Indexable non-standard double-edge cutting and grooving blade for numerical control

A blade and non-standard technology, which is applied in the direction of lathe tools, accessories of toolholders, turning equipment, etc., can solve the problems of long manufacturing cycle, difficult frictional heat, increased cutting force, etc., and achieve good positioning accuracy and installation firm effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

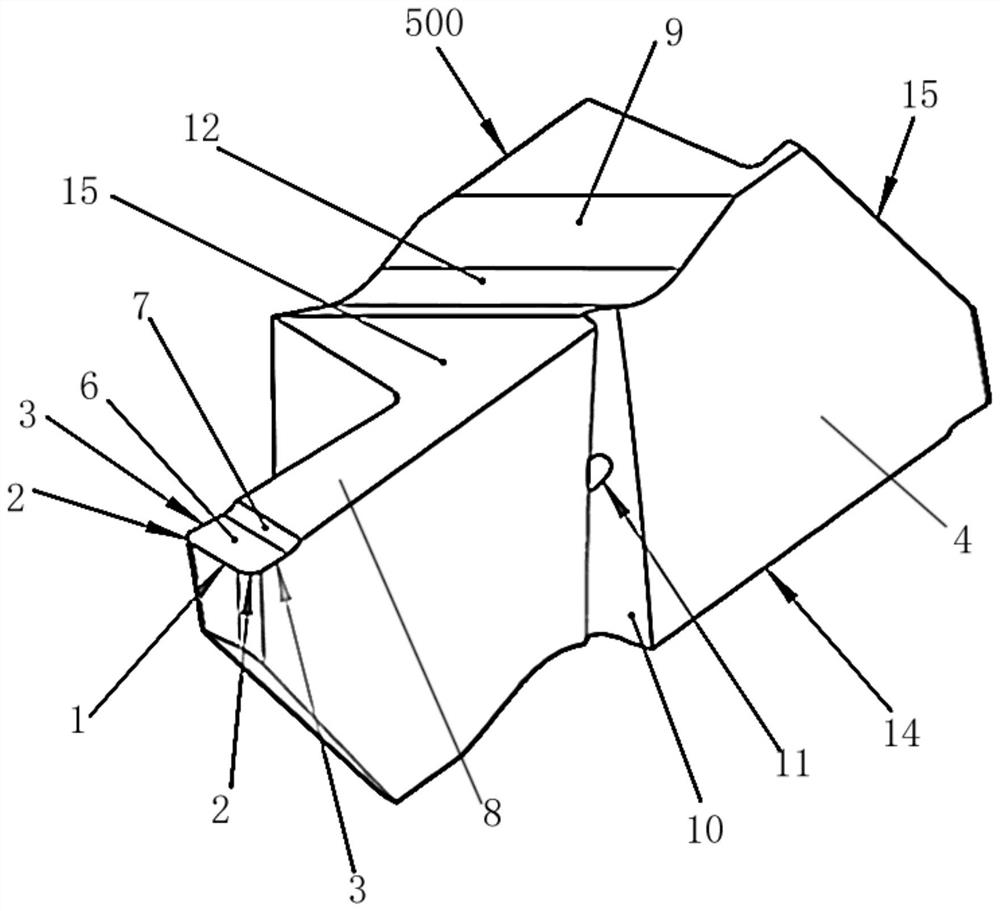

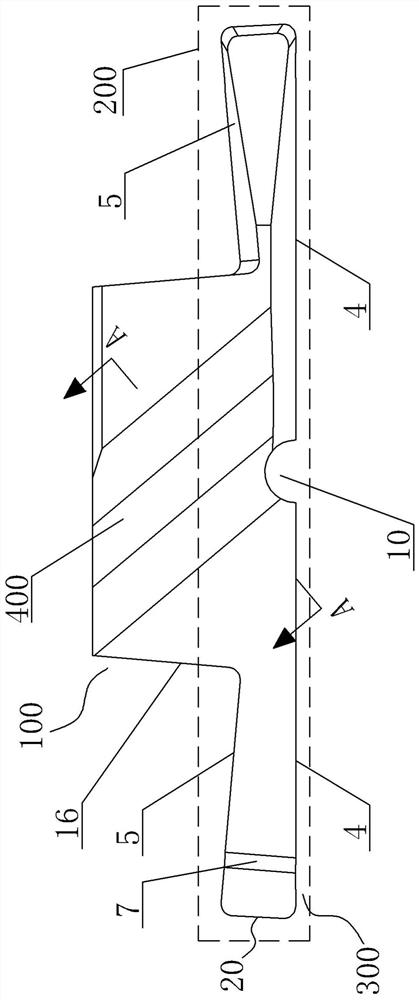

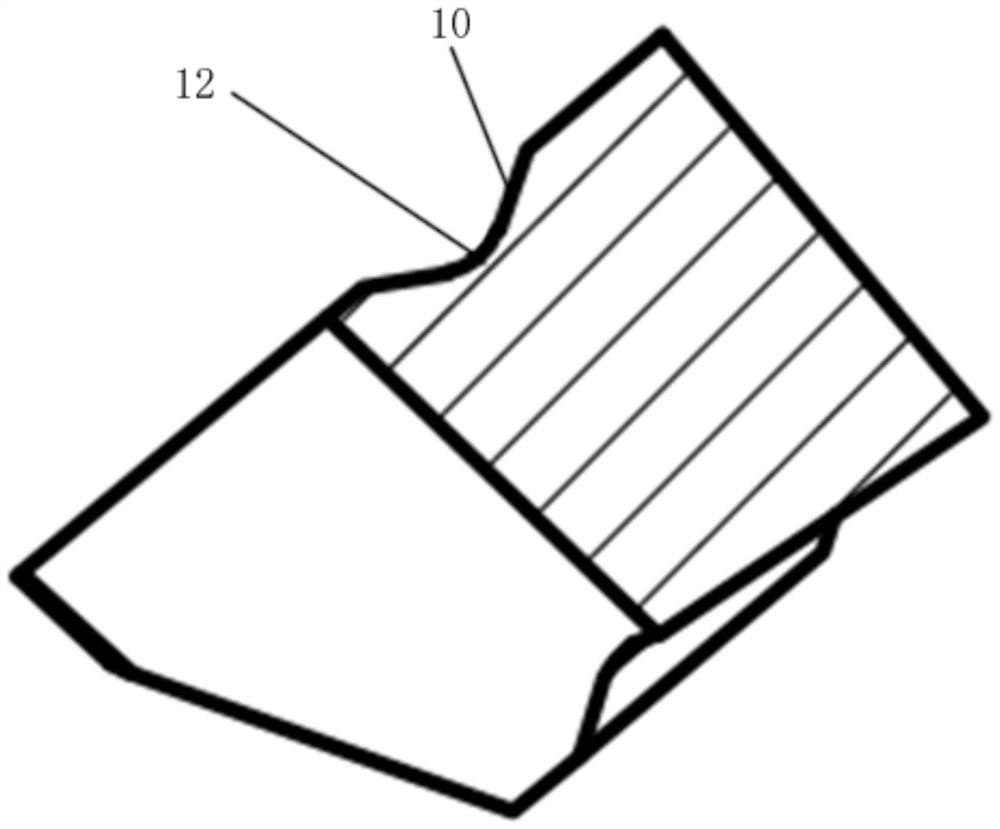

[0017] A non-standard double-edged parting and grooving blade for CNC indexable, see Figure 1-Figure 4 : It comprises a blade body 100, wherein a pair of diagonal positions of the cutting end 200 at the axially outer end of the blade body 100 are respectively provided with cutting unit parts 300, and any one cutting unit part 300 rotates 180° under the cutting state of the blade body 100 coincide with another stationary cutting unit part 300, each cutting unit part 300 includes a cutting edge, a chip breaker, and a chip guiding part. The cutting edge includes a main cutting edge 1 and an arc cutting edge 2. The main cutting edge The two sides of 1 are connected to the starting end of the arc cutting edge 2 on the corresponding side, the outer end of the arc cutting edge 2 is respectively connected to the corresponding minor cutting edge 3, and the outer end surface 4 and the inner side of the two minor cutting edges 3 correspond to The end surface 5 is concavely arranged from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com