Firewood-fired celeste glaze and firing method of celeste glaze Ru porcelain

A technology of celadon glaze and firewood firing, which is applied in the field of Ru porcelain glaze, can solve the problems of lack of jade texture, heavy feeling of glass of celadon glaze Ru porcelain, and can not meet the aesthetic appeal of Azure glaze Ru porcelain, so as to enhance the opacity feeling , reduce light perception, enhance the effect of glass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

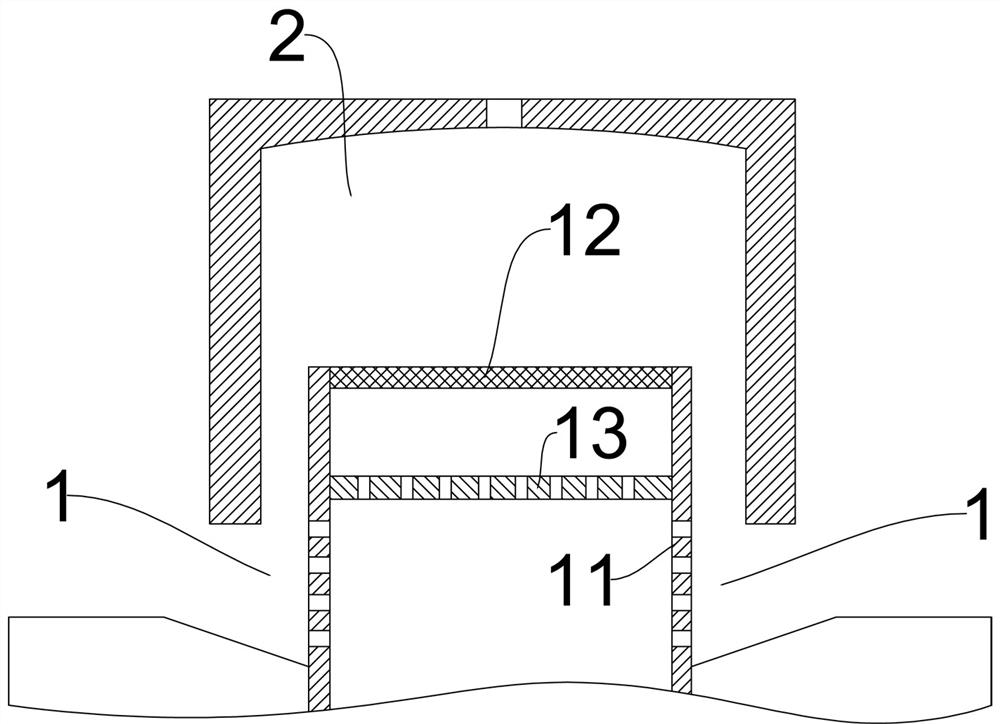

Image

Examples

Embodiment Construction

[0029] In the following, the present invention will be described in more detail through specific embodiments, so as to facilitate the understanding of the technical solution of the present invention, but it is not used to limit the protection scope of the present invention.

[0030] The firewood-fired celeste glaze of the present embodiment, by weight percentage, is made up of following raw material:

[0031] Quartz 16%, calcite 8%, plant ash 36%, potassium feldspar 10%, albite 10%, agate 8%, soda 12%. The main component of the agate stone used in this firewood azure glaze is SiO 2 .

[0032] The preparation method of described firewood azure glaze comprises the following contents:

[0033] Take azure glaze raw materials quartz, calcite, plant ash, potassium feldspar, albite, agate stone, soda stone, crush the raw materials respectively, weigh each raw material in proportion, ball mill, sieve, and the sieve balance of ten thousand hole sieve is 0.1 % to 0.3%, to remove iron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com