Blending device for disinfectant production

A processing device and a matching technology are applied in the field of dispensing devices for disinfectant production, which can solve the problems of low work efficiency, difficulty in controlling the dosage of various solvents, etc., and achieve the effects of convenient operation, novel structure and ingenious conception.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to facilitate the understanding of the present invention, the specific embodiments of the present invention will be described below with reference to the accompanying drawings.

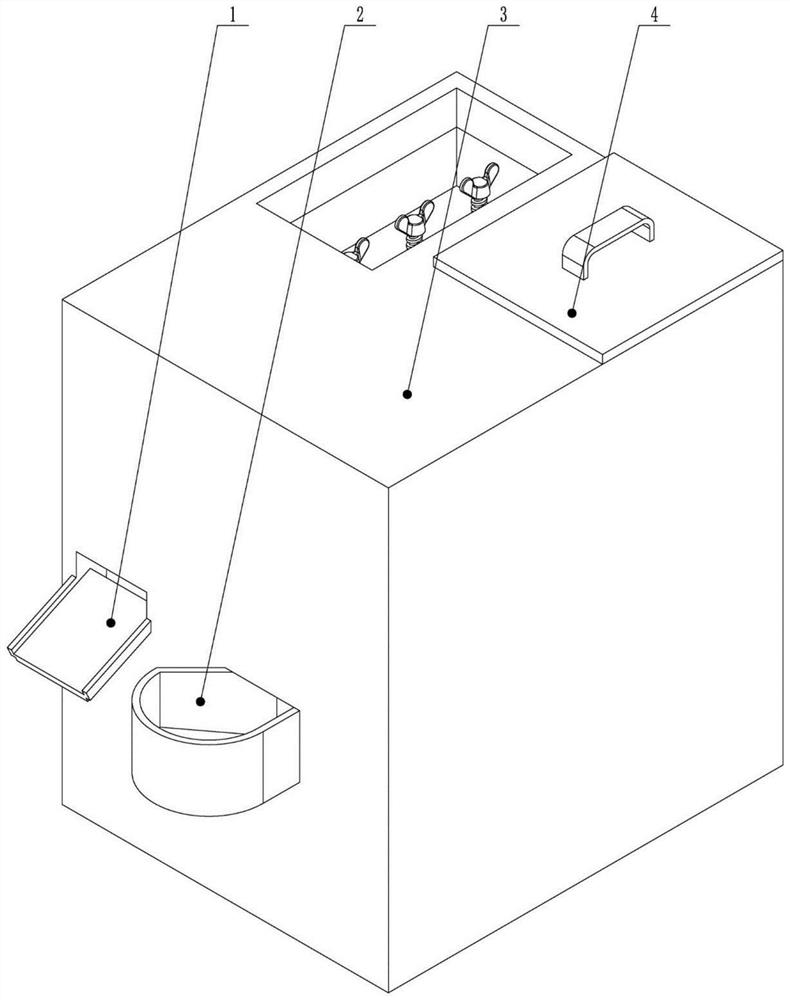

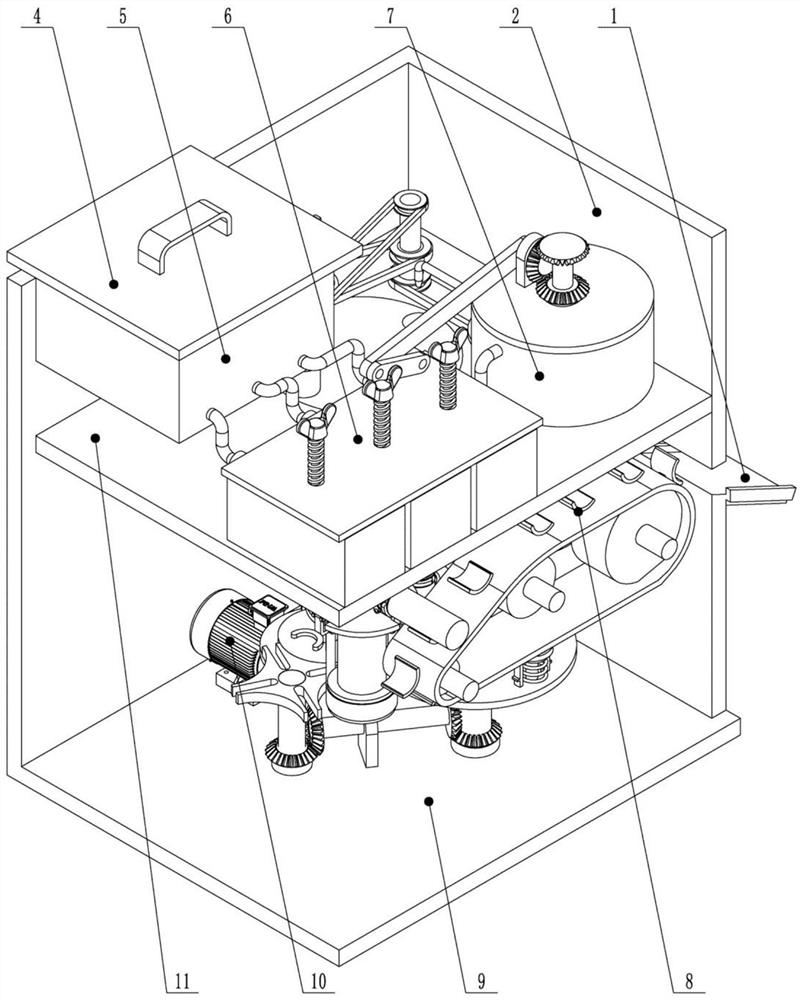

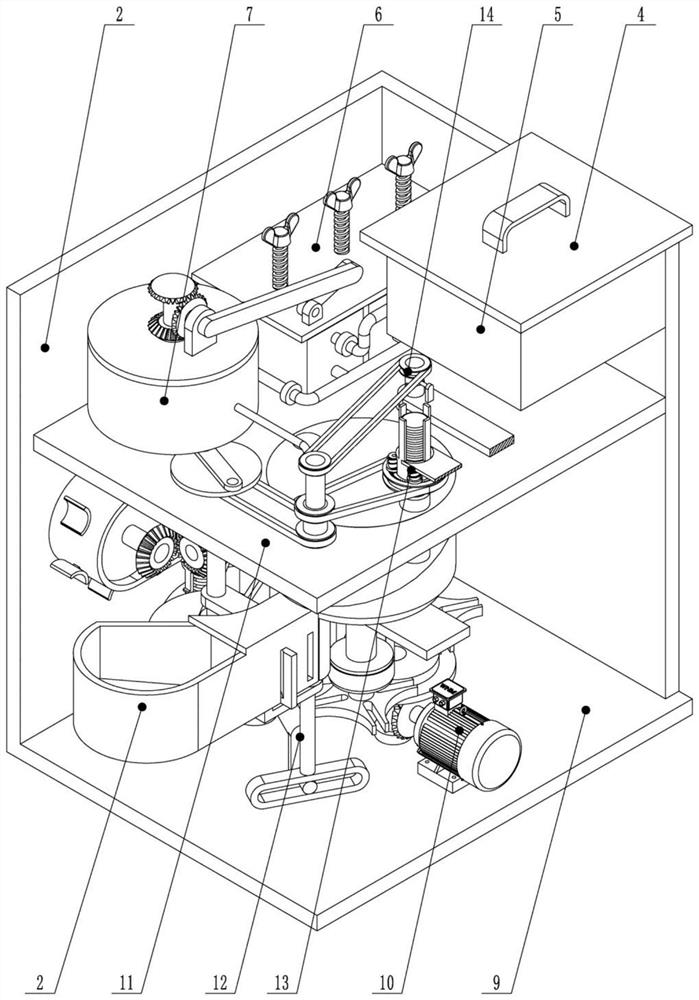

[0035] like figure 1 , figure 2 with image 3 As shown, a drug treatment apparatus for anesthetic drug, including the bottom plate 9, and the casing 3 is fixed to the bottom plate 9, and the casing 3 is fixed to the placement casing 2, and the placed cartridge 2 places a bottle body 51, shell. The body 3 is fixed to the curved fixing wheel 20, and the curved fixing wheel 20 is provided with a first circular hole and a second circular hole, and the first circular hole is fitted to the placement cartridge 2; the curved fixing wheel is rotated A plurality of circular holes are connected to the rotating disc 21, and the circular hole is fitted to the first circular hole and the second circular hole, and the bottom plate 9 is further rotated and connected to the second circular hole. Turn the ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com