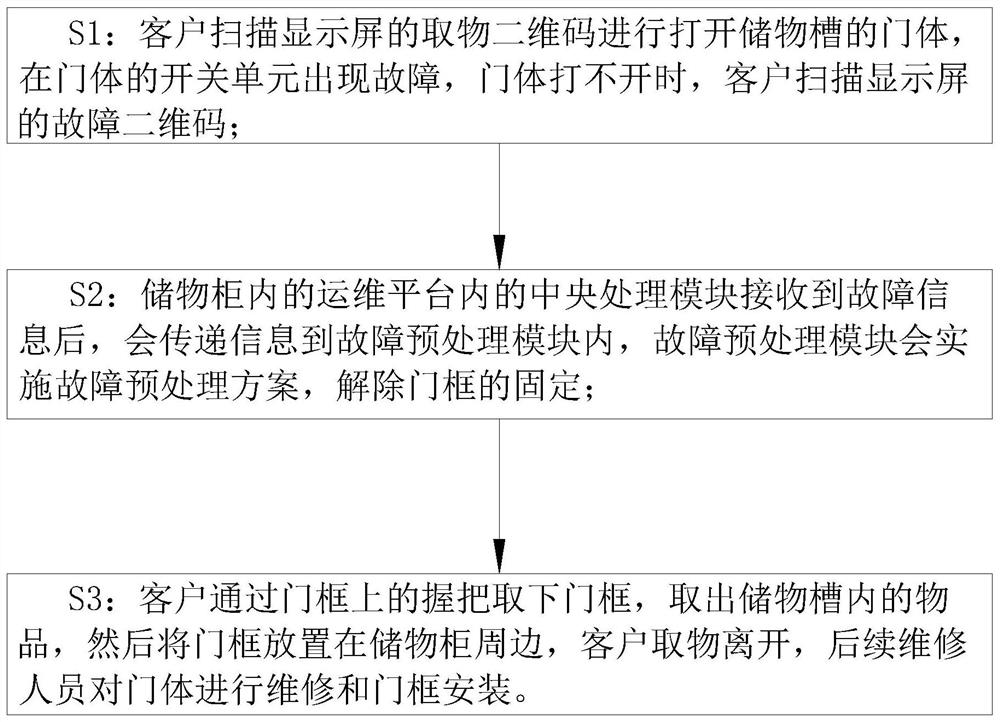

Fault plan processing method and system based on automatic operation and maintenance platform

A technology for pre-plan processing and pre-processing modules, applied in the field of operation and maintenance management, can solve problems such as switch failure, waste of waiting time, lost items, etc., to achieve the effect of convenient installation and reduction of moving friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

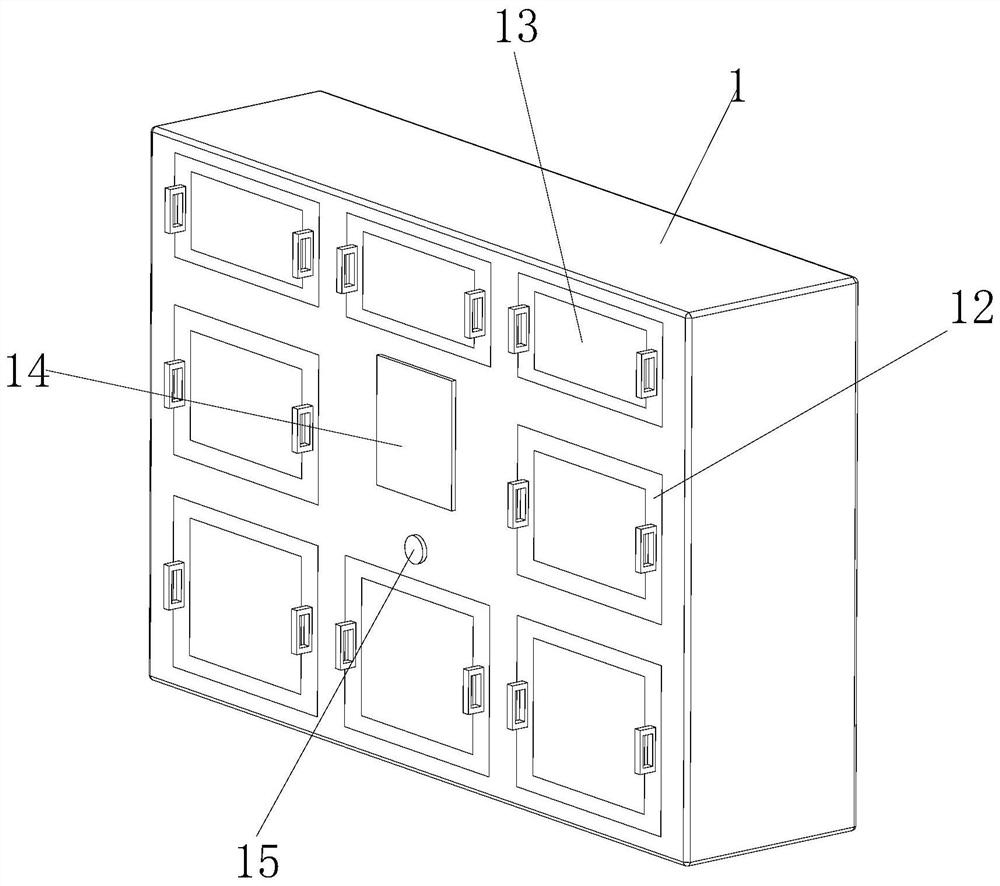

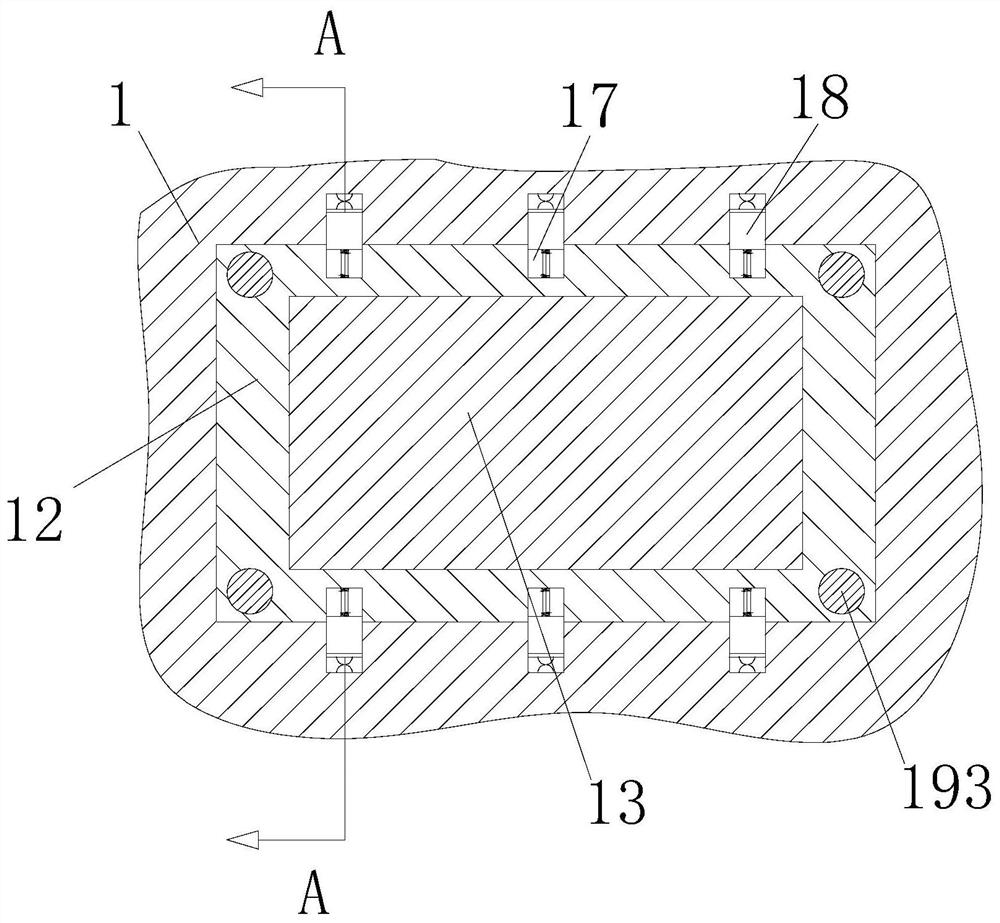

[0042] like Figure 2 to Figure 7 As shown in the figure, the fault plan processing system based on the automatic operation and maintenance platform of the present invention is applicable to the above-mentioned fault plan processing method based on the automatic operation and maintenance platform, and includes a locker 1; the locker 1 is provided with a A set of storage slots 11 of different sizes; the storage cabinet 1 is provided with a display screen 14 and a probe 15; the probe 15 is located below the display screen 14; The door frame 12 is fixed in the placement slot by a fixing member; a door body 13 is hinged in the door frame 12, and the door body 13 is opened and closed by a switch unit; the fixing member includes a first groove 17 and A first locking slot 16; a set of first grooves 17 are defined on the upper, lower and outer side walls of the door frame 12; The position block 18 is slidably connected to the side wall of the first groove 17 ; the position of the pla...

Embodiment 2

[0049] see Figure 8 to Figure 10 As shown in the comparison example 1, as another embodiment of the present invention, the side walls at both ends of the placement groove are provided with second locking grooves 4; the side walls on both sides of the door frame 12 are provided with a fourth A cavity 41, and a second push plate 42 is sealed and slidably connected in the fourth cavity 41, and the second push plate 42 is fixed on the side wall of the fourth cavity 41 by a spring; the side wall of the second push plate 42 A second locking block 44 is fixedly connected to it, and the second locking block 44 extends out of the fourth cavity 41; the handle is U-shaped; a fifth cavity is opened in the middle section of the handle, and A third push plate 45 is slidably connected in the fifth cavity; a second air bag 46 is fixedly connected between the side wall of the fifth cavity and the third push plate 45 ; the side wall of the third push plate 45 is fixedly connected There is a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com