Thermal power plant high-temperature/high-pressure pipeline state monitoring and risk assessment system

A technology of risk assessment system and monitoring system, which is applied in the field of high-temperature/high-pressure pipeline condition monitoring and risk assessment system in thermal power plants, to improve safety and reliability, facilitate scientific guidance of operation, and liberate manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

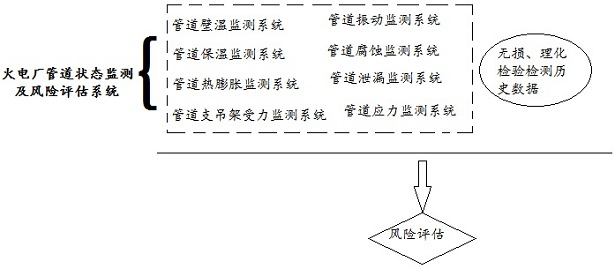

[0030] see figure 1 , in this embodiment, a high temperature / high pressure pipeline condition monitoring and risk assessment system in a thermal power plant, including a pipeline wall temperature monitoring system, a pipeline insulation monitoring system, a pipeline thermal expansion monitoring system, a pipeline support and hanger force monitoring system, and a pipeline vibration monitoring system system, pipeline corrosion monitoring system, pipeline leakage monitoring system, pipeline stress monitoring system and pipeline non-destructive and physical and chemical testing historical data analysis system.

[0031] Pipeline wall temperature monitoring system, the wall temperature monitoring device is installed on the outer surface of the pipeline, close to the pipeline, using the temperature difference between the temperature of the medium inside the pipeline and the temperature difference of the outer wall of the pipeline to control the temperature rise and fall rate, and iden...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com