Resin line formed from a corrugated pipe

A technology of resin tubes and corrugated tubes, applied in the direction of pipes/pipe joints/fittings, hoses, pipes, etc., can solve the problems of unfavorable imprinting and collapse of materials, and achieve the effect of simplifying diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

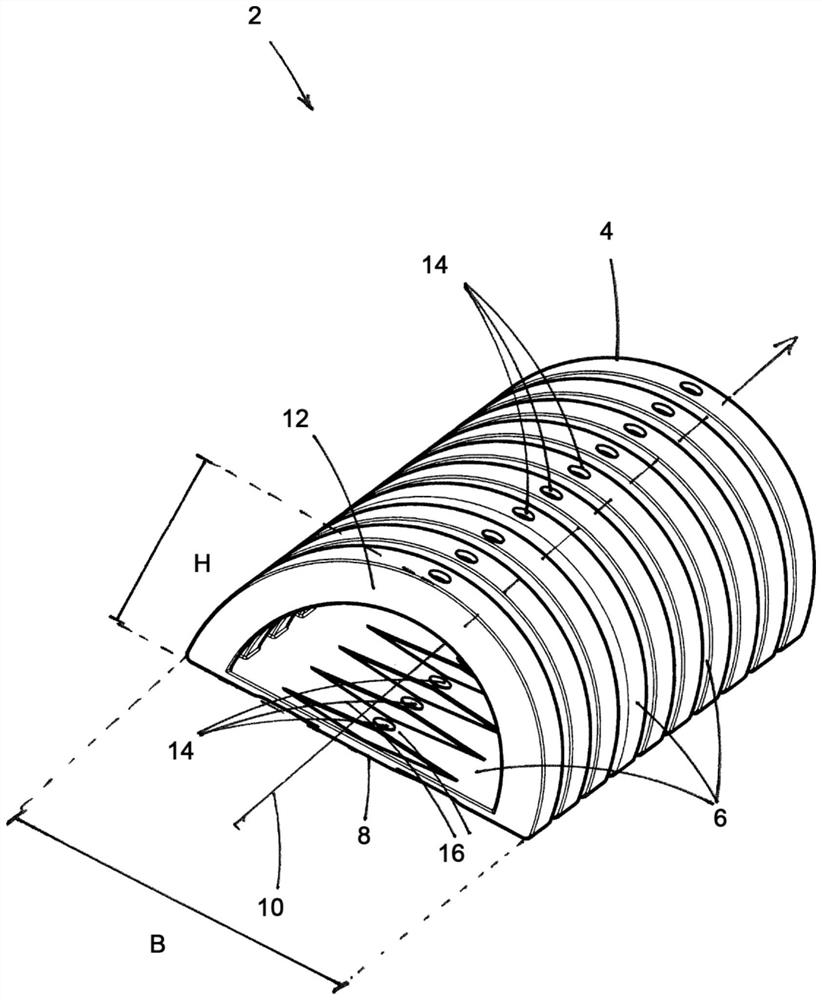

[0030] exist figure 1 The section of the resin line 2 formed by the bellows 4 is shown in . The corrugated tube 4 has a wall made of corrugated material. In this case, the corrugations can have a circular configuration or, as in the exemplary embodiment, have a corrugated angular cross-sectional shape. It is important that the wall 6 is not designed to be smooth, but the corrugated shape enables the bellows 4 to bend without kinks occurring in the wall 6 which would interfere with a good flow and could lead to the leakiness.

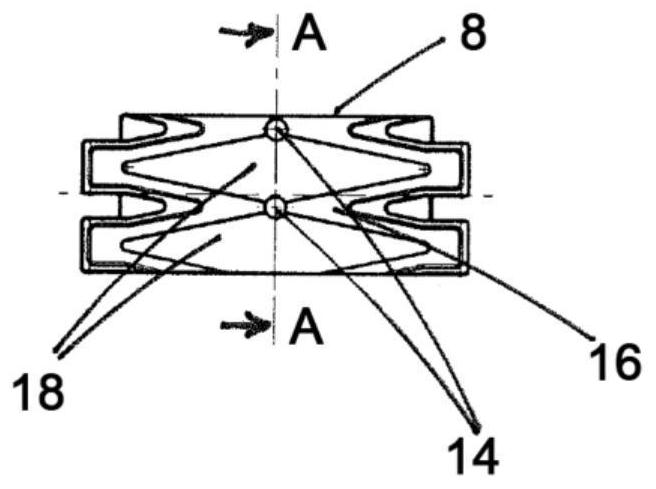

[0031] As can be seen from obliquely above in the view, the bellows 4 has a rotationally non-symmetrical cross-sectional shape transversely to the longitudinal center axis 10 due to the fact that the wall 6 is divided into two parts. In the first part, the wall 6 is provided along the circumference of the wall 6 with a truncated base 8 extending over the length of the bellows 4 in a direction transverse to the longitudinal center axis 10, and in the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com