Automatic yarn cutting and splicing method suitable for winding yarns and yarn cutting and splicing device suitable for method

A yarn-wound, automatic technology, applied in the cutting of textile materials, textiles and papermaking, etc., can solve the problems of low work efficiency, safety and hidden dangers of manual yarn splicing, improve work efficiency, and realize automatic yarn splicing and yarn cutting. effect of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

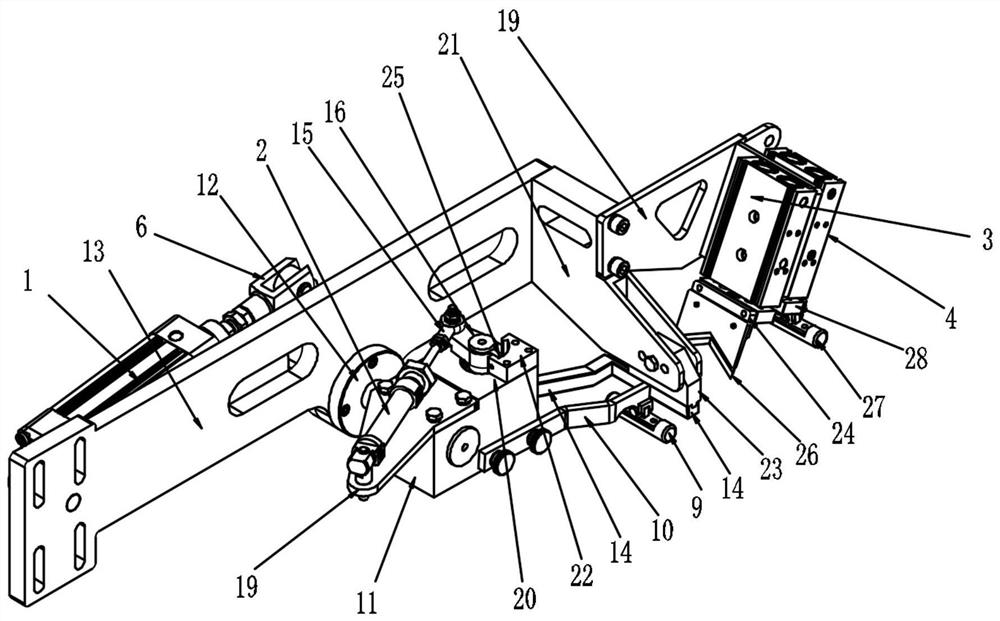

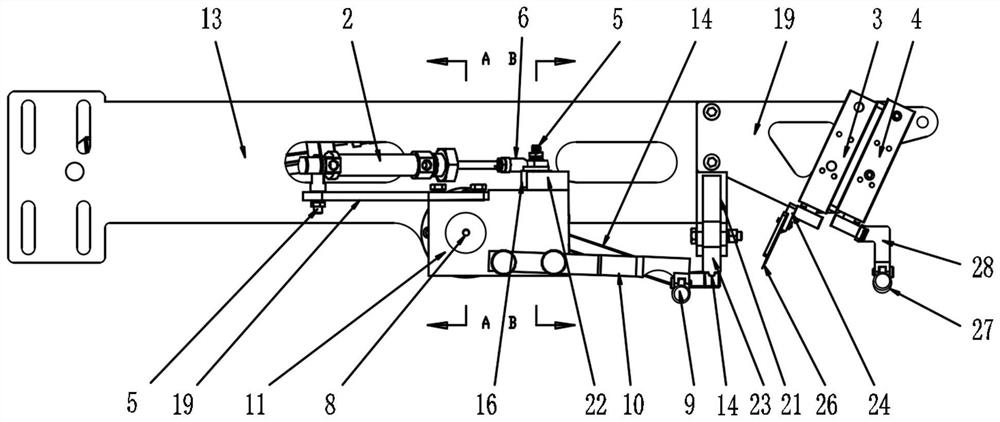

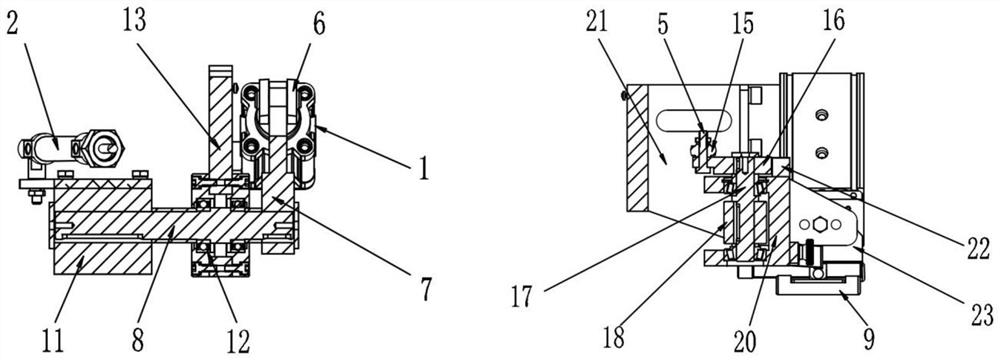

[0043] The first step: before the glass fiber yarn is wound, the winding yarn 30 passes through the lower surface of the first pressure roller 9, between the clamping rod 14 and the pressing block 23 in sequence, and the yarn clamping rod 14 and the pressing block 23 are in a closed state, as Figure 4 shown;

[0044] Step 2: Install the winding mold 29, fix the yarn splicing device on the winding nozzle, and the outstretching arm drives the winding nozzle to move the yarn cutting device synchronously, and the extending arm takes the first pressure roller 9 to the top of the winding mold 29, and starts The first cylinder 1, the stroke of the telescopic rod at the front end of the first cylinder 1 is extended, and the first transmission rod 7 hinged by the first joint 6 by the first cylinder 1 drives the rotating shaft 8, and then drives the rotating seat 11 to rotate and press down, and it is fixed at this time The pressing rod 10 and the clamping rod 14 on the rotating seat 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com