Leakage detector of lighter

A leak detector and lighter technology, applied in instruments, measuring devices, and by measuring the acceleration and deceleration rates of fluids, can solve the problems of low detection efficiency, high labor intensity, and missed detection, and achieve high detection efficiency and good reliability. , the effect of high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

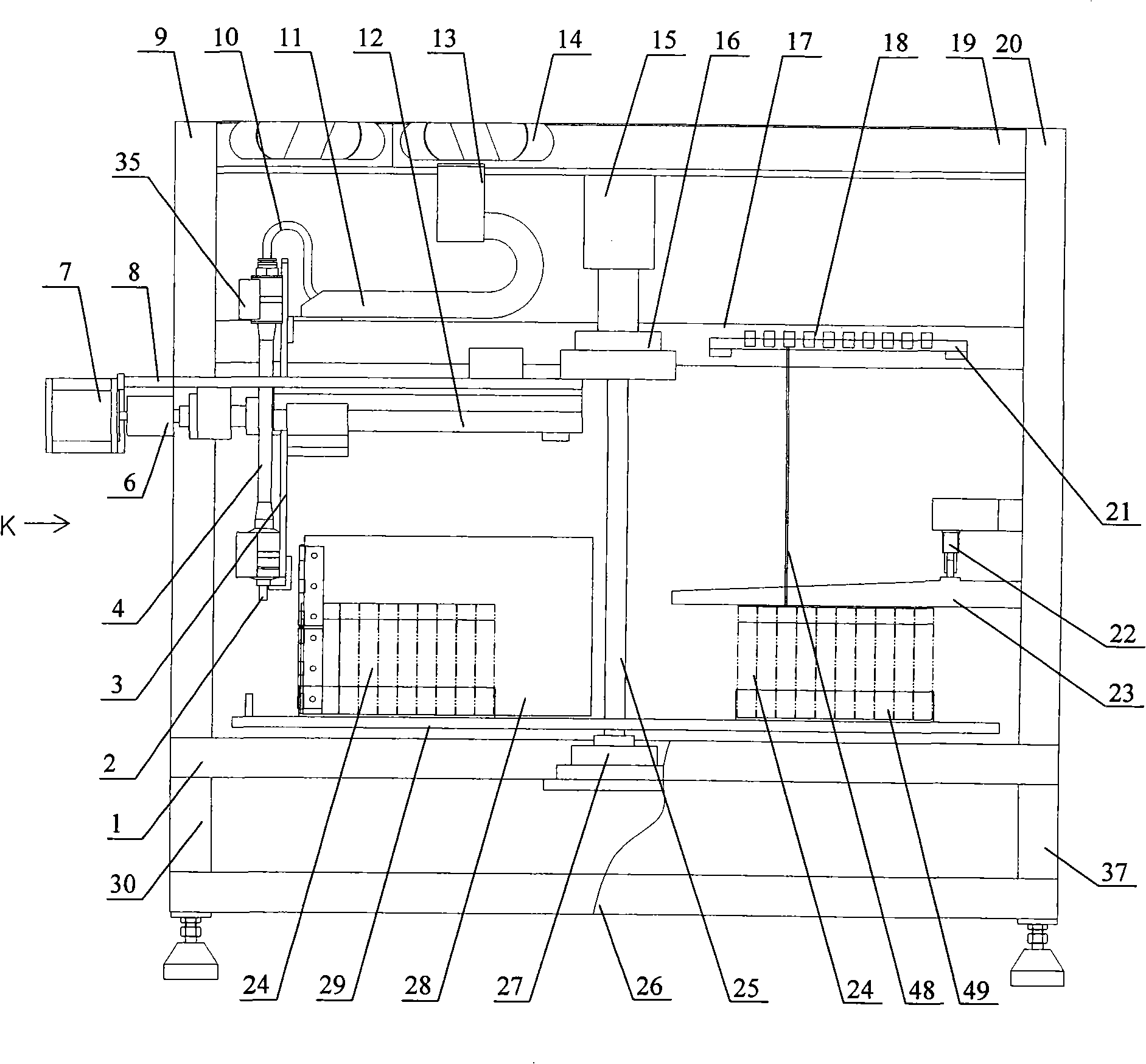

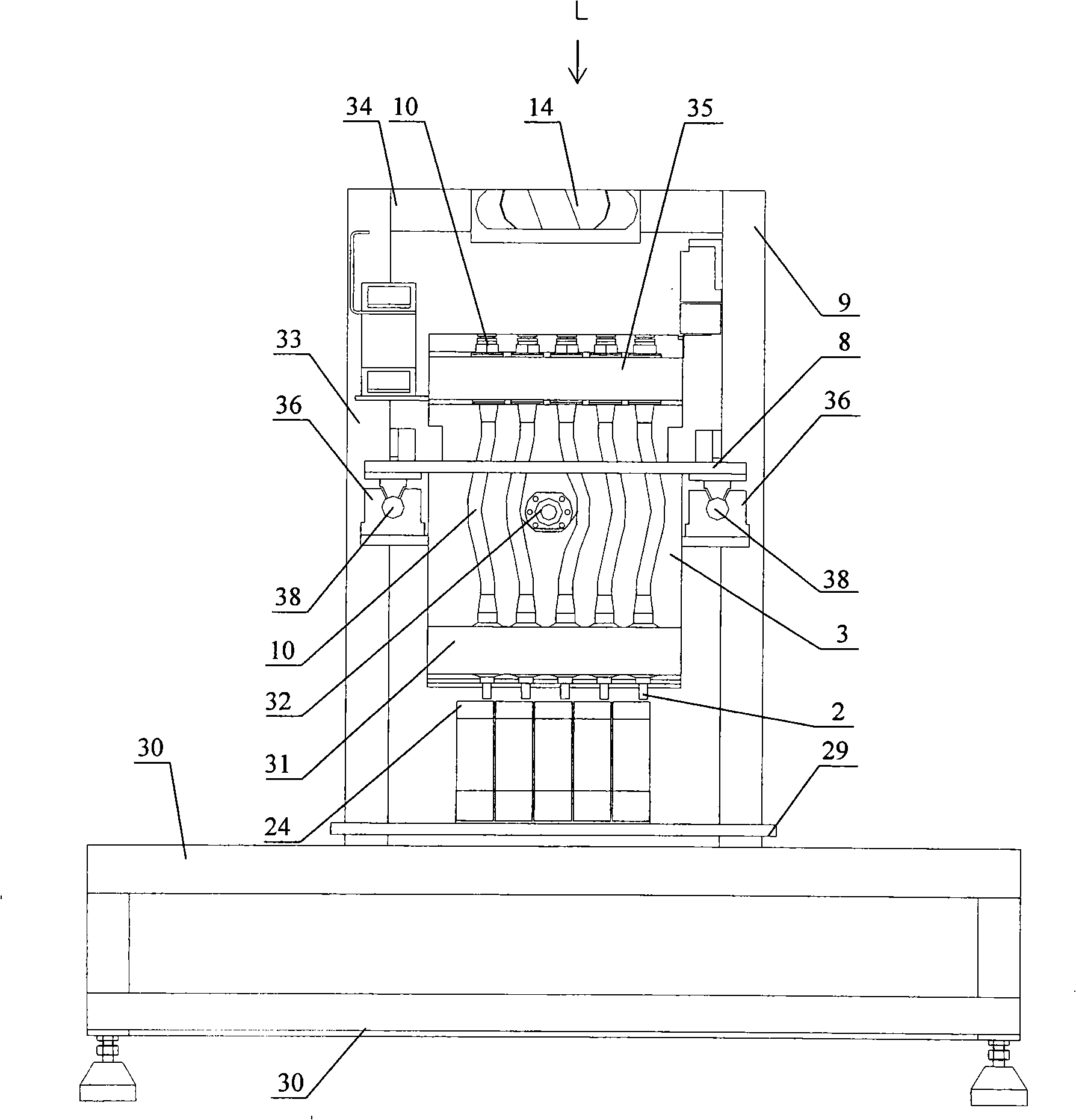

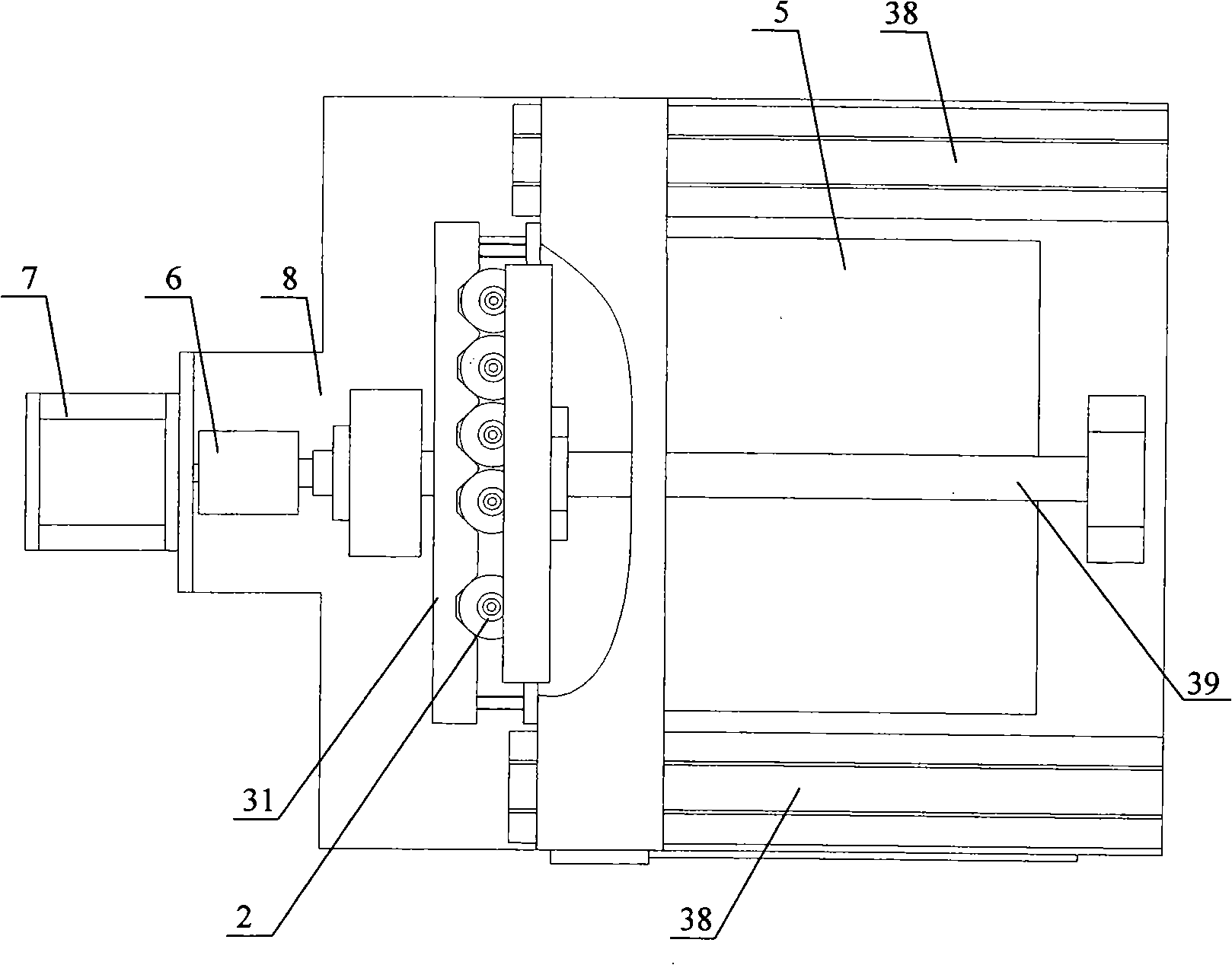

[0034]After the test starts, the boxed lighter 24 to be tested is placed in the clamping frame 49, and the second stepper motor 27 drives the turntable 29 to rotate. In this process, if the height of the lighter 24 is greater than the standard height, the lighter 24 drives the height detection ruler 23 to touch the limit switch 22, and the limit switch 22 sends the signal to the microprocessor, and the microprocessor controls the second stepper motor 27 to stop. The buzzer works, and the operator adjusts the posture of the lighter 24; otherwise, the detection continues. The microprocessor controls the first stepper motor 7, the automatic detection unit moves to the right end along the screw mandrel 39, the moving block 46 pushes the rotating block 45 to rotate, the door 28 is opened, and the lighter 24 to be tested enters the negative pressure generating unit simultaneously; When the moving block 46 falls off, the door 28 returns to the closed state under the effect of the doo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com