Charging support and battery swap station

A charging stand and supporting stand technology, applied in battery circuit devices, current collectors, electric vehicles, etc., can solve the problems of poor electrical connection, low reliability, difficult to accurately locate the battery pack and charging stand, etc., and achieve charging stability. Excellent, good electrical connection reliability, good positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

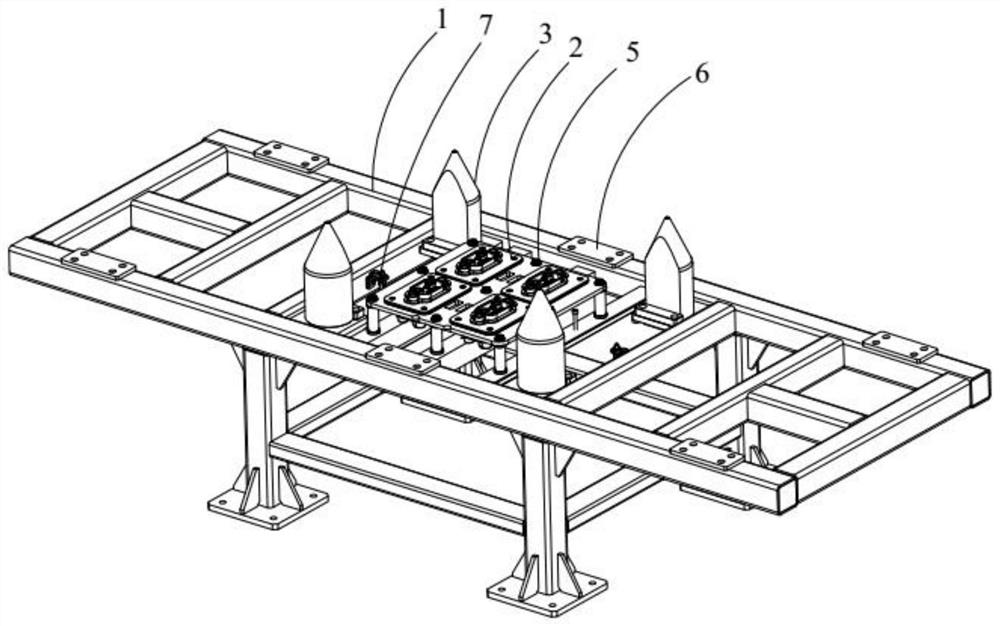

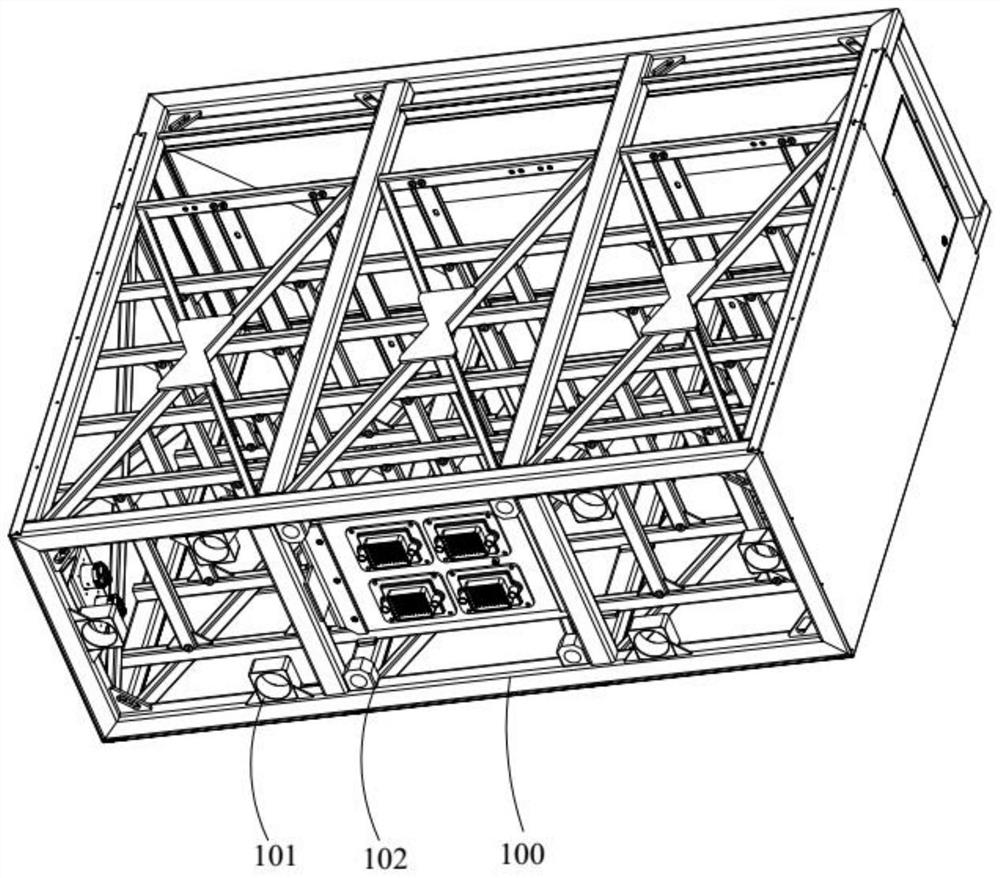

[0041] This embodiment provides a charging stand, such as Figure 1-Figure 2 As shown, it is used for charging the battery pack 100 . The charging stand includes a fixing seat, a supporting frame 1 and an electrical connection mechanism 2, and the supporting frame 1 is arranged on the fixing seat. The fixing base specifically includes four uprights, and the four uprights serve as feet to jointly carry the support frame 1 to realize support for the support frame 1 . The support frame 1 is a frame structure with light weight, and the support frame 1 is used to carry the battery pack 100 to ensure that the battery pack 100 has good support strength during charging. It should be noted that, in the existing battery pack, generally several battery cells are electrically connected together to form an integral battery pack, which is completely different from the structure of the battery pack 100 provided in the embodiment and the existing battery pack. The battery pack 100 of this e...

Embodiment 2

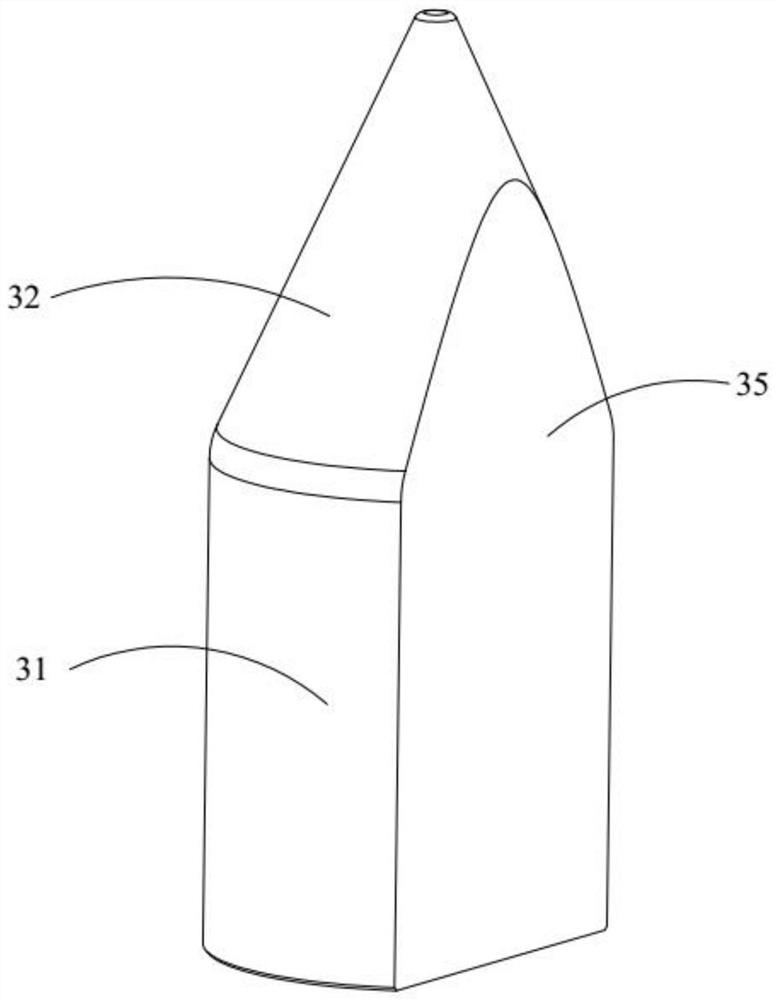

[0058] Compared with the first embodiment, this embodiment differs only in the specific structure of the first positioning column 3 , so the same parts will not be repeated here. like Figure 4 As shown, the support portion 31 of the first positioning column 3 provided in this embodiment is no longer a columnar structure, and the outer diameter of the support portion 31 gradually decreases toward the tip portion 32 , increasing the transition range. The tip portion 32 is no longer a cone structure, but the tip portion 32 is a columnar structure. It is equivalent to the opposite of the cylindrical shape and the tapered shape of the first embodiment. In this way, the support portion 31 can better transition to the tip portion 32, ensuring that the first positioning column 3 and the first positioning guide sleeve can Smooth introduction, good smoothness.

Embodiment 3

[0060] Compared with the second embodiment, the present embodiment differs only in the specific structure of the first positioning column 3 , so the same parts will not be repeated here. like Figure 5 As shown, the outer diameter of the support portion 31 in the first positioning column 3 provided in this embodiment gradually decreases toward the direction close to the tip portion 32 , and the outer diameter of the tip portion 32 gradually decreases toward the direction away from the support portion 31 . Optionally, the tip part 32 and the support part 31 can be integrally formed to form a conical structure. Compared with the second embodiment, this embodiment avoids the step between the support part 31 and the tip part 32 to affect the introduction effect, so that the transition from the bottom of the support part 31 to the top of the tip part 32 can be directly and smoothly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com