A building assembly type construction device

A construction device and assembly-type technology, which is applied in the direction of construction, building structure, and building material processing, can solve the problems of inconvenient use, low coordination, inability to reinforce and install operations, and facilitate support and erection operations. , easy to stretch the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

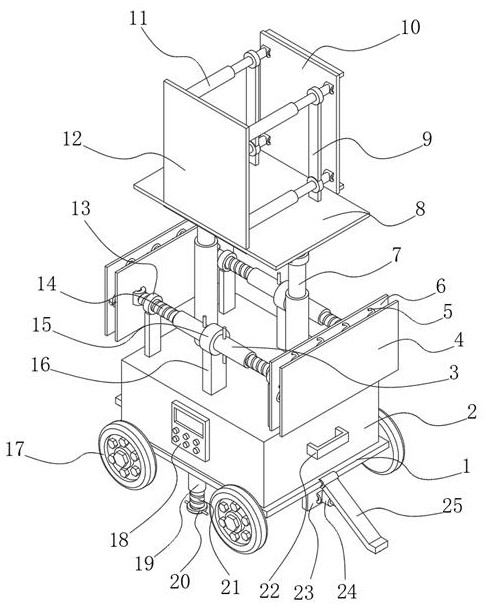

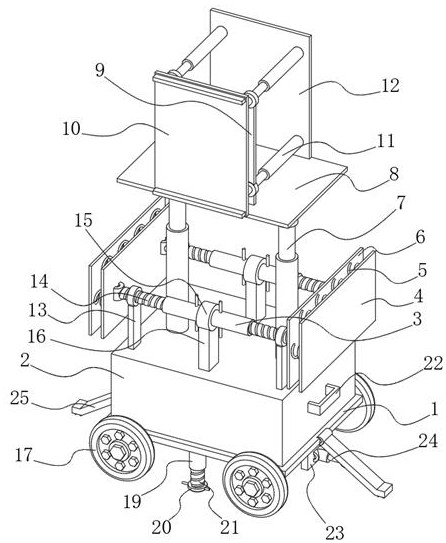

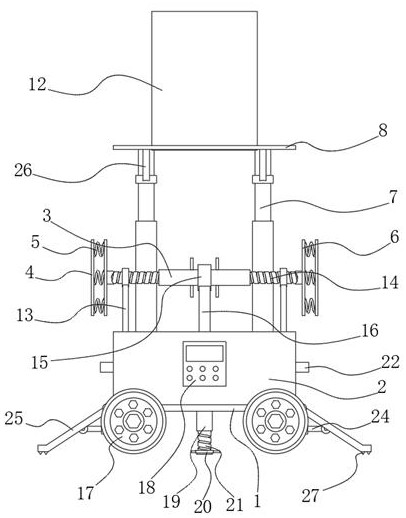

[0034] see Figure 1-6 As shown, the present invention provides a technical solution: a building assembly type construction device, comprising a base plate 1, the bottom of the base plate 1 is fixedly installed with two fixed thread cylinders 19, and the inside of the two fixed thread cylinders 19 are hinged with a second The threaded column 21, the bottom of the second threaded column 21 is fixedly installed with a ring plate 20, both sides of the bottom plate 1 are hinged with feet 25, and the bottom of the foot 25 away from the bottom of the bottom plate 1 is fixedly installed with a tooth claw 27, on both sides of the bottom of the bottom plate 1 The side plates 23 are fixedly installed, and the opposite sides of the side plates 23 are hinged with electric telescopic rods 24. The top of the bottom plate 1 is fixedly installed with the box 2, and the top of the box 2 is fixedly installed with two limit posts 16. A shaft seat 15 is fixedly installed at the top of each limit ...

Embodiment 2

[0037] like Figure 1-6 As shown, on the basis of the first embodiment, the present invention provides a technical solution: the bottom of the ring plate 20 is fixedly installed with a cushion, the two sides of the ring plate 20 are fixedly installed with rotating columns, and the output end of the electric telescopic rod 24 Hinged on one side of the foot 25.

[0038] In this embodiment, when the operator rotates the rotating column to drive the ring plate 20 to rotate, the rotating force is applied to the hinged connection between the second threaded column 21 and the fixed threaded cylinder 19 downward, so that the cushion at the bottom of the ring plate 20 contacts the ground, increasing friction At the same time, the telescoping of the electric telescopic rod 24 makes the feet 25 support on the ground, which can cooperate with the soft pad to increase the friction force, so that the equipment can stand more stably and is easy to assemble.

Embodiment 3

[0040] like Figure 1-6 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the top ends of the four movable struts 13 are all movably sleeved on the outside of the first threaded column 14, and the compression spring 5 is filled linearly. Evenly distributed on the opposite sides of the fixed plate 6 and the soft plate 4, a support plate 12 is fixedly installed on one side of the top of the top plate 8, and four hydraulic telescopic rods 11 are fixedly installed on one side of the support plate 12. The output end is hinged with the card plate 10, the outer side of the four hydraulic telescopic rods 11 is movably sleeved with a movable strut 9, the bottom of the movable strut 9 is fixedly installed on the top of the top plate 8, and one end of the two brackets 26 away from the top plate 8 is movable sleeve. Connected to the outside of the hydraulic telescopic column 7.

[0041] In this embodiment, the movable strut 13 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com