A cable tray for rail vehicle end

A technology for rail vehicles and cable trays, which is applied to the field of cable trays at the end of rail vehicles, can solve the problems of inconvenient separation of left and right line pipelines, poor structural stability of hangers, easy rusting of support rods, etc. The effect of low production cost, easy installation, use and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is introduced below by accompanying drawing.

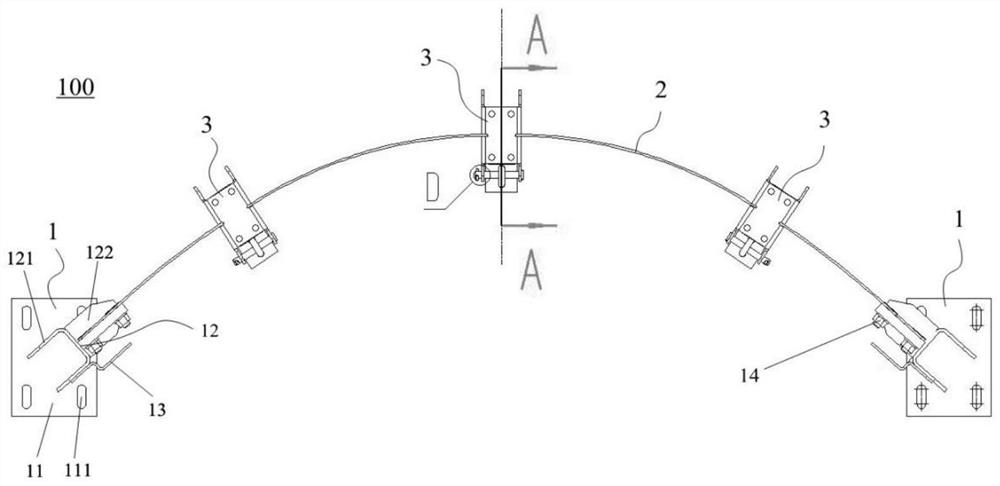

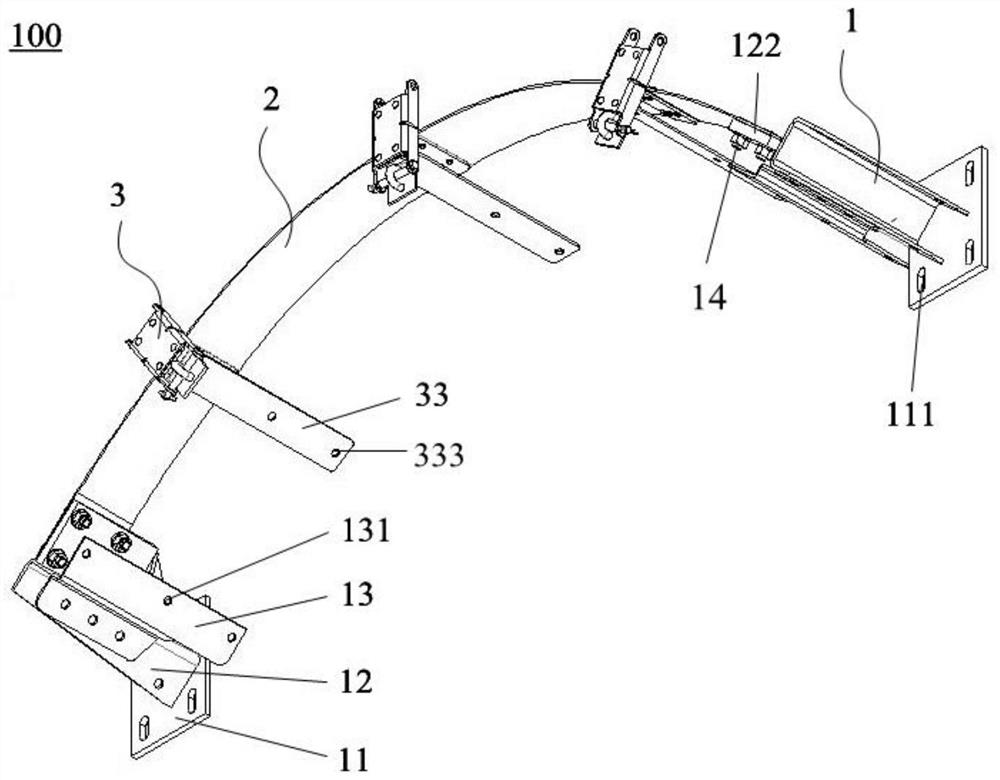

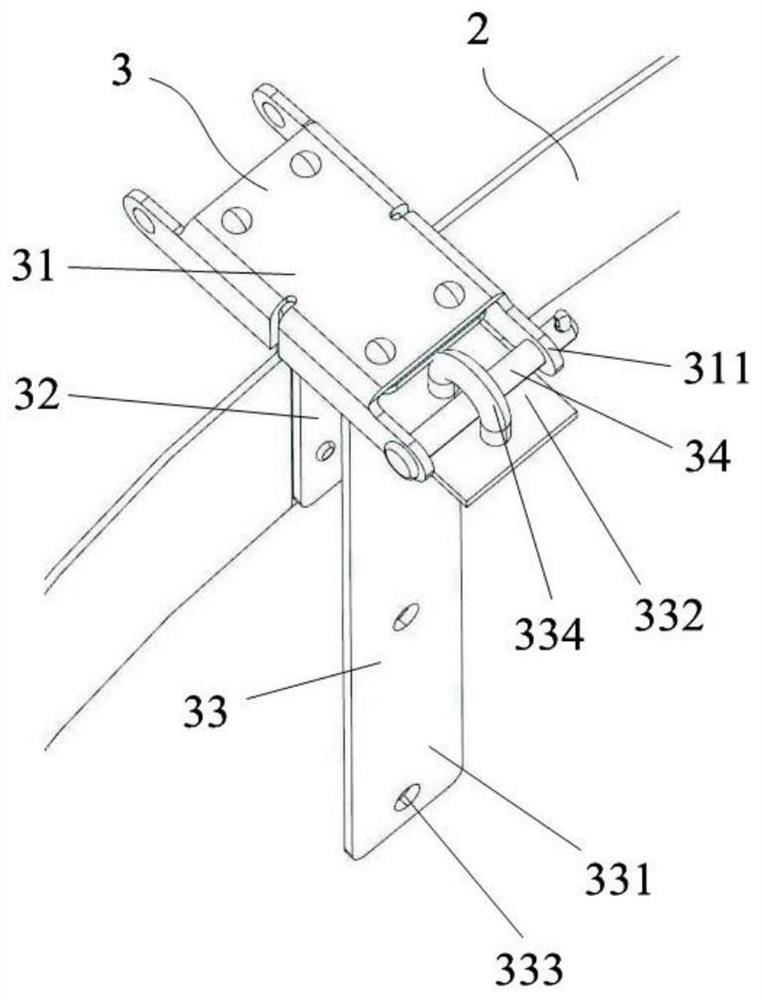

[0026] figure 1 and figure 2 The structures of the cabling frame 100 for the vehicle end of a rail vehicle according to the present invention are respectively shown from different viewing angles. Such as figure 1 As shown, the cable rack 100 includes a mounting base 1, an elastic plate 2, multiple clamp assemblies 3 and multiple engaging parts (not shown). There are two mounting bases 1 for being installed on the vehicle end. The elastic plate 2 is configured in an arc shape, and the two circumferential ends of the elastic plate 2 are installed on the two mounting bases 1 respectively. A plurality of wire clip assemblies 3 are distributed along the extension of the elastic board 1 and installed on the elastic board 2 at even intervals. A plurality of engaging parts can be fitly connected with the mounting base 1 and the wire clamp assembly 3, so that a plurality of engagements are respectively fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com