Device for producing variable-diameter round bar material and machining method

A technology of variable diameter and driving device, which is applied in the direction of feeding device, metal processing equipment, metal processing machinery parts, etc., to achieve the effect of simple and fast operation, high precision and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

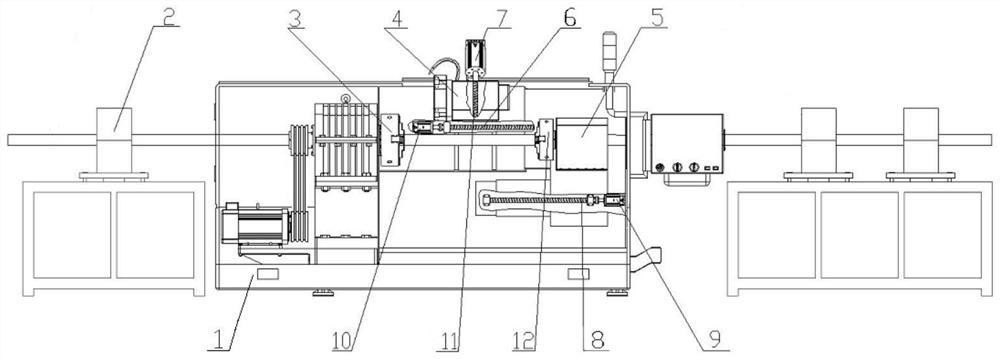

[0017] A device for producing variable-diameter round rod materials, including an equipment base 1 and fixed brackets 2 arranged on both sides of the equipment collective, and a front chuck 3 is arranged on the equipment base 1;

[0018] The right side of the equipment base 1 is provided with an automatic tailstock 5, and the bottom of the automatic tailstock 5 is provided with a driving device A for driving it to move;

[0019] The driving device A includes an automatic tailstock screw 8 that is rotatably connected to the bottom of the automatic tailstock 5, one end of the automatic tailstock screw 8 is rotatably connected to the equipment base 1, and the other end is matched with an automatic tailstock servo motor 9;

[0020] The top of the equipment base 1 is provided with a turning tool holder 4, and the bottom of the turning tool holder 4 is provided with a driving device B for driving it to move;

[0021] The driving device B includes a platen that is horizontally slidab...

Embodiment 2

[0025] A processing method for producing a variable-diameter round rod material, comprising the following steps:

[0026] Step 1. The first section of bar processing: first clamped by the front chuck 3, the bar is placed on the front chuck 3, the rear chuck 12 at the front end of the automatic tailstock 5 clamps the bar, and the automatic tailstock servo motor 9 drives The rotation of the automatic tailstock screw 8 drives the automatic tailstock 5 to return to the designated position, and the tool on the turning tool holder 4 turns the bar. The rotation of the seat screw 8 drives the automatic tailstock 5 to advance, and stops after feeding to the turning end of the bar. The rear chuck 12 executes the clamping command, forming a state where the front chuck 3 and the rear chuck 12 clamp the two ends of the bar;

[0027] Step 2. Processing of other sections of bar material: the program controls the turning tool holder 4 to repeatedly execute the work of setting the length and d...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap