Large-section underground space non-excavation construction prestress bunching structure and construction method

A technology of underground space and prestressed beams, applied in underground chambers, earthwork drilling, shaft equipment, etc., can solve problems such as cumbersome procedures, affecting the stress state, opening and leakage between pipe joints, etc., and achieve efficient project management The effect of convenience, high degree of mechanization and high engineering quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

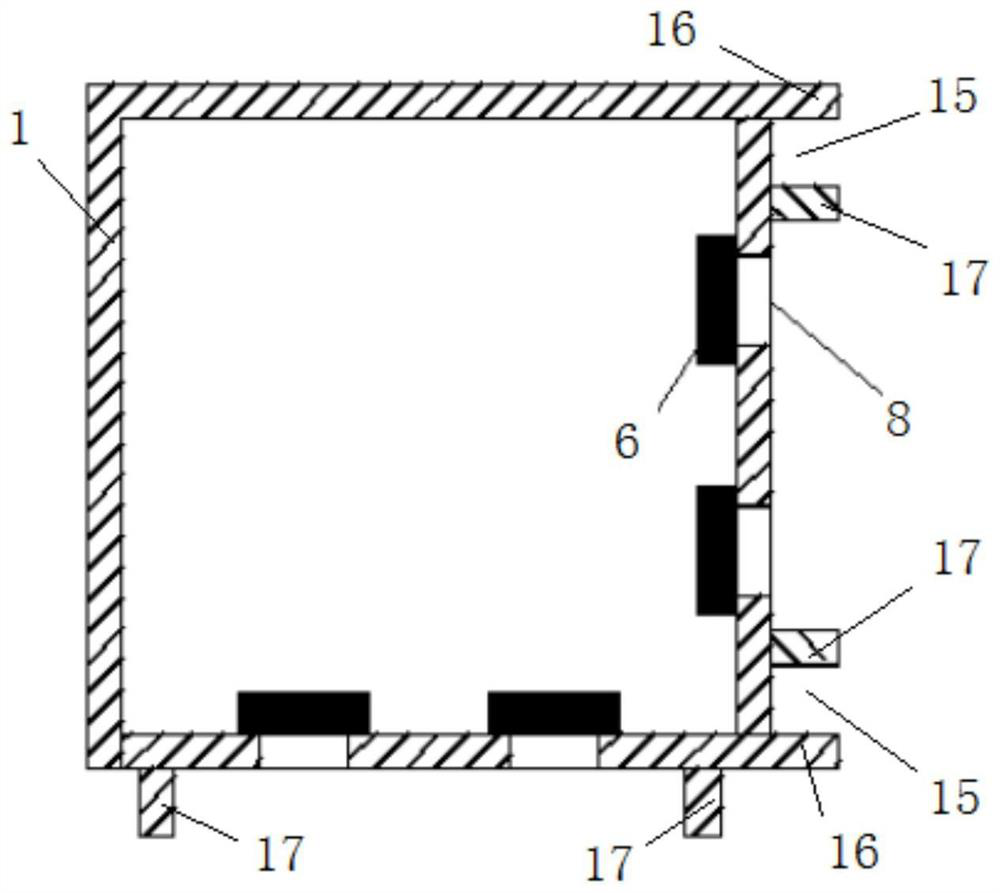

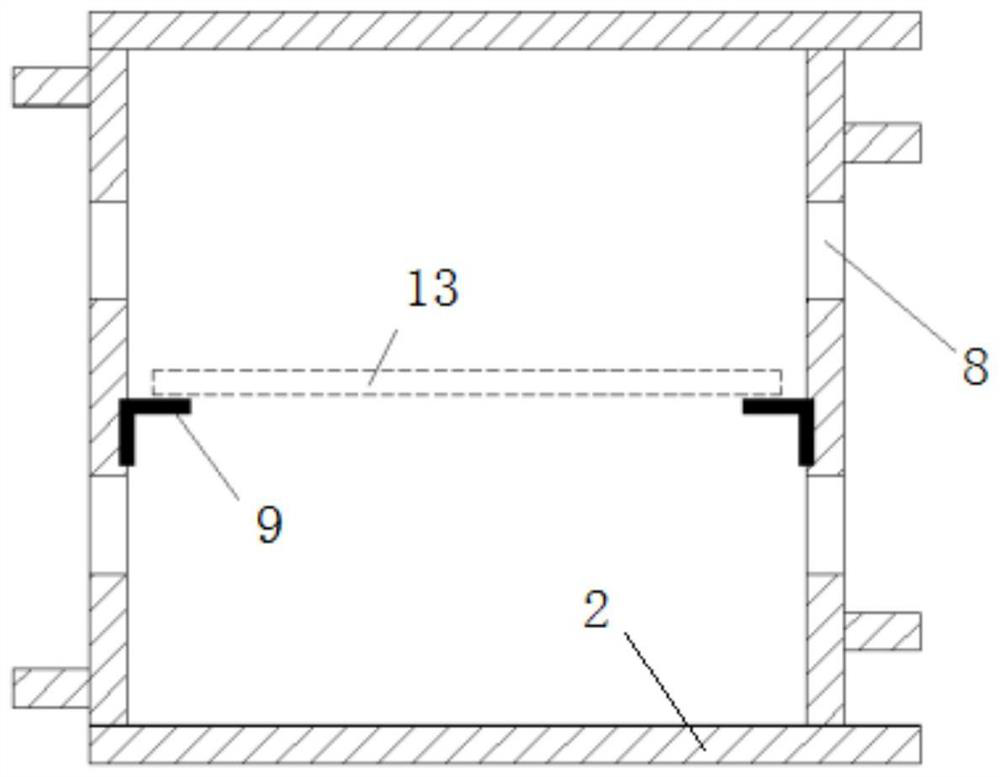

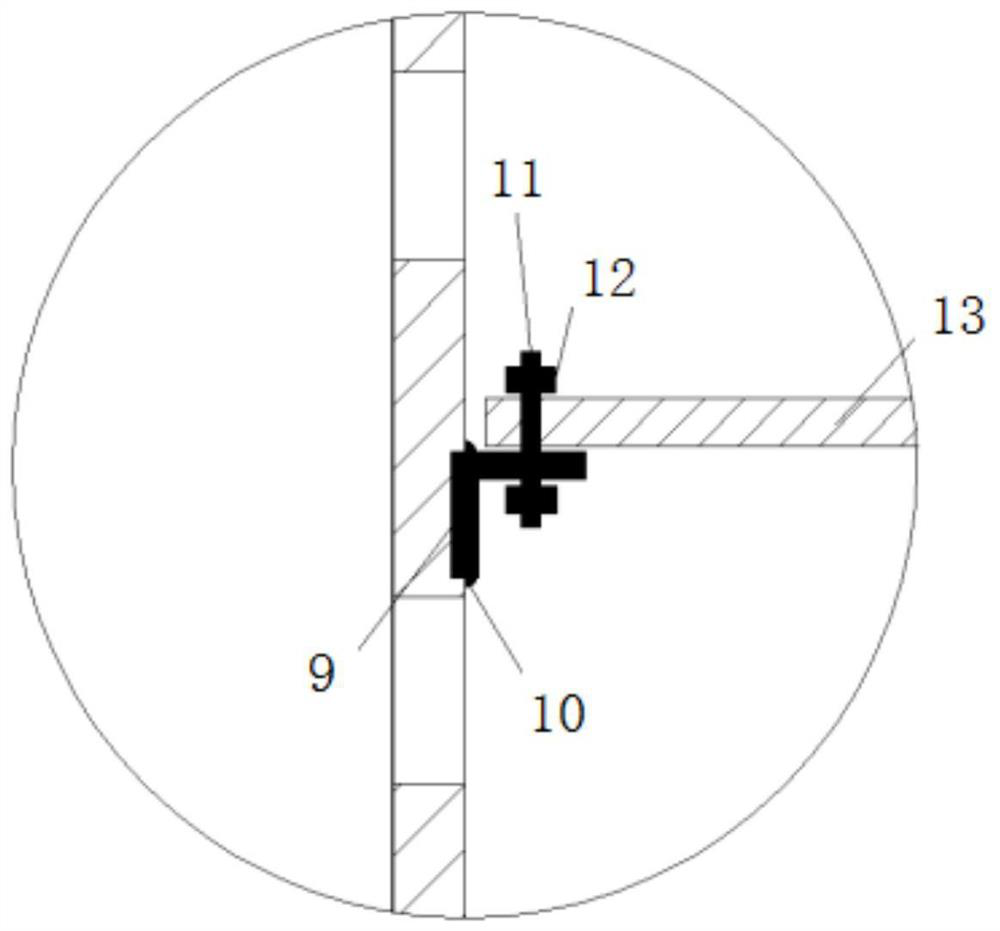

[0044] Such as Figure 1 to Figure 5 As shown, the prestressed bundled structure of the large-section underground space trenchless construction includes a plurality of corner pipes 1, a plurality of square steel pipes 2 and a plurality of post-tensioned prestressed bundles.

[0045] Wherein, a plurality of angular pipes 1 and a plurality of square steel pipes 2 form a tubular structure with a convex polygonal cross section;

[0046] Each corner tube 1 is arranged at the corner position of the cross section of the tubular structure; a limit structure is provided between each corner tube 1 and the adjacent square steel tube 2;

[0047] A plurality of square steel pipes 2 are arranged corresponding to each straight side of the cross-section of the tubular structure; a limiting structure is provided between every two adjacent square steel pipes 2;

[0048] A plurality of square steel pipes 2 corresponding to each straight side of the cross-section of the tubular structure, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com