Feeding device for realizing automatic tray changing

A feeding device and automatic technology, applied in conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of high labor intensity, insufficient automation, and high labor costs, to improve the degree of automation, liberate manpower, and eliminate height differences. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

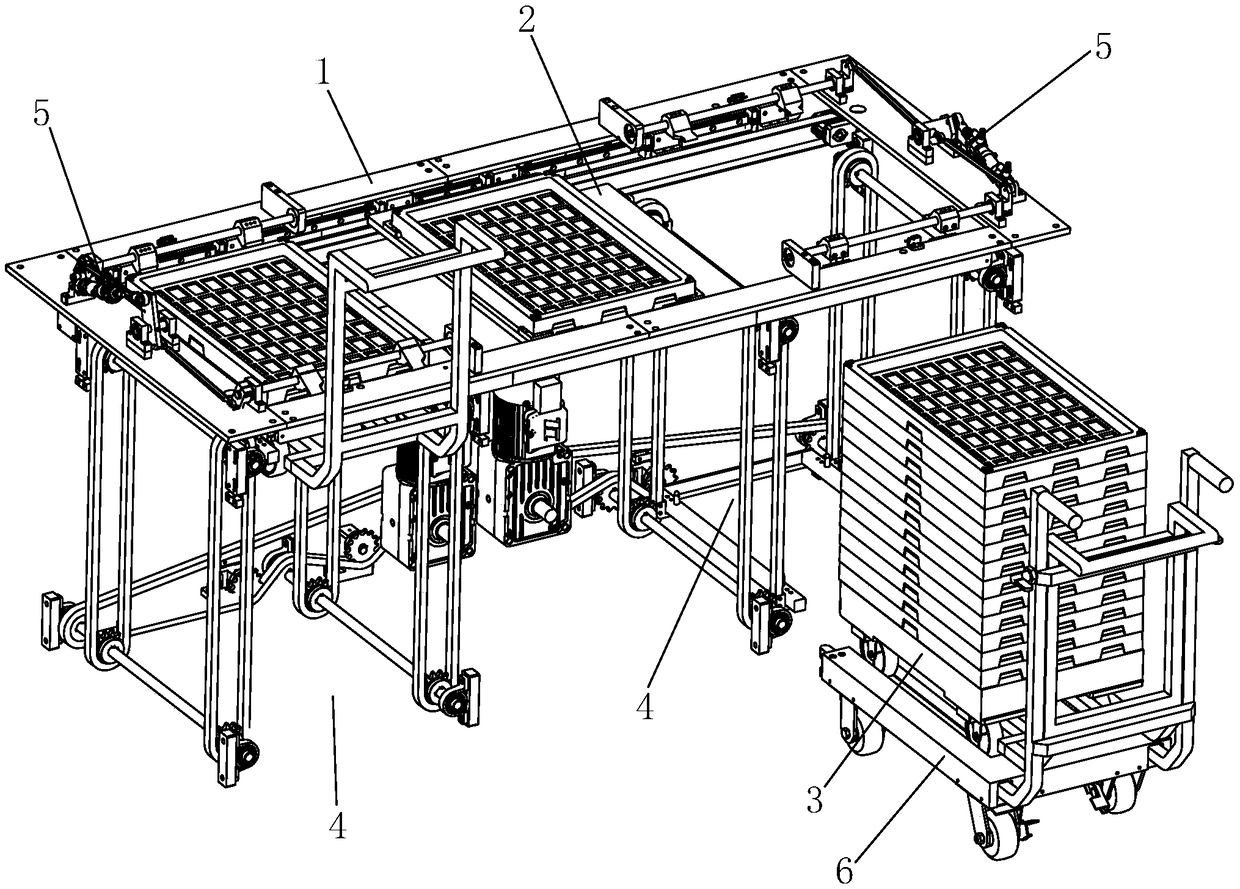

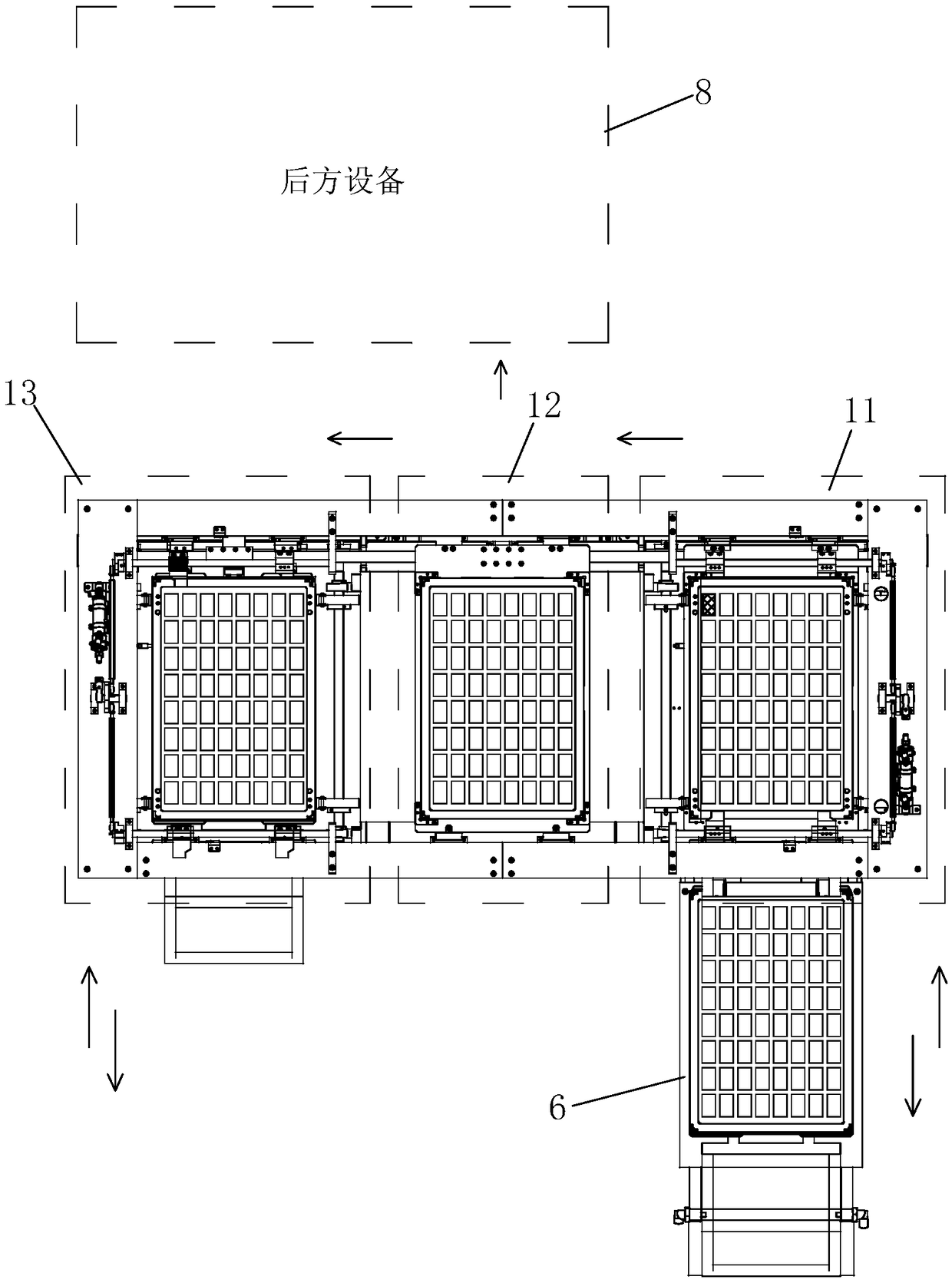

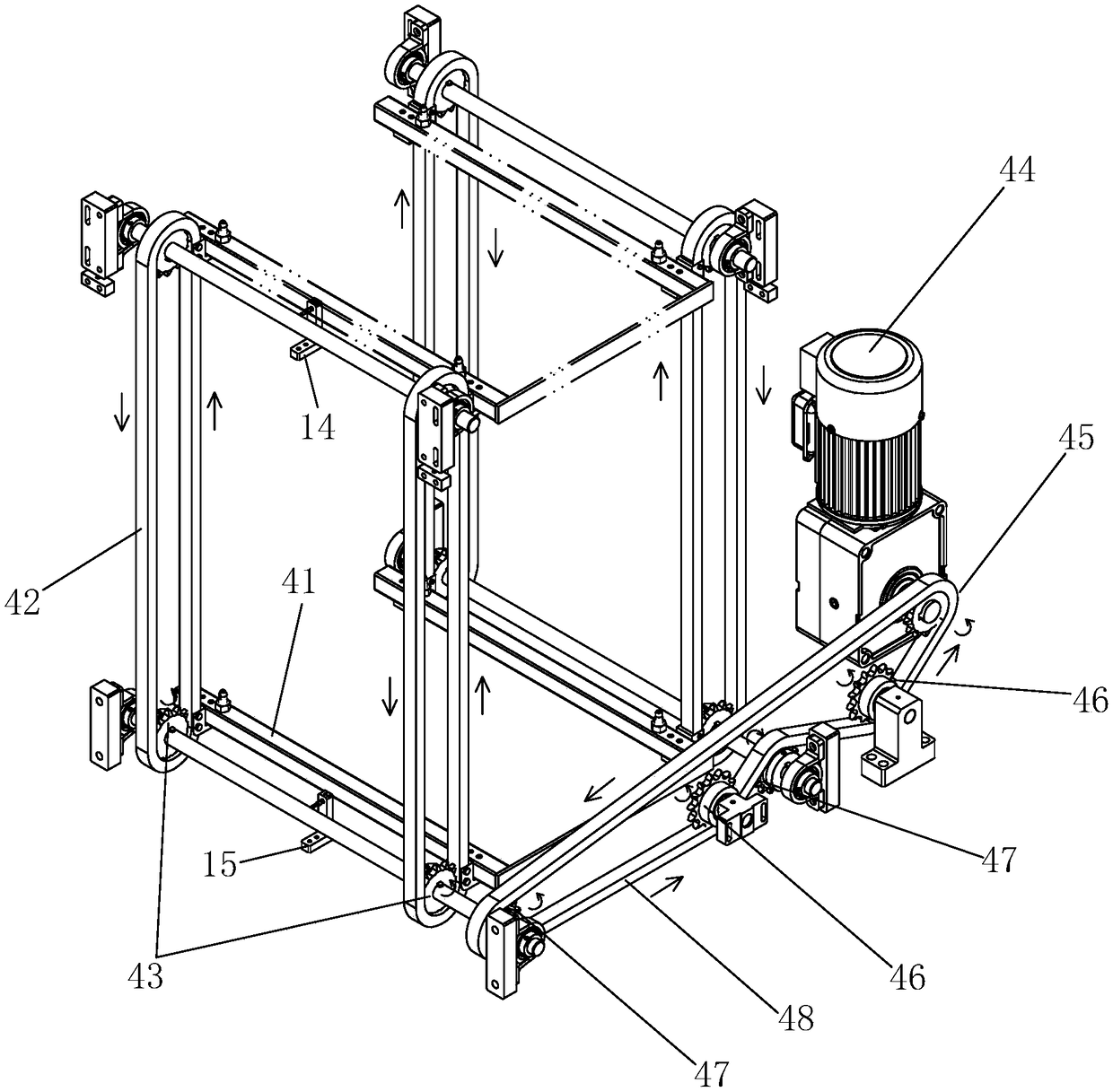

[0040] For examples, see Figure 1-Figure 15 As shown, a feeding device that realizes automatic disk change of the present invention includes a frame 1, and the frame 1 is provided with a preparation area 11, a closing area 13 and a feeding area 12, wherein the preparation area 11 and the closing area 13 , The feeding area 12 is located in the same direction, and the feeding area 12 is located between the preparation area 11 and the closing area 13 for connecting and cooperating with the rear equipment 8. The invention also includes:

[0041] Workbench 2 is used to transport full or empty trays to the feeding area 12 or empty trays to the closing area 13. The workbench 2 is slidably arranged on the frame 1 and is connected with a mobile drive mechanism 7 , The moving drive mechanism 7 drives the workbench 2 to move to the preparation area 11, the closing area 13, or the feeding area 12;

[0042] Several lift trucks 3 for loading full trays or storing empty trays;

[0043] Two lifti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com