Waste discharge system for die-cutting piece coarse product with holes

A technology for die-cut parts and rough products, which is applied in the field of waste discharge system for die-cut parts and rough products, which can solve the problems of reduced efficiency, difficult discharge, fast return viscosity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

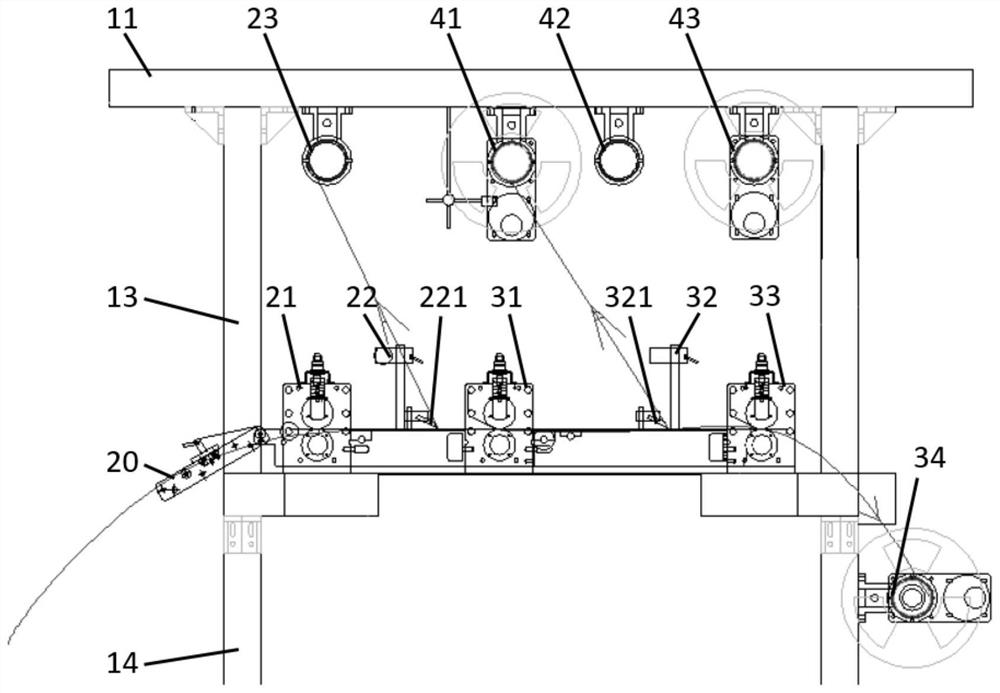

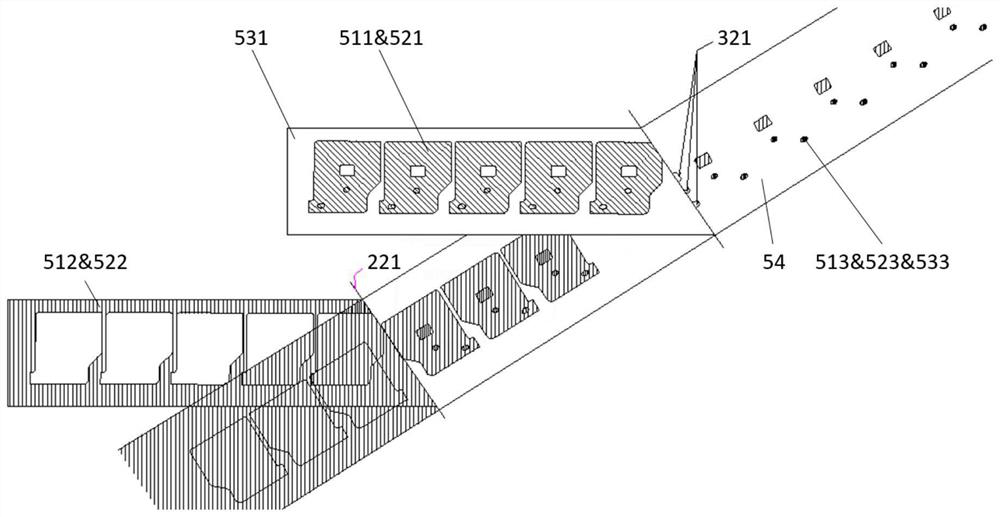

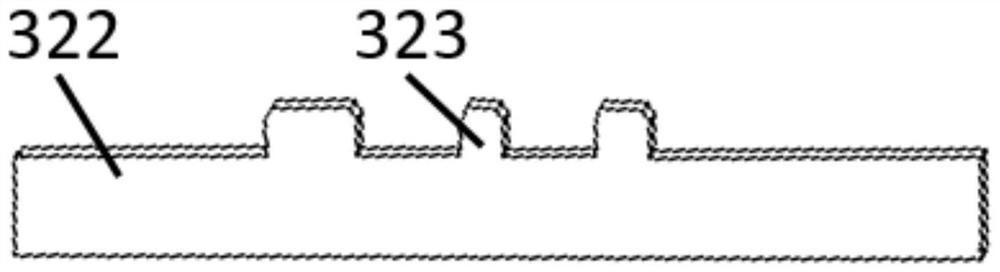

[0032] A waste removal system for rough product of die-cut parts with holes, such as figure 1 As shown, the system includes an outer frame, a contour waste discharge unit, a hole waste discharge unit and a material receiving unit. The contour waste discharge unit, the hole waste discharge unit and the material collection unit are all fixed on the outer frame. After the waste discharge unit, the contour waste is discharged to form a primary material belt. After passing through the hole waste discharge unit, the hole waste is discharged to form a finished die-cut piece on the receiving unit.

[0033] Such as figure 1 As shown, the outer frame includes a top beam 11, a partition 12, at least two upper columns 13 and at least two lower columns 14, and the upper columns 13 and the lower columns 14 are respectively connected above and below the partition 12, and the top beam 11 and the upper Angle steel riveting is used between the columns 13, and angle steel riveting is used bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com