Automatic logistics system

A logistics system and conveyor technology, applied in the field of logistics systems, can solve problems such as single function, and achieve the effects of strong practicability, ingenious structural design and excellent use effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

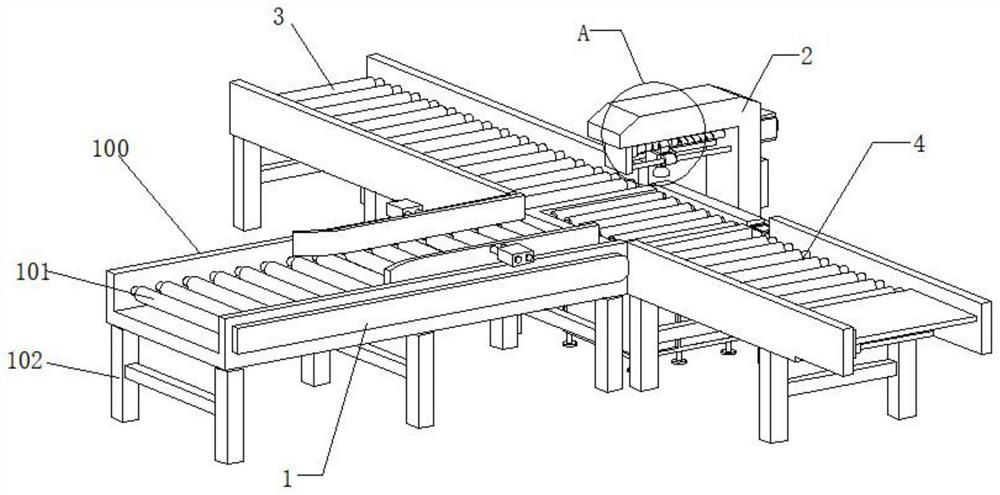

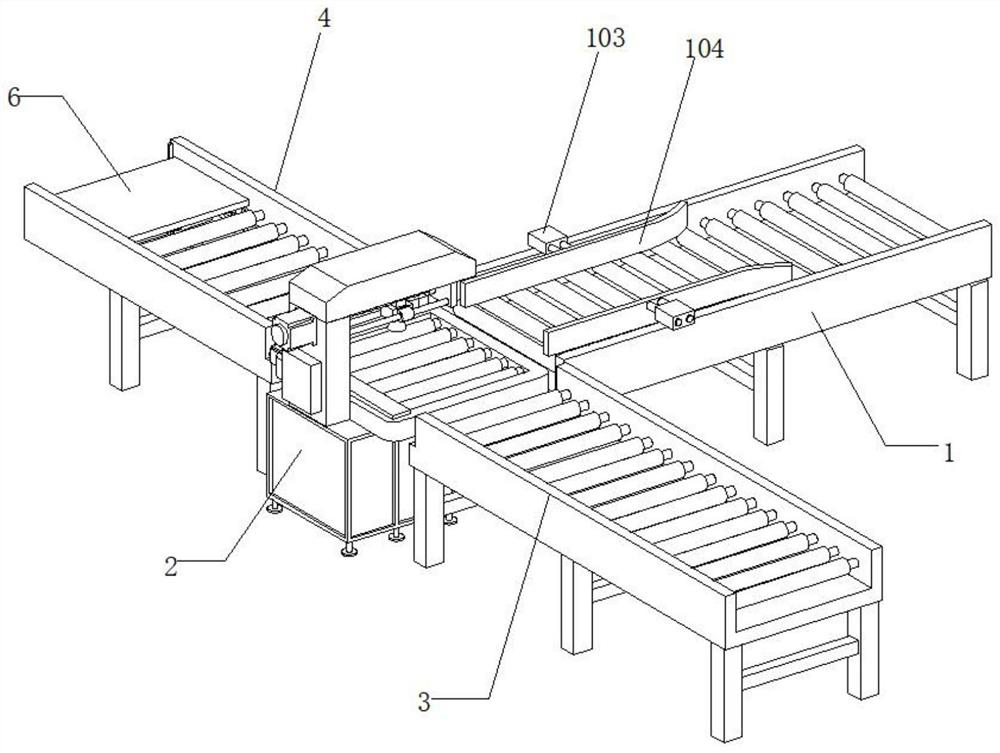

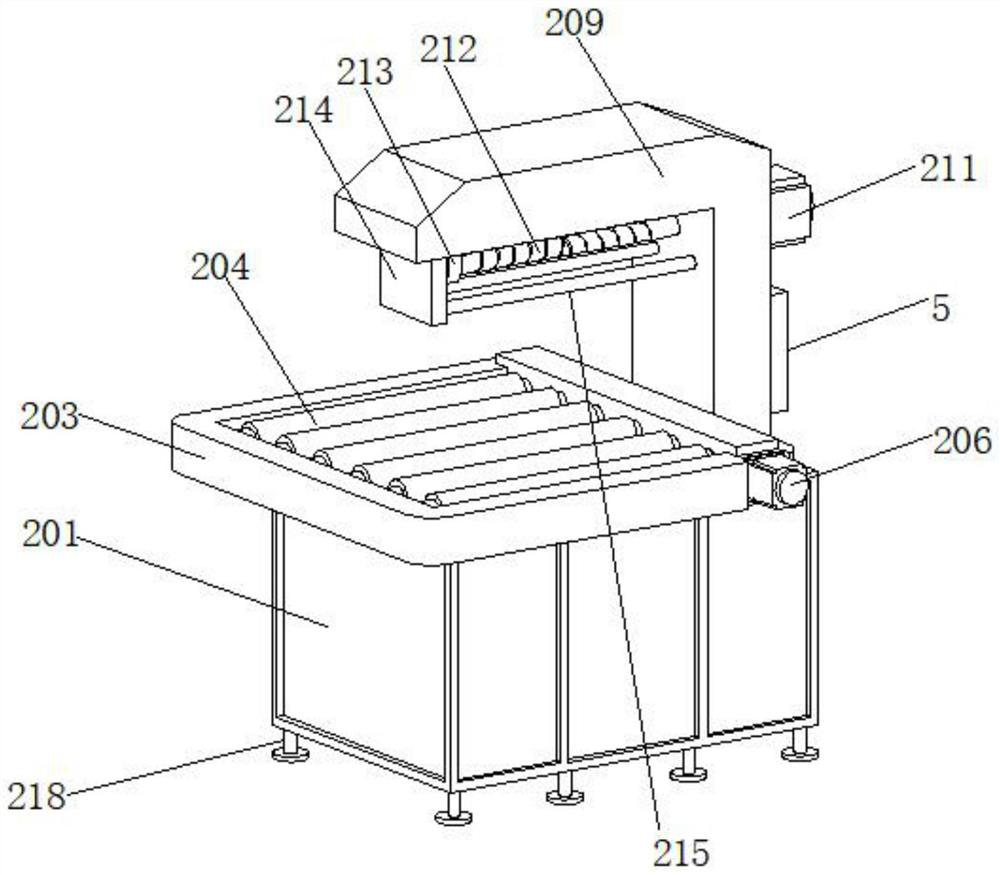

[0039] This embodiment 1 discloses an automated logistics system, refer to the attached figure 1 And attached figure 2 , its main equipment includes feeding conveyor 1, sorting and testing device 2, unqualified product conveyor 3, qualified product conveyor 4 and central processing unit 5. Among them, the feeding conveyor 1, the qualified product conveyor 3, and the qualified product conveyor 4 are respectively connected with the three sides of the sorting and testing device 2, and the feeding conveyor 1, the sorting and testing device 2, and the unqualified product are conveyed Machine 3 and qualified product conveyor 4 have formed a T-shaped delivery logistics route. Among them, the feeding conveyor 1, the unqualified product conveyor 3, and the qualified product conveyor 4 all include a U-shaped frame 100, and the U-shaped frame 100 is connected with a plurality of feeding rollers 101 for rotation at intervals, and each U-shaped Support rods 102 are provided on the lower...

Embodiment 2

[0043] Embodiment 2 discloses an improved automated logistics system based on Embodiment 1. Refer to the attached figure 1 And attached figure 2 , its main equipment includes feeding conveyor 1, sorting and testing device 2, unqualified product conveyor 3, qualified product conveyor 4 and central processing unit 5. Among them, the feeding conveyor 1, the qualified product conveyor 3, and the qualified product conveyor 4 are respectively connected with the three sides of the sorting and testing device 2, and the feeding conveyor 1, the sorting and testing device 2, and the unqualified product are conveyed Machine 3 and qualified product conveyor 4 have formed a T-shaped delivery logistics route. Among them, the feeding conveyor 1, the unqualified product conveyor 3, and the qualified product conveyor 4 all include a U-shaped frame 100, and the U-shaped frame 100 is connected with a plurality of feeding rollers 101 for rotation at intervals, and each U-shaped Support rods 102...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com