Anchor bolt thermal shrinkage production line

A production line and heat-shrinking technology, applied in the direction of wrapping paper shrinkage, special packaging objects, tubular objects, etc., can solve the problems of low production efficiency, high labor intensity of workers, etc., to facilitate centralized transportation, reduce labor intensity and labor costs, The effect of facilitating overall packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

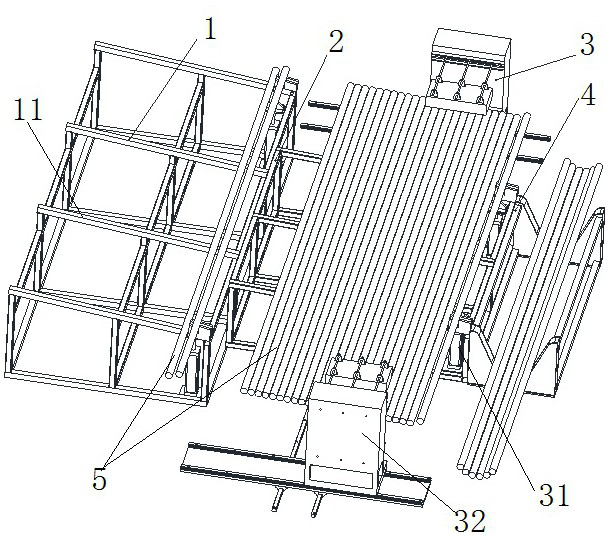

[0047] Such as Figure 1 to Figure 7 As shown, the anchor bolt heat shrink production line in this embodiment as a whole includes a feeding unit 1, a heat shrink unit 3 and a material receiving unit 4, and the feeding unit 1, heat shrink unit 3 and material receiving unit 4 are arranged in sequence along the front and rear directions The feeding unit 1 transfers the anchor bolts 5 one by one to the heat shrink unit 3 one by one. The heat shrink unit 3 is used to heat the heat shrink tubes 52 on both sides of the anchor bolt 5. After heating, the material receiving unit 4 receives the heat shrink to complete Anchor bolt 5.

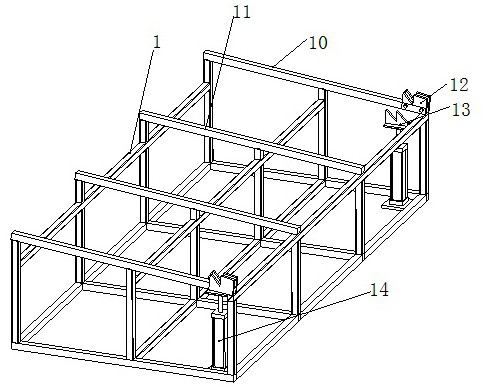

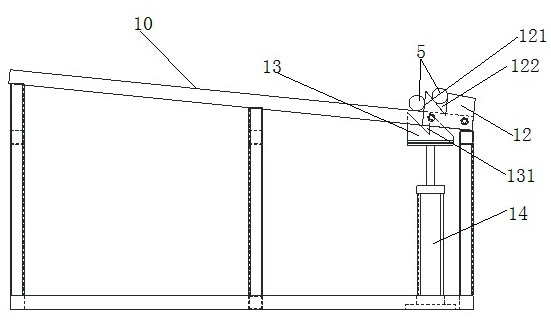

[0048] Specifically, the structure of the feeding unit 1 is as follows figure 1 , figure 2 and image 3 As shown, the loading unit 1 is used to transport the anchor bolt 5 to the heat shrinking platform 31 of the heat shrinking unit 3, and the loading unit 1 includes a loading platform, such as figure 2 As shown, the feeding platform is a frame struc...

specific Embodiment 2

[0063] The main difference between it and Embodiment 1 is that in Embodiment 1, the heaters on both sides move back and forth in the front and rear directions to realize the relative movement between the anchor bolt and the heater to complete shrinkage heating. In this embodiment, the heater is fixed in the front-to-back direction, and the heat-shrinkable support surface on the heat-shrink stand is arranged obliquely from front to back. The heating plate realizes heat shrinkage heating. It should be noted that this mode requires the unloading and lifting structure to continuously lift and transfer the anchor bolts to the receiving unit one by one. At this time, it is necessary to pay attention to the larger heating area of the heater. to ensure efficient heating. In this way, the self-gravity of the anchor bolt is used to roll backward, eliminating the need for power drive.

[0064] Of course, in other embodiments, the heater can also be moved back and forth along the fron...

specific Embodiment 3

[0066] The main difference between it and Embodiment 1 is that in Embodiment 1, the heater adopts a planar heating structure formed by upper and lower heating plates to heat the heat-shrinkable tube. In this embodiment, the planar heating structure includes an upper heating plate and a lower reflecting plate, and the emitting plate realizes heat reflection heating, so that the upper heating plate and the lower reflecting plate cooperate to realize shrinkage heating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com