Material piling system for uniformly mixed material piles in iron and steel plant

An iron and steel plant and mixing technology, which is applied in the field of the stacking system of the mixing and homogenizing material pile in the iron and steel plant, can solve the problem of not being able to reclaim and stack the same pile of raw materials, and achieve the effect of ensuring continuity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

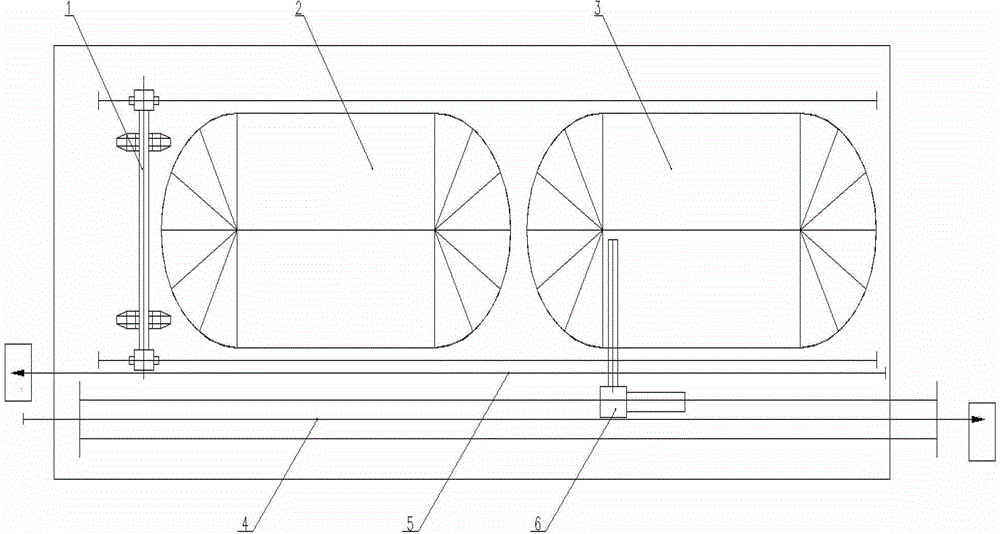

[0017] see figure 1 , the prior art mixing stockyard is generally single-span two-pile type, that is to say, there are two stockpile, respectively a mixing stockpile 2 and another mixing stockpile 3, and the material layer is generally 400 ~700 layers or so, when working, the mixed ore configured by the batching tank is transported by the stacking belt conveyor 4 to the mixing stacker 6 for stacking operations, which is the process of forming another mixed stockpile 3 , Simultaneously, the mixing reclaimer 1 can only carry out reclaiming on a mixing pile 2, and the mixing ore is conveyed out through the reclaiming belt conveyor 5.

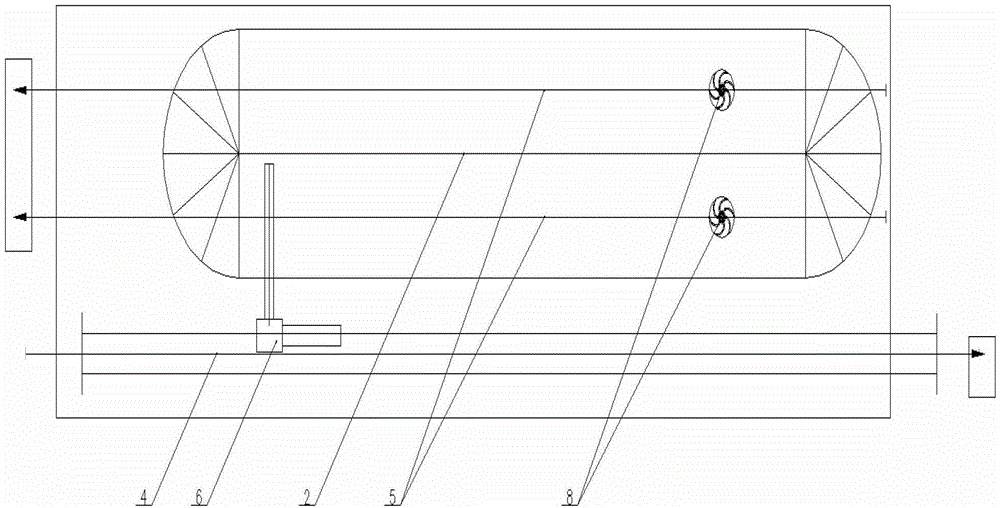

[0018] see figure 2 , the embodiment of the present invention provides a stacking and retrieving system for the mixed material pile in the iron and steel plant, the system includes a stacking conveying equipment, a stacking At the bottom of the stack, the reclaiming and conveying equipment is located at the bottom of the reclaiming equipment, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com