Vertical shaft wind driven generator and distributed energy storage station device

A wind turbine and vertical shaft technology, which is applied to wind turbines and devices that convert solar radiation into useful energy, wind turbines, and wind turbine combinations, etc., can solve the problems of large influence of wind direction and low fan efficiency, and improve power generation efficiency. , the effect of improving rotor rotation efficiency, enhancing layout breadth and practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

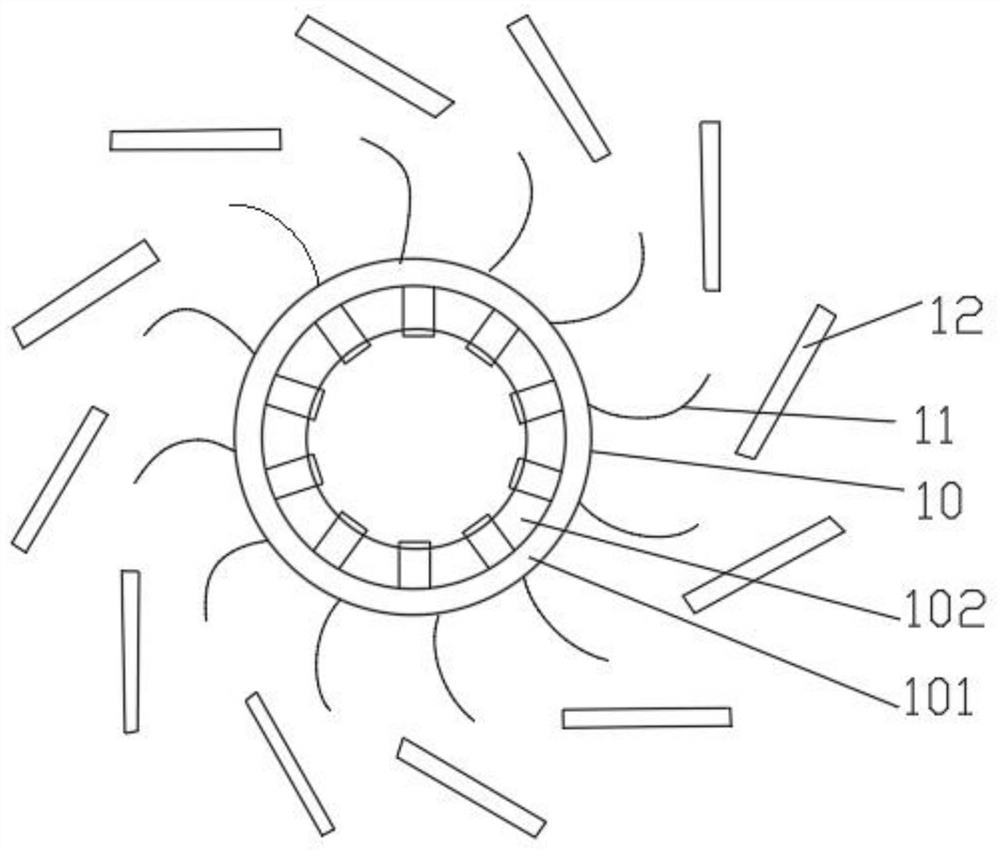

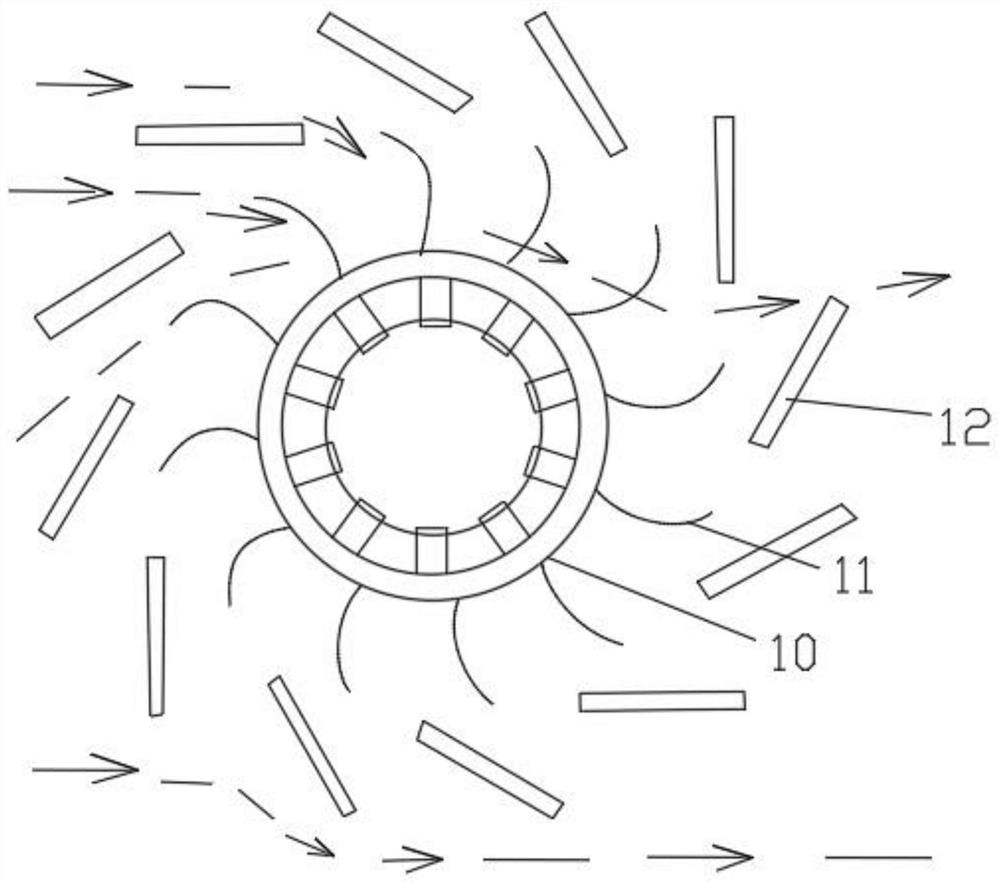

[0032] Please refer to Figure 2-4 , the first embodiment provides a vertical shaft wind power generator 1, including an outer rotor motor device 10, blades 11 arranged at intervals along the circumferential direction on the outer wall surface of the outer rotor motor device 10; and along the blades 11 The deflector 12 arranged on the periphery of the

[0033] Wherein, the number of the deflectors 12 is consistent with the number of the blades 11, and each deflector 12 is set in one-to-one correspondence with the corresponding blades 11; Conditions and cost considerations N=3, 4, 5, 6, 8, 9, 10, 12, it is not necessary that the number of vanes and deflectors be equal.

[0034] The cross-section of the blade 11 is a concave curved surface (the cross-section of the blade is a curved surface, and it is the concave surface of the above-mentioned curved surface that is propelled by the wind), and a plurality of the deflectors 12 are distributed with an inclination angle around the...

Embodiment 2

[0055] Please refer to Figure 6-Figure 8 , this embodiment 2 provides a distributed energy storage station device, including the vertical axis wind power generator 1 provided in the above embodiment 1, the support body 2 arranged at the bottom of the vertical axis wind power generator and the The energy storage base 3 at the bottom and the energy storage photovoltaic interface; the inside of the energy storage base 3 is provided with an energy storage system 4; the vertical axis wind generator is electrically connected to the energy storage system through wire lines; the photovoltaic panel It is electrically connected with the energy storage system 4 through wires; the energy storage system 4 includes multiple storage battery packs and other structures, which will not be repeated here.

[0056] The second embodiment provides a distributed energy storage station device, which installs the energy storage system 4 inside the energy storage base 3. The airtight anti-theft functi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com