Power battery package leakage detection equipment

A power battery and leak detection technology, applied in the field of power batteries, can solve problems such as slow detection efficiency, high work difficulty, and high labor intensity, and achieve the effects of increasing maintenance costs, reducing labor intensity, and increasing work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

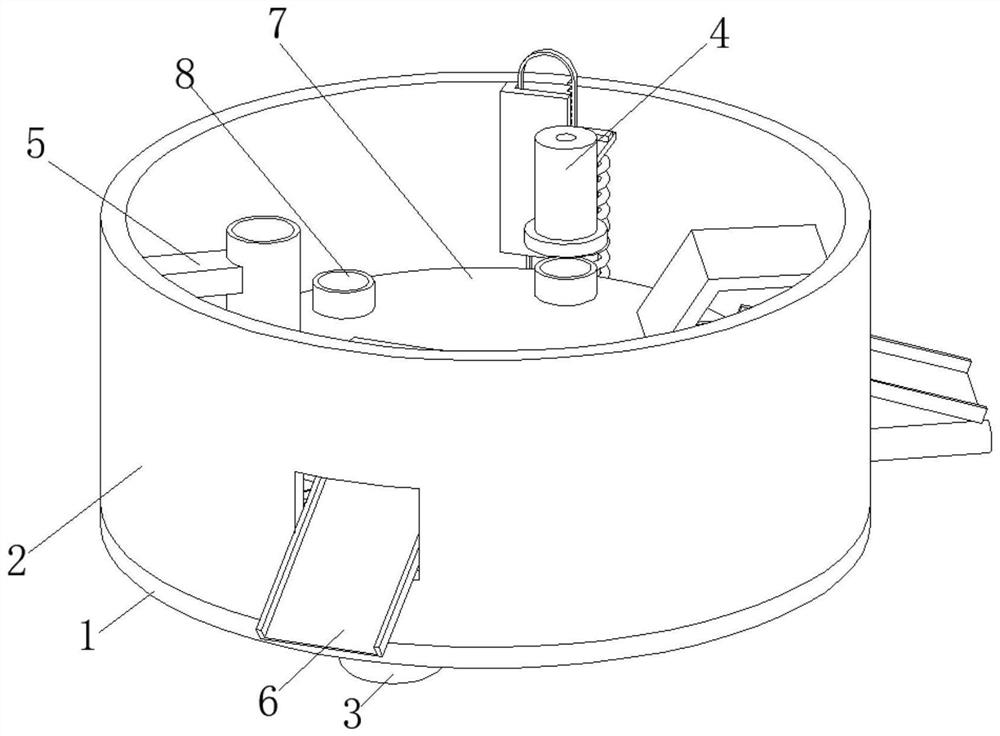

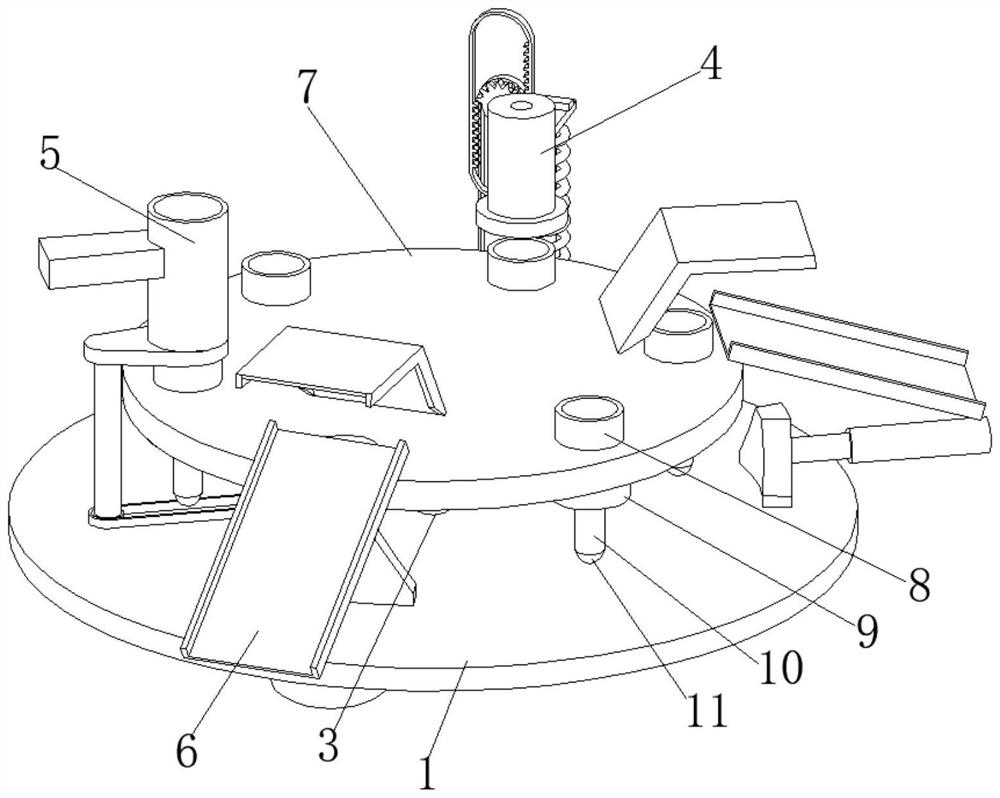

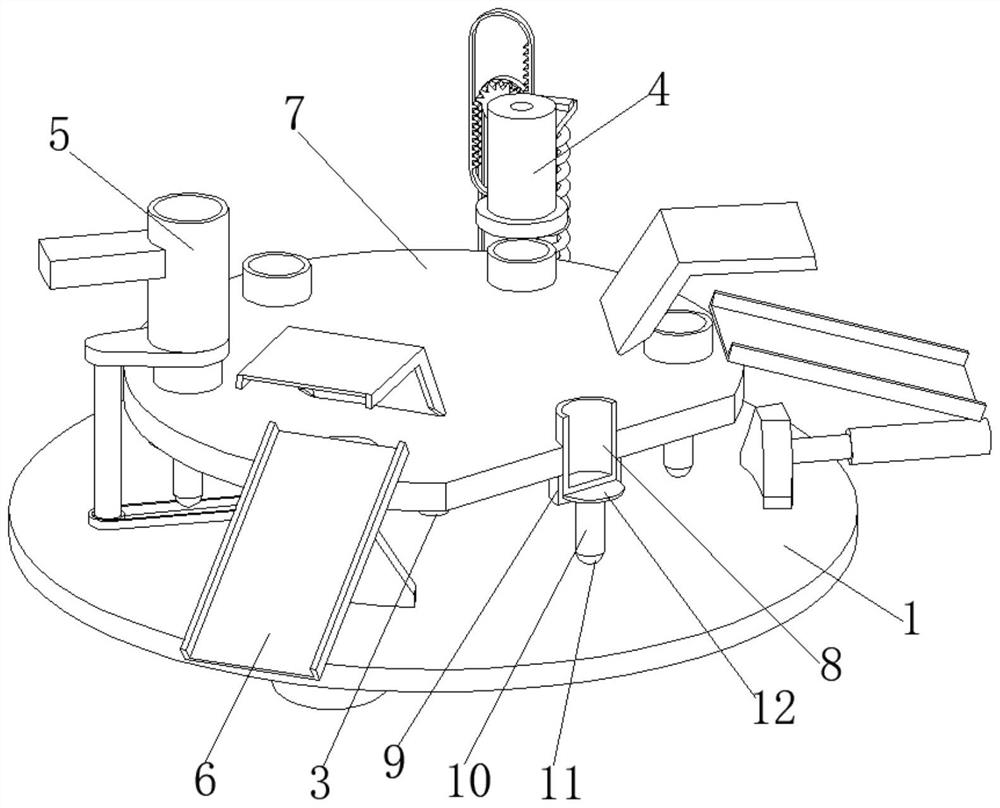

[0030] A power battery packaging leak detection equipment, such as Figure 1-Figure 6 As shown, including the mounting plate 1, the top of the mounting plate 1 is fixedly installed with a coaming plate 2, the bottom of the mounting plate 1 is provided with a transmission mechanism 3, and the inner wall of the coaming plate 2 is respectively provided with a detection mechanism 4, a feeding mechanism 5 and a discharge mechanism. mechanism 6, and the feeding mechanism 5 and the discharging mechanism 6 are respectively located on the left side and the front of the detection mechanism 4, the top of the transmission mechanism 3 is provided with a turntable 7, the inner wall of the turntable 7 is slidingly connected with a packaging shell 8, and the bottom of the turntable 7 A tray 9 is welded, the inner wall of the tray 9 is slidably connected with a support column 10, the bottom end of the support column 10 is rotatably connected with a ball 11, and the top of the support column 10 ...

Embodiment 2

[0044] Such as Figure 6-Figure 7 As shown, on the basis of Embodiment 1, in this embodiment, the surface of the No. 4 pulley 51 is connected to the surface of the double-layer pulley 37 through a belt, and the axis of the No. 4 pulley 51 is connected to the top of the mounting plate 1 in rotation. , the upper surface of the second cam 53 is in contact with the bottom end of the feed pipe 55 .

[0045] The feeding pipe 55 is located directly above the tray 9, so the packaging shell 8 can directly fall on the tray 9 to prevent it from falling off, and then cause it to not be loaded, causing the device to fail to work normally, and the practicability is greatly reduced.

[0046] The discharge mechanism 6 includes a No. 1 top board 61 and a No. 2 top board 62 . The surface of the No. 2 top board 62 is welded with an electric push rod 63 .

[0047] Through the discharging mechanism 6, the detected packaging shells 8 can be automatically discharged and classified, and workers are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com