Battery separators and lead-acid batteries

A battery separator, lead-acid battery technology, applied in secondary batteries, lead-acid batteries, battery pack components, etc., can solve the problems of uneven acid filling rate, high filling time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

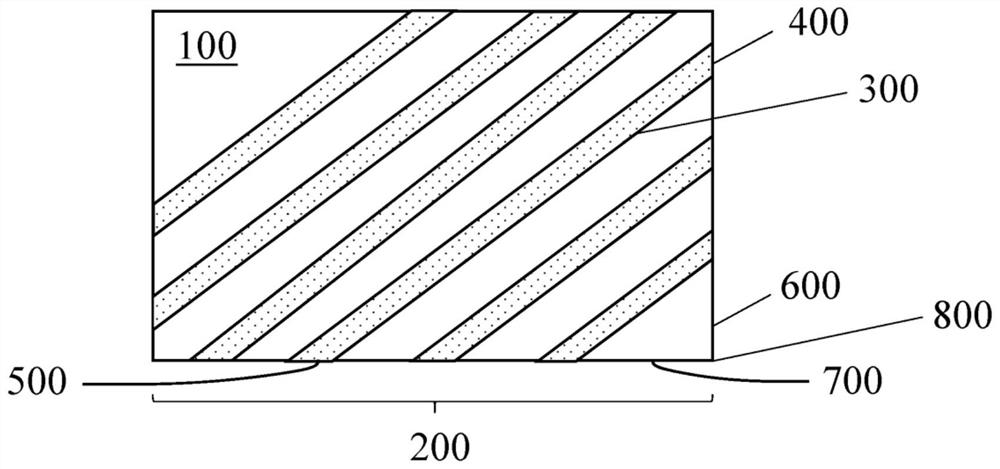

[0123] This example describes the production of an embossed separator suitable for use in AGM batteries and compares the physical properties of an embossed separator to that of a separator formed from the same furnish.

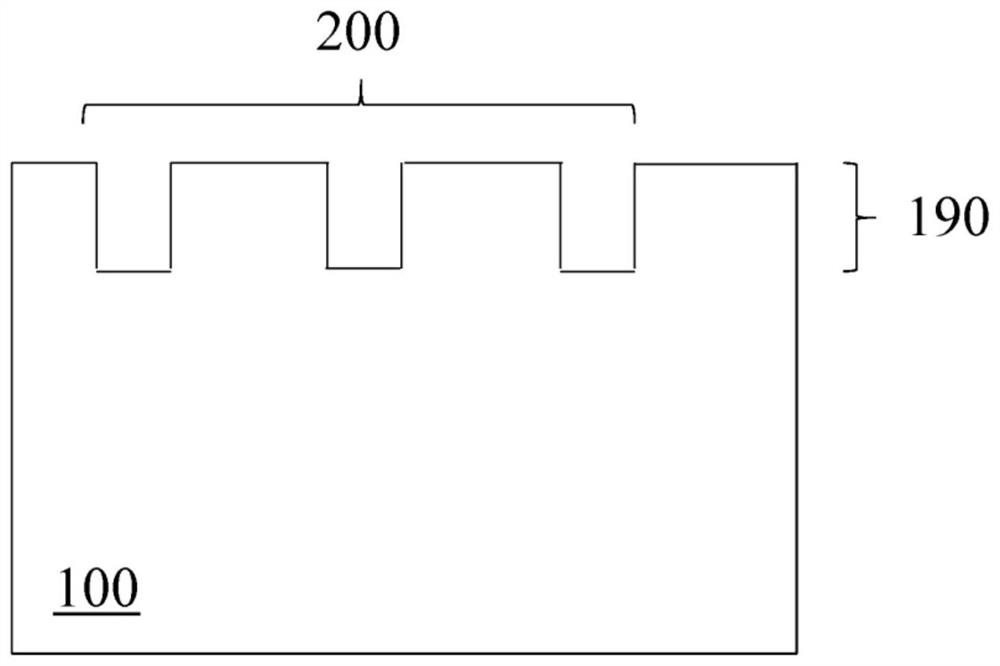

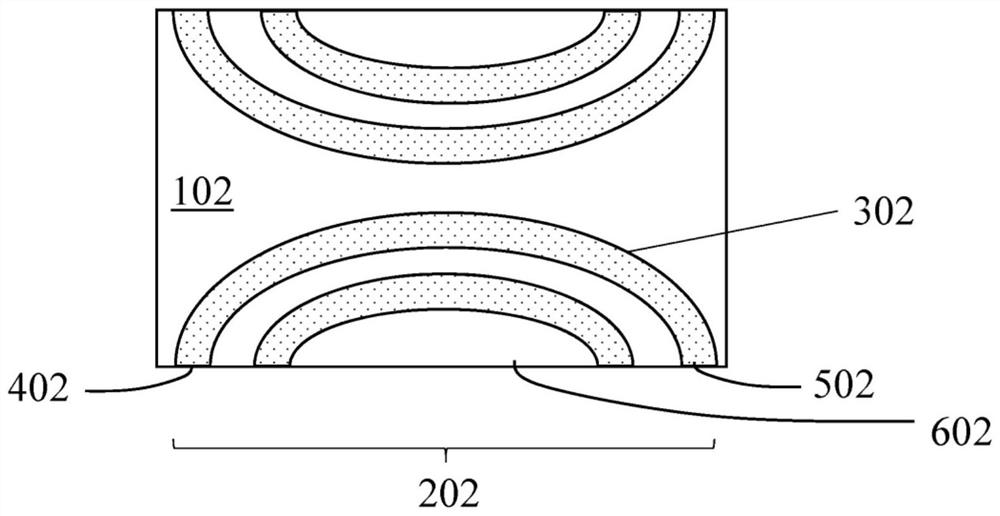

[0124] Three partitions were formed by a wet-laid process from the furnish shown in Table 1: one partition lacked protrusions; one partition included continuous protrusions in the form of straight lines at an angle of 45° to the machine direction; and one partition The plate comprises discrete protrusions in the form of ovals having a length of 27 mm and a width of 4 mm. In separators comprising projections, the projections are formed by passing the wet-laid layer formed from the furnish while still wet through two press rolls. One of these press rolls had a raised pattern on the surface of the press roll corresponding to the pattern embossed into the wet-laid layer. The wet-laid layer is then dried.

[0125] After fabrication, each separator was laminated b...

example 2

[0133] This example describes the production of a second embossed separator suitable for use in AGM batteries, and compares the physical properties of the second embossed separator to that of a separator formed from the same formulation.

[0134]Two separators were formed by a wet-laid process from the furnishes shown in Table 3: one separator lacking protrusions; and one separator comprising continuous protrusions in the form of straight lines at an angle of 45° to the machine direction. In separators comprising projections, the projections are formed by passing the wet-laid layer formed from the furnish while still wet through two press rolls. One of the press rolls had a raised pattern on the surface of the press roll corresponding to the pattern embossed into the wet-laid layer. The wet-laid layer is then dried.

[0135] After fabrication, each separator was laminated between two clear poly(carbonate) plates by the process described in Example 1, compressed, and filled wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap