Semi-automatic chain saw capable of reducing noise

A semi-automatic, chain saw technology, used in chainsaws, sawing equipment, wood processing appliances, etc., can solve the problems of reducing the practicability of the chain saw, reducing the service life of the saw teeth, and high noise, and increasing the automatic judgment. effect, ensure normal use, solve the effect of lack of lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

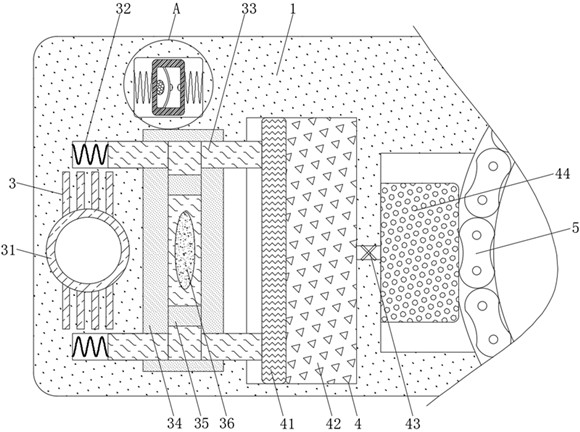

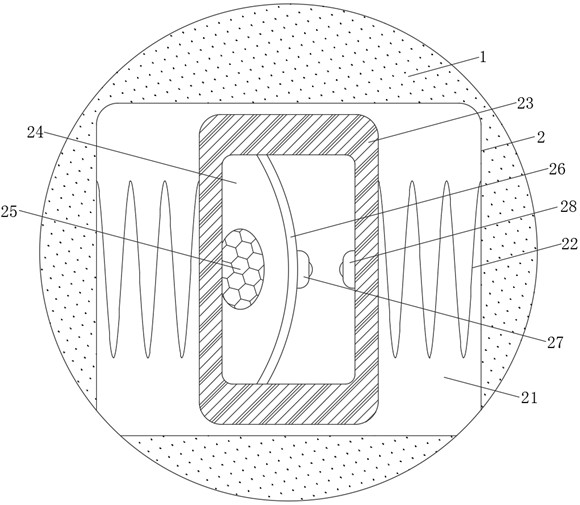

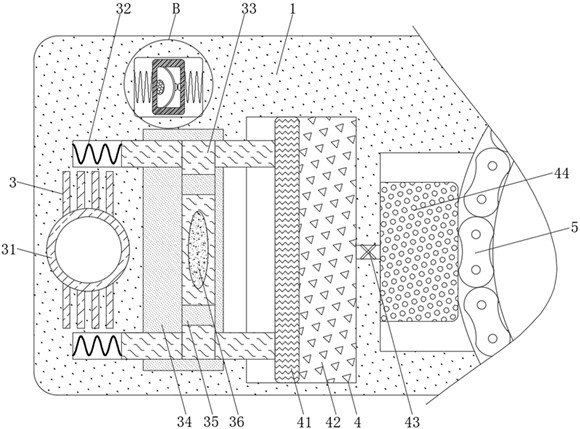

[0023] see Figure 1-4 , a noise reduction semi-automatic chainsaw, comprising a housing 1, the inner wall of the top of the housing 1 is fixedly connected with a detection mechanism 2, the detection mechanism 2 plays the role of judging whether the chain saw is in a state of lack of lubricating oil, the housing 1 The inner wall of the housing 1 is fixedly connected with an adding mechanism 3 close to the bottom of the detection mechanism 2, and the adding mechanism 3 plays the role of adding lubricating oil. The lubricating mechanism 4 plays the role of lubricating the sawtooth 5 , and the right side of the housing 1 is fixedly connected with the sawtooth 5 slidingly connected to the right side of the lubricating mechanism 4 .

[0024] The adding mechanism 3 includes an electromagnet 31, the inner wall of the housing 1 is fixedly connected with the electromagnet 31, the magnetism generated on the right side of the electromagnet 31 is the same as the magnetism on the left side...

Embodiment 2

[0027] see Figure 1-4 , a noise reduction semi-automatic chainsaw, comprising a housing 1, the inner wall of the top of the housing 1 is fixedly connected with a detection mechanism 2, the detection mechanism 2 plays the role of judging whether the chain saw is in a state of lack of lubricating oil, the housing 1 The inner wall of the housing 1 is fixedly connected with an adding mechanism 3 close to the bottom of the detection mechanism 2, and the adding mechanism 3 plays the role of adding lubricating oil. The lubricating mechanism 4 plays the role of lubricating the sawtooth 5 , and the right side of the housing 1 is fixedly connected with the sawtooth 5 slidingly connected to the right side of the lubricating mechanism 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com