Efficient full-automatic punching machine

A fully automatic, stamping machine technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of low degree of automation, low work efficiency, unable to meet market needs, etc., to improve processing efficiency, improve positioning accuracy, The effect of preventing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

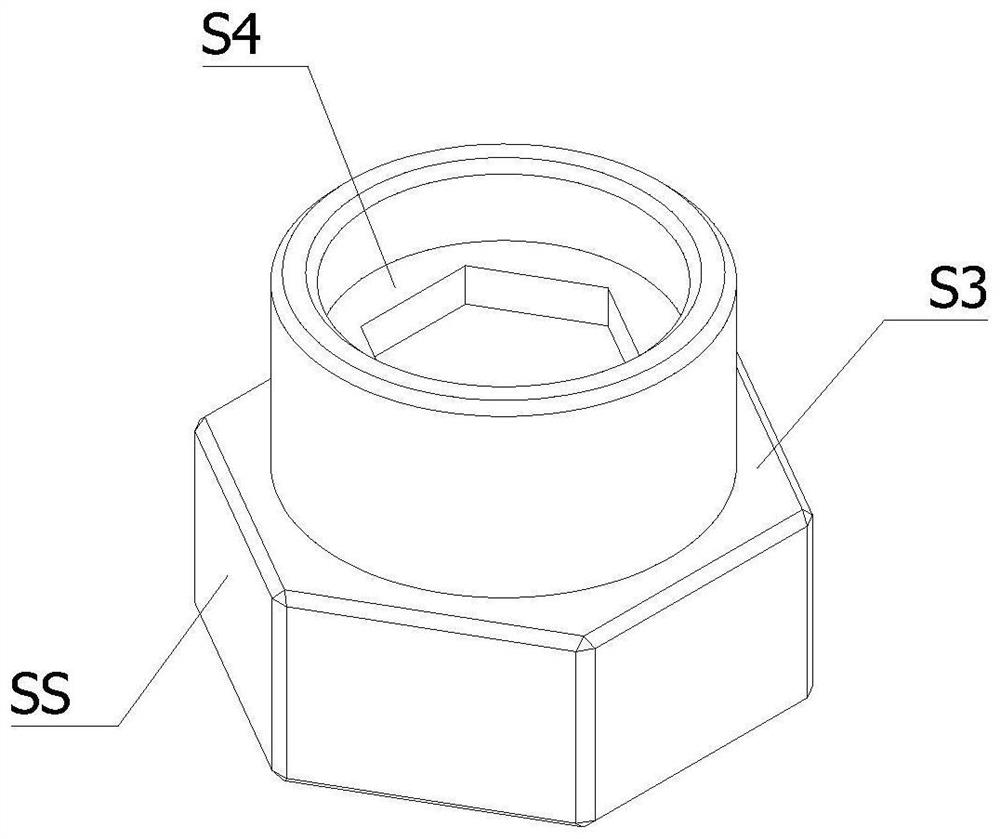

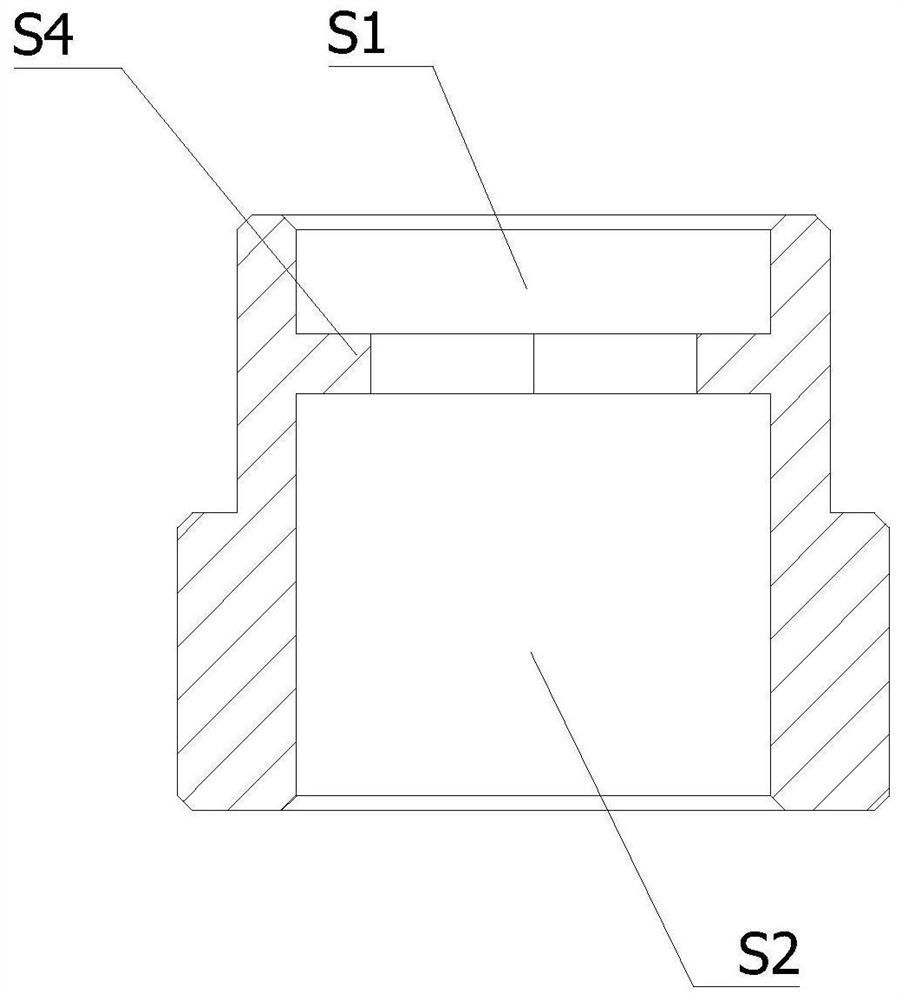

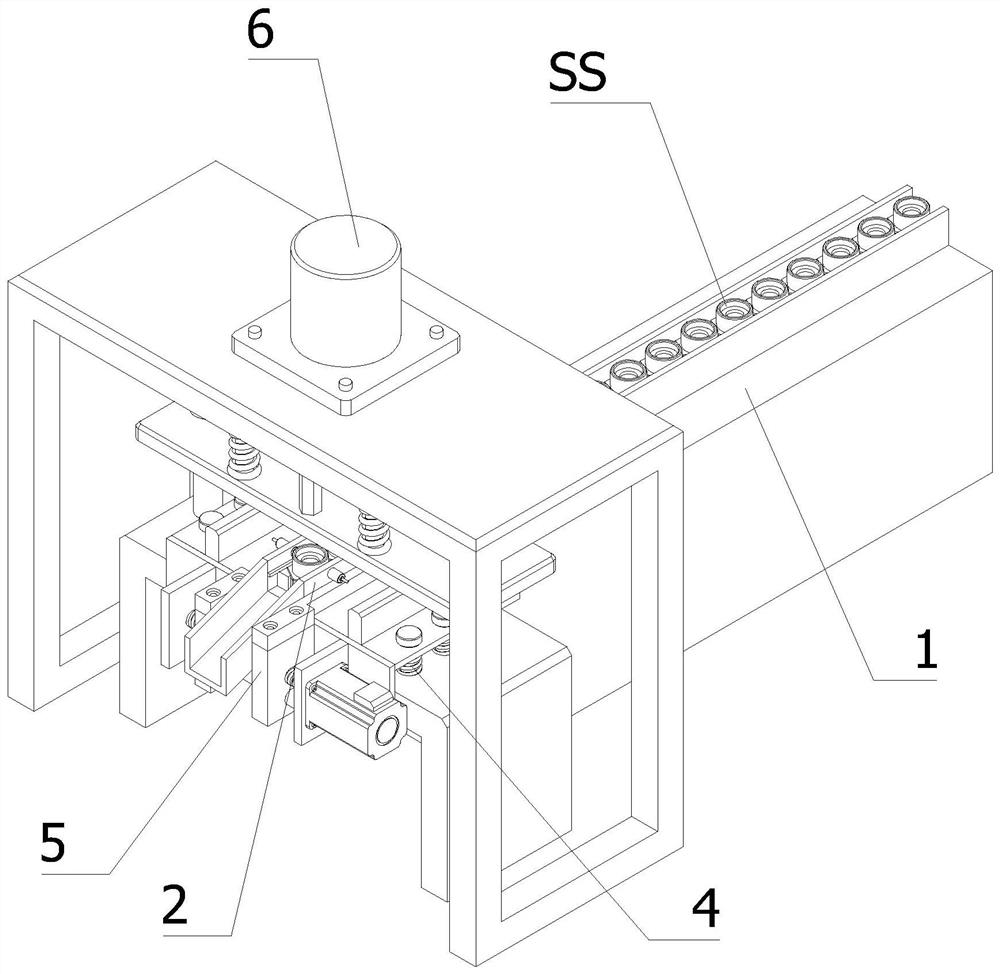

[0066] In order to solve the technical problem of how to efficiently complete the automatic stamping of the pipe connector SS to form the hexagonal through hole, such as Figure 1-11 As shown, the following technical solutions are provided:

[0067] A high-efficiency fully automatic stamping machine, including:

[0068] frame;

[0069] An automatic feeding device 1, the automatic feeding device 1 is installed on the frame, and the automatic feeding device 1 includes a vibrating plate and a feeding track 1a;

[0070] Also includes:

[0071] Movable track 2, movable track 2 can vertically lift and set, and movable track 2 is docked with the discharge end of feeding track 1a when it is located at the highes...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap