Environment-friendly filter material for filtering paint mist and preparation method thereof

An environmental protection and filter material technology, applied in filtration and separation, membrane filters, separation methods, etc., can solve the problems of re-pollution of water sources and high maintenance costs, and achieve the effect of reducing the number of replacements, improving the outflow speed, and reducing equipment maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1, a kind of preparation method of filtering paint mist environmental protection filter material, comprises the following steps:

[0048] S1: Prepare materials, use 4Kg low melting point fiber and 5Kg3D fine fiber as raw material A for making the basic filter layer, 3Kg low melting point fiber, 3Kg30D fiber and 1Kg 3D fiber as raw material B for the embossed filter layer;

[0049] S2: Material molding, put two parts of raw material A into the first opener and the third opener respectively, and add one part of raw material B into the second opener for uniform mixing and removal of impurities;

[0050] S3: Storing materials, transporting two parts of raw material A and one part of raw material B to the first, third and second cotton mixing boxes respectively through the wind force of the wind turbine for mixing;

[0051] S4: carding processing, two parts of raw material A and one part of raw material B are transported to corresponding first, third and second ca...

Embodiment 2

[0059] Embodiment 2, a kind of preparation method of filtering paint mist environmental protection filter material, comprises the following steps:

[0060] S1: Prepare materials, use 5Kg low melting point fiber and 6Kg3D fine fiber as raw material A for making the basic filter layer, 5Kg low melting point fiber, 6Kg30D fiber and 4Kg 3D fiber as raw material B for the embossed filter layer;

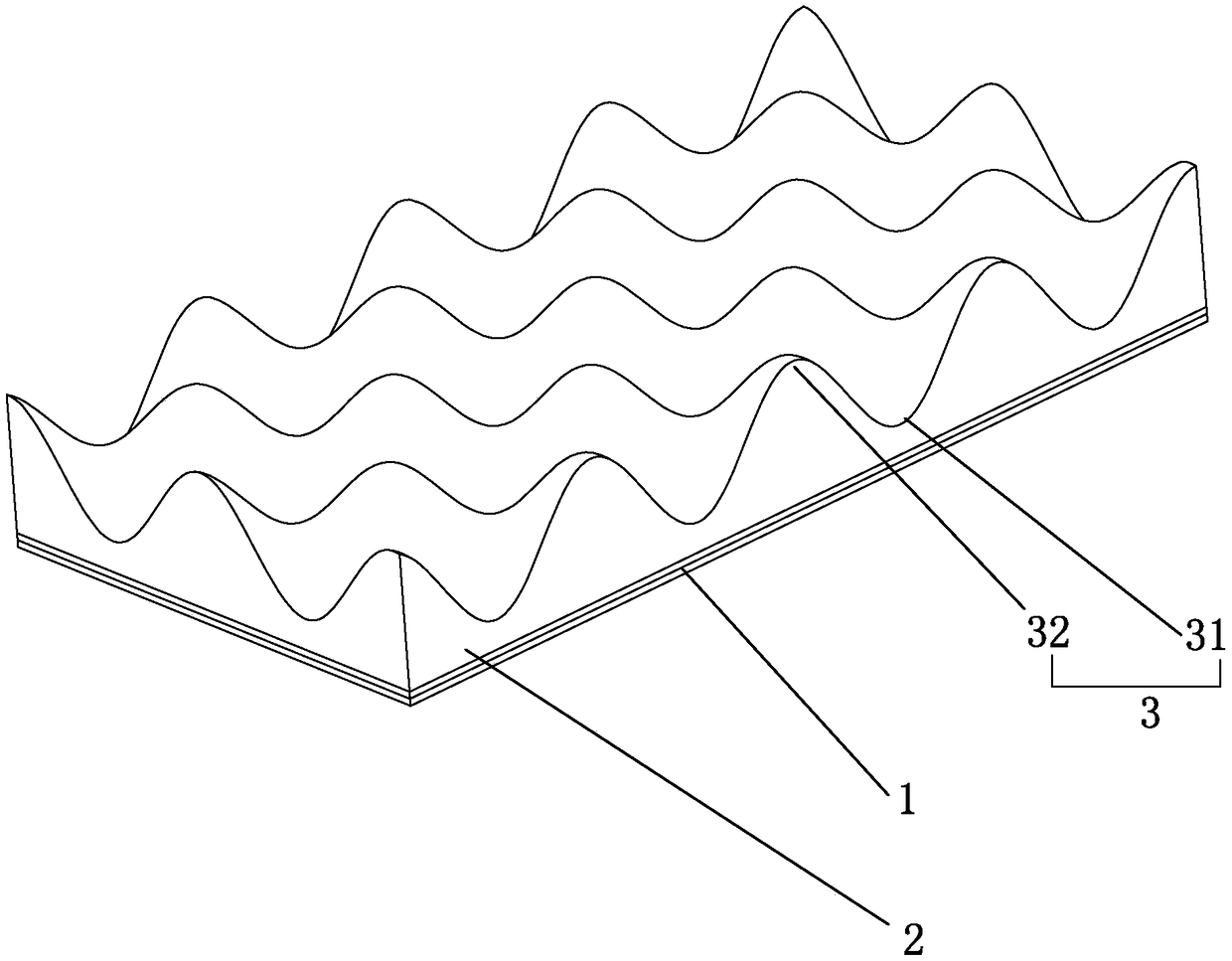

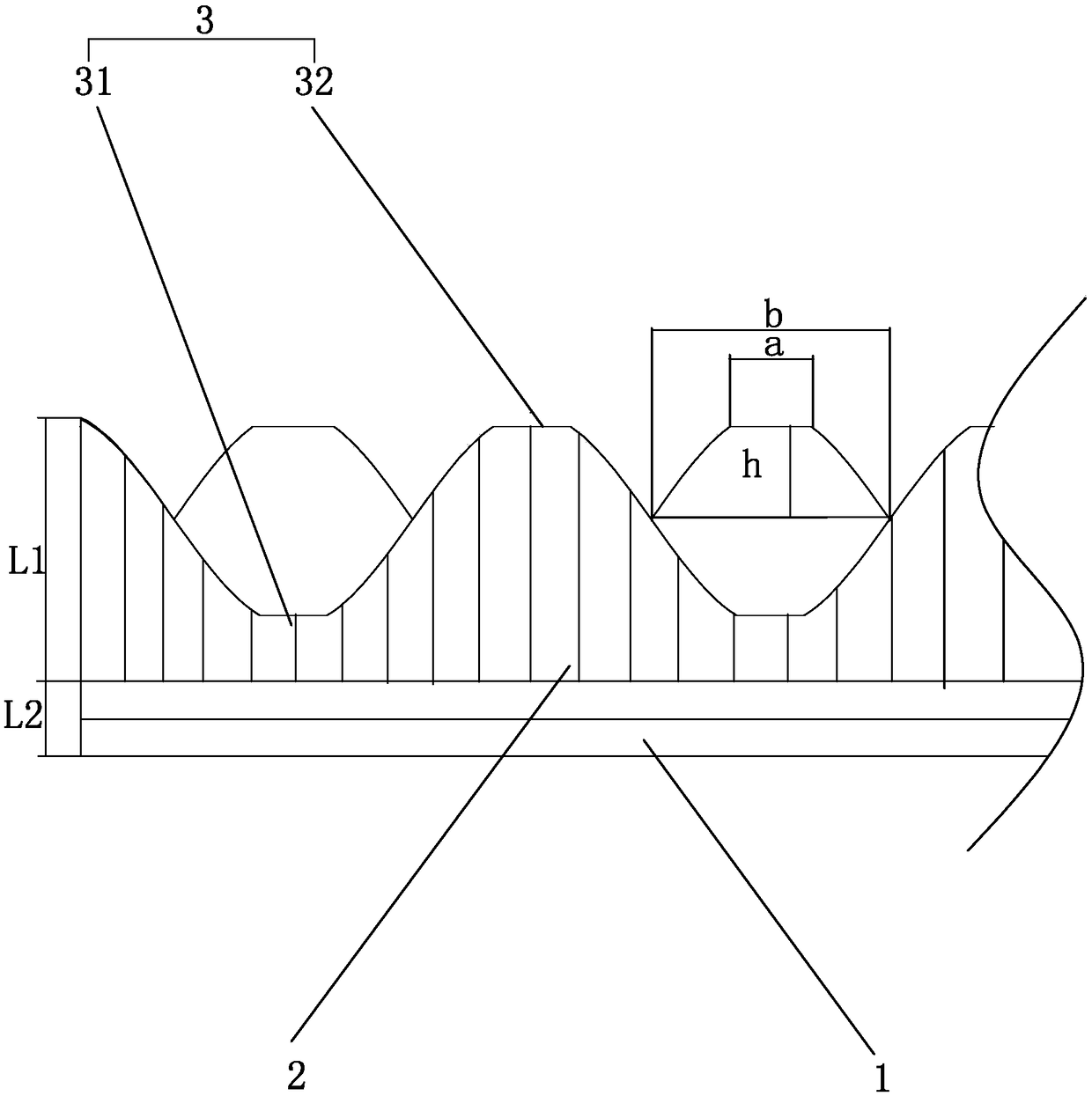

[0061] S6: Lay the fiber web C evenly on the bottom curtain of the web-laying machine through a flat-laying machine to form a 3cm-thick flat-type fiber layer 1, and then lay the fiber web D to a height through the vertical web-laying machine The vertical fiber web layer 2 with a thickness of 7 cm is first placed on the bottom layer of the flat fiber layer 1 made of fiber web C through the bottom curtain, and then the vertical fiber web layer 2 made of fiber web D is placed on the flat surface. On the top of the paved fiber layer 1, the fiber web E is evenly laid out with a 3cm thick flat f...

Embodiment 3

[0063] Embodiment 3, a kind of preparation method of filtering paint mist environmental protection filter material, comprises the following steps:

[0064] S1: Prepare materials, use 4.5Kg low melting point fiber and 5.5Kg3D fine fiber as raw material A for making the basic filter layer, 4Kg low melting point fiber, 4.5Kg30D fiber and 2.5Kg 3D fiber as raw material B for the embossed filter layer;

[0065] S6: Lay the fiber web C evenly on the bottom curtain of the web-laying machine through a flat-laying machine to form a 2cm-thick flat-laying fiber layer 1, and then lay the fiber web D to a height through the vertical web-laying machine For a 6cm thick vertical fiber web layer 2, first place the flat fiber web layer 1 made of fiber web C on the bottom layer through the bottom curtain, and then place the vertical fiber web layer 2 made of fiber web D on the flat surface. On the top of the paved fiber layer 1, the fiber web E is evenly laid out with a 2cm thick flat fiber laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com