory of the fluid working medium is controlled by a turbine gasket with a specific geometric figure, and the adjustment method includes:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

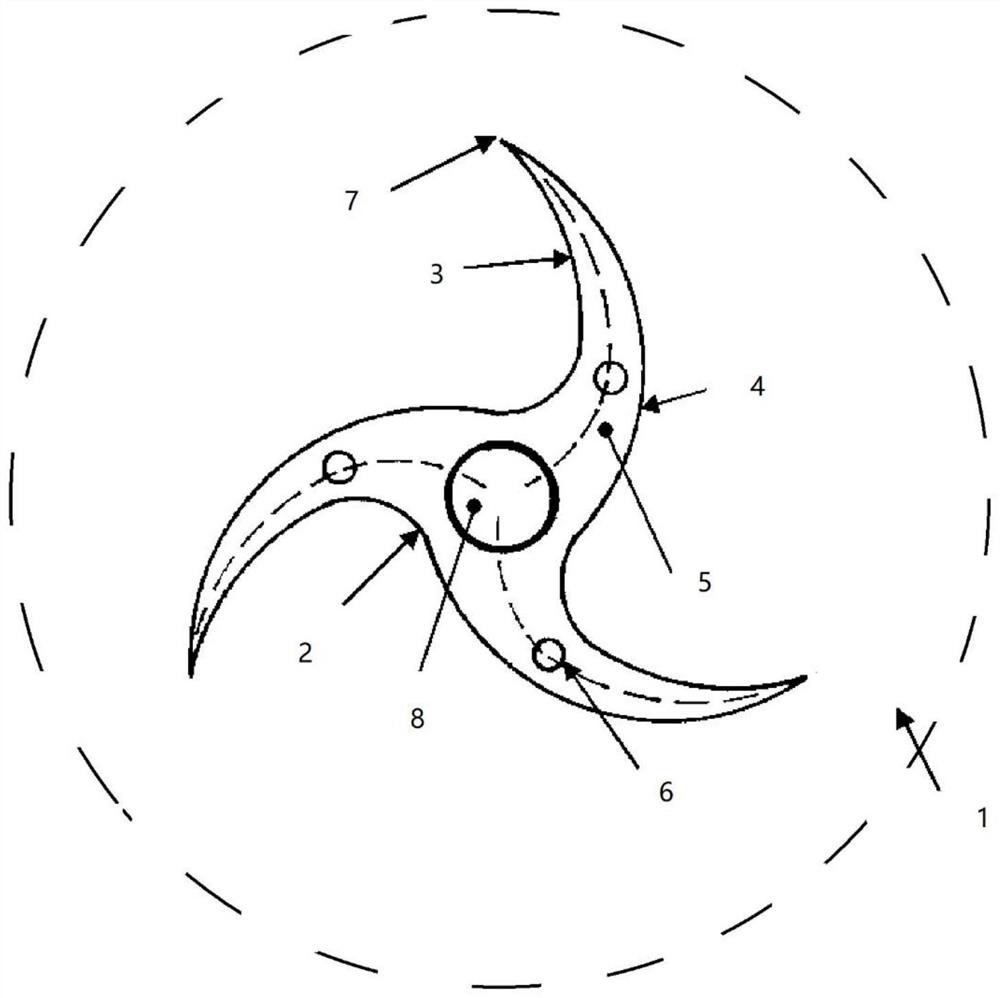

The invention discloses an adjusting method for a turbine gasket of a vaneless turbine, wherein disc bodies of a pressure difference vaneless turbine are smooth disc bodies, the turbine gasket is arranged between any two disc bodies, and the turbine controls the inlet or outlet track of a fluid working medium through the turbine gasket with a specific geometric figure. The method comprises the steps: detecting working medium gas before entering the turbine to judge the type and the attribute of the fluid working medium; calculating possible output power according to the type and the attribute of the fluid working medium; detecting actual output power, and meanwhile, comparing the obtained actual output power with the calculated output power, and if the actual output power is smaller than the calculated output power and reaches a first preset value, stopping work of the vaneless turbine; after the vaneless turbine is stopped, taking the actual output power as an input value, and recalculating parameters of the gasket, wherein the parameters of the gasket comprise the flow guide structure and the thickness; and replacing the turbine gasket according to a calculation result.

Description

technical field [0001] The invention relates to the technical field of turbines, in particular to an adjustment method for a bladeless turbine gasket and the turbine. Background technique [0002] The principle of the bladeless turbine pulling the turbine is the boundary layer effect of the fluid. The fluid is affected by the viscous force and will form a thin boundary layer on the edge of the pipe wall or other objects. In the boundary layer, the fixed surface The velocity of the flow is 0, and the velocity increases the farther away from the surface. Using this effect, the high-speed moving liquid can drive a set of discs to rotate. It is therefore much more efficient than a normal bladed turbine. [0003] The vaneless turbine driven by fluid shear force has the characteristics of simple structure, relatively low manufacturing tolerance requirements, and outstanding sealing performance. During operation, the fluid will generate a pressure gradient (positively correlated ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F01D1/34F01D21/00

CPCF01D1/34F01D21/00

Inventor 许文伟

Owner 深圳朴坂科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com