Electric vehicle four-wheel-drive torque distribution method and system and vehicle

A technology for torque distribution and electric vehicles, which is applied in electric vehicles, vehicle components, motors, etc., can solve problems such as poor power performance, poor driving comfort for users, impact, etc., and achieve the goal of improving driving comfort and power performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0027] The present invention will be described below with reference to the drawings.

[0028] In this embodiment, four-wheel drive torque distribution for an electric vehicle, comprising the steps of:

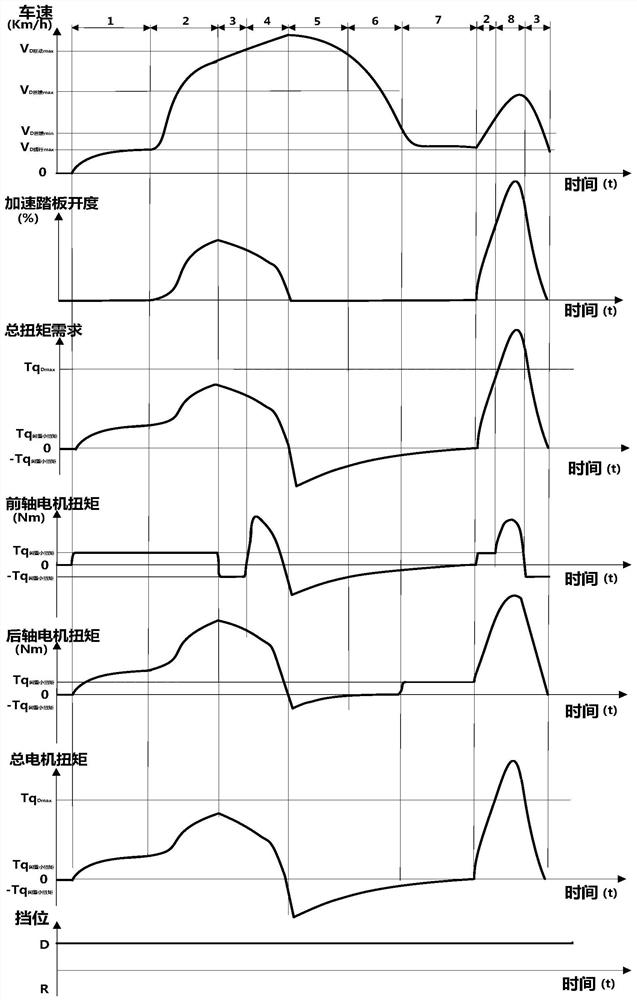

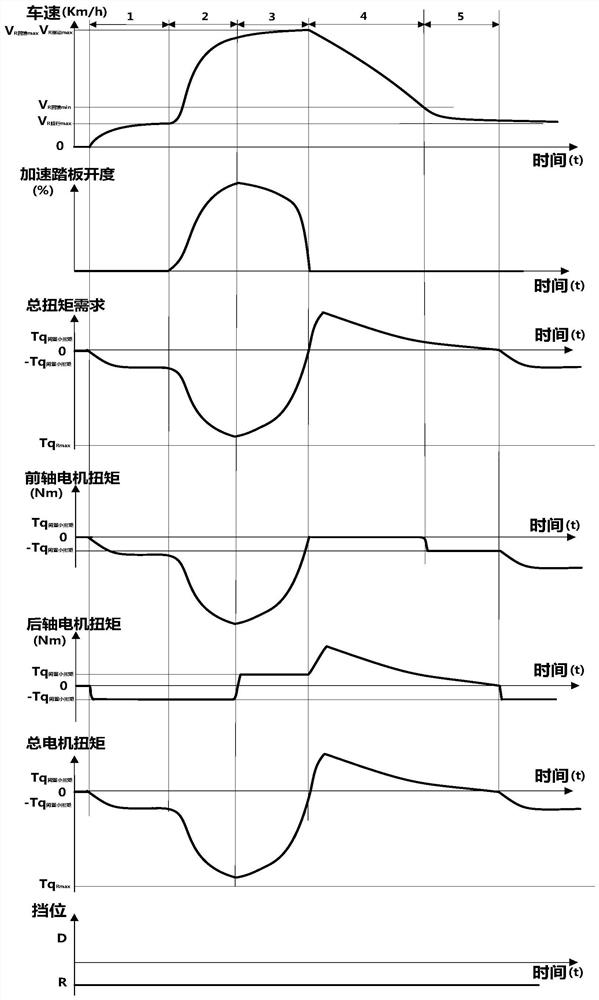

[0029] like figure 1 As shown, S1 forward gear driving cycle:

[0030] Stage 1: forward gear when creep driving conditions, the vehicle speed is ≤V D蠕行max And the total torque demand is below Tq Dmax When, the motor is independently controlled rear axle creep torque output control "idle" is not the output torque of the motor of the front axle load of the idle forward low torque Tq 闲置小扭矩 .

[0031] Stage 2: When the vehicle is in forward gear speed driving condition, V D蠕行max D驱动max The total torque demand ≤Tq Dmax And when it is determined that the vehicle acceleration value unchanged or increased acceleration value, the rear axle motor in response to the control demand total torque output independent drive torque control "idle" is not the output torque of the motor of the front ax...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap