Tool clamp for automobile part machining

A technology of auto parts and clamping, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of unfixable, fixed misalignment, low fixing efficiency, etc., and achieve the effect of ensuring the firmness of reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

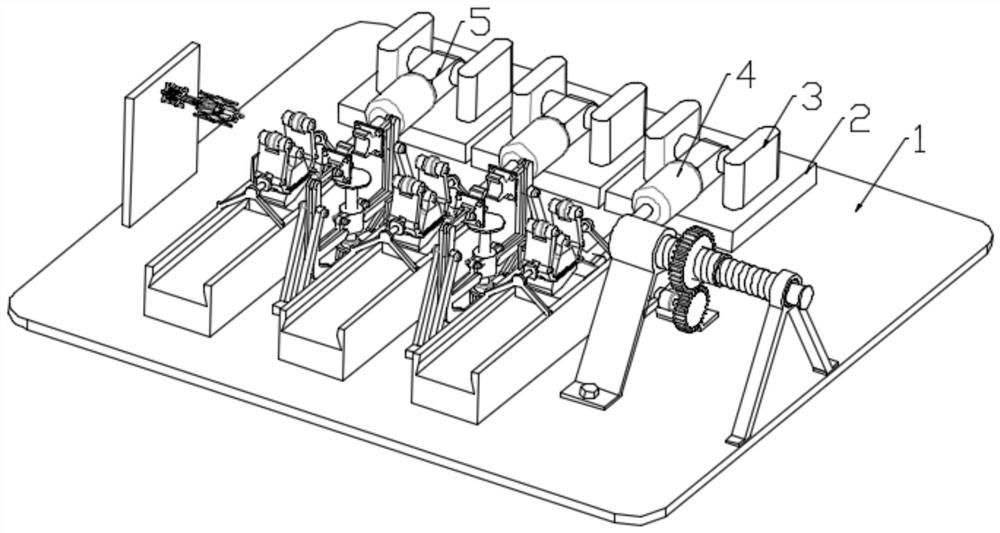

[0030] see figure 1 , in an embodiment of the present invention, the tooling fixture for processing auto parts includes:

[0031] A workbench 1, a fixed plate 2 is installed on the workbench 1, and a base 3 is installed on the fixed plate 2;

[0032] The connecting column 5 is rotatably connected between the bases 3, and the middle part of the connecting column 5 is equipped with a No. 1 telescopic output member 4;

[0033] The clamping and fixing assembly is installed on the workbench 1 and is used for multi-directional clamping and fixing of auto parts;

[0034] The conveying mechanism is installed on the workbench 1, and is used to convey the auto parts to the clamping and fixing assembly for fixing;

[0035] Wherein, the clamping and fixing assembly includes:

[0036] The No. 1 clamping mechanism is connected with the telescopic end of the No. 1 telescopic output member 4, and is used to realize the lateral fixation of auto parts;

[0037] The No. 2 clamping mechanism ...

Embodiment 2

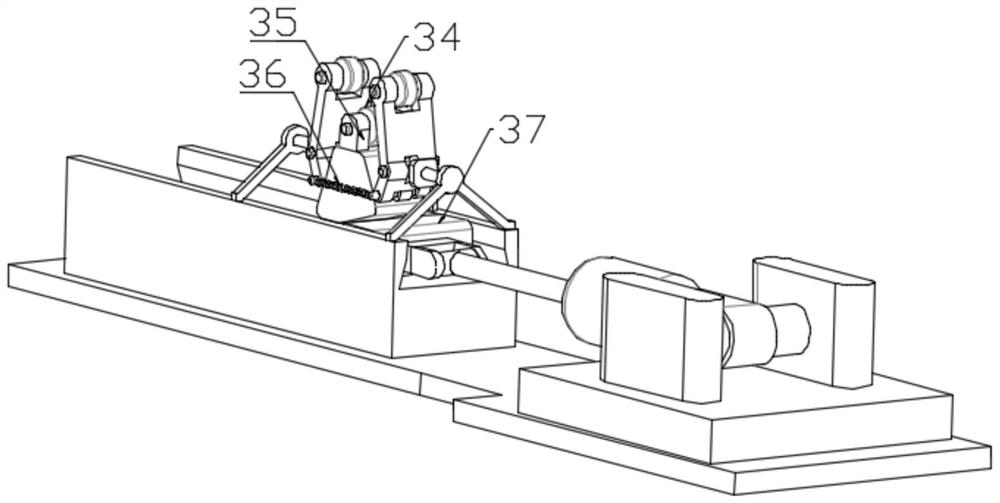

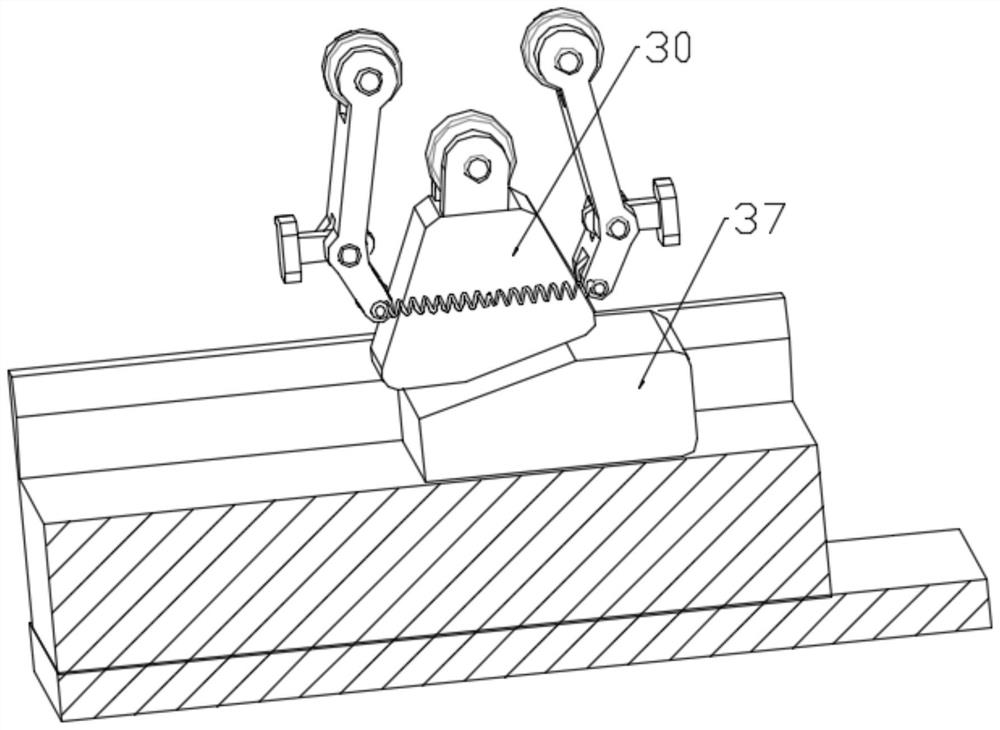

[0047] see figure 1 and Figure 5 , in the embodiment of the present invention, the No. 2 clamping mechanism includes:

[0048] The turret 15 is installed on the workbench 1;

[0049] The No. 2 telescopic output part 19 is located on the workbench 1 and is located between the turrets 15. The telescopic end of the No. 2 telescopic output part 19 is connected with a sliding rod 22, and one end of the sliding rod 22 is equipped with a limit plate. 23. The limit plate 23 is used to support the auto parts;

[0050] A sliding sleeve 21, the sliding sleeve is arranged on the sliding rod 22, and the sliding sleeve 21 is rotatably connected with a vertical rod 26;

[0051] The push rod 20 is connected with the vertical rod 26, and one end of the push rod 20 is fixedly equipped with a rotating rod 16, and the rotating rod 16 is connected with the turret 15;

[0052] Telescopic pump 18, the rotating rod 16 is connected to provide power for the rotation of the rotating rod 16;

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com